Construction method for dry and wet type composite connecting assembly-type building

A technology of composite connection and construction method, which is applied in the direction of construction and building construction, can solve the problems of insufficient compressive strength, insufficient corrosion resistance, and high cost of raw materials, and achieve the effects of easy quality assurance, reduced self-weight, and improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A dry-wet compound connection assembled structure construction method, comprising the following steps:

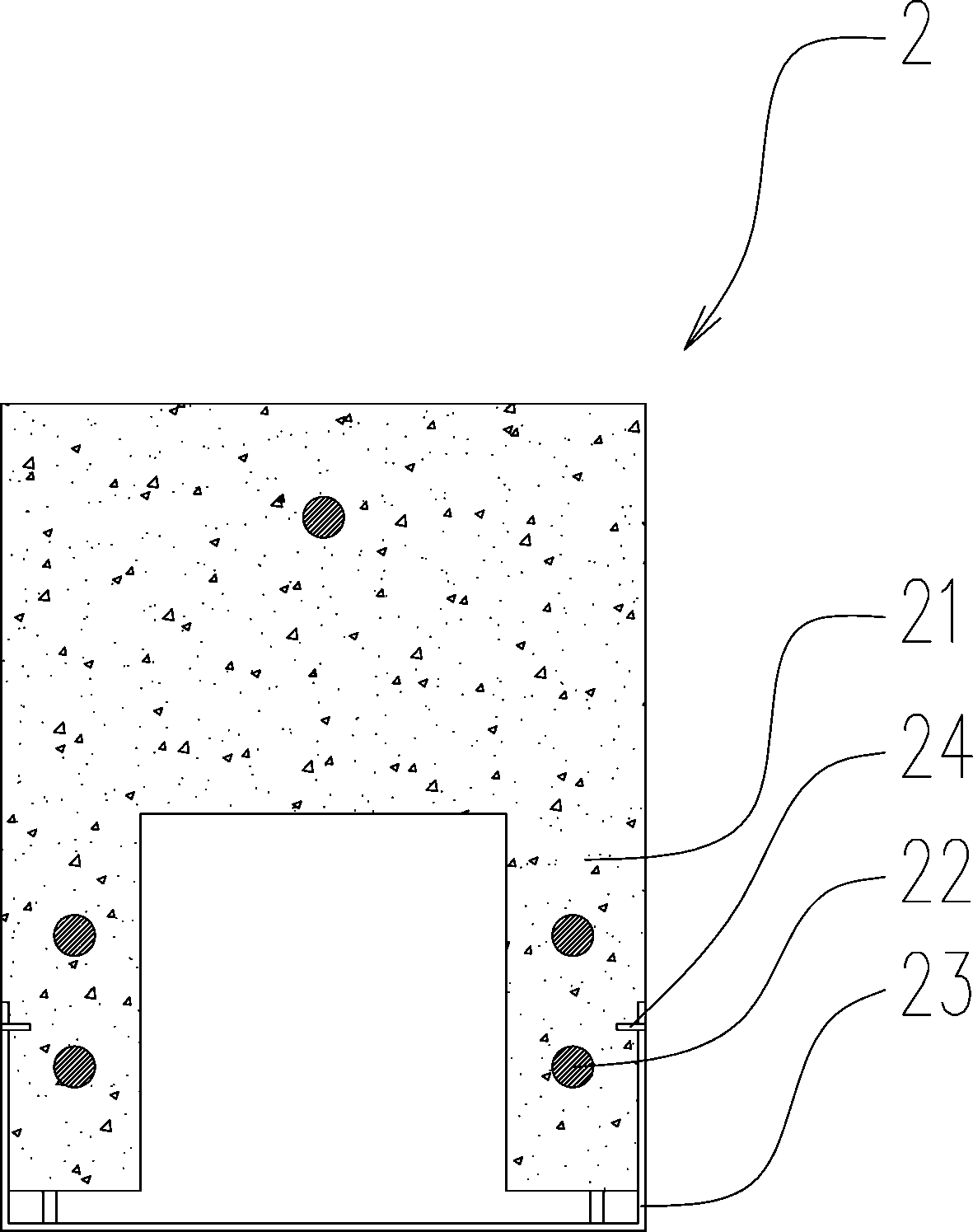

[0042] s1. Prefabricated components in the workshop, including column 1, beam 2, floor 5, inner layer of shear wall 3, and outer layer of shear wall 3;

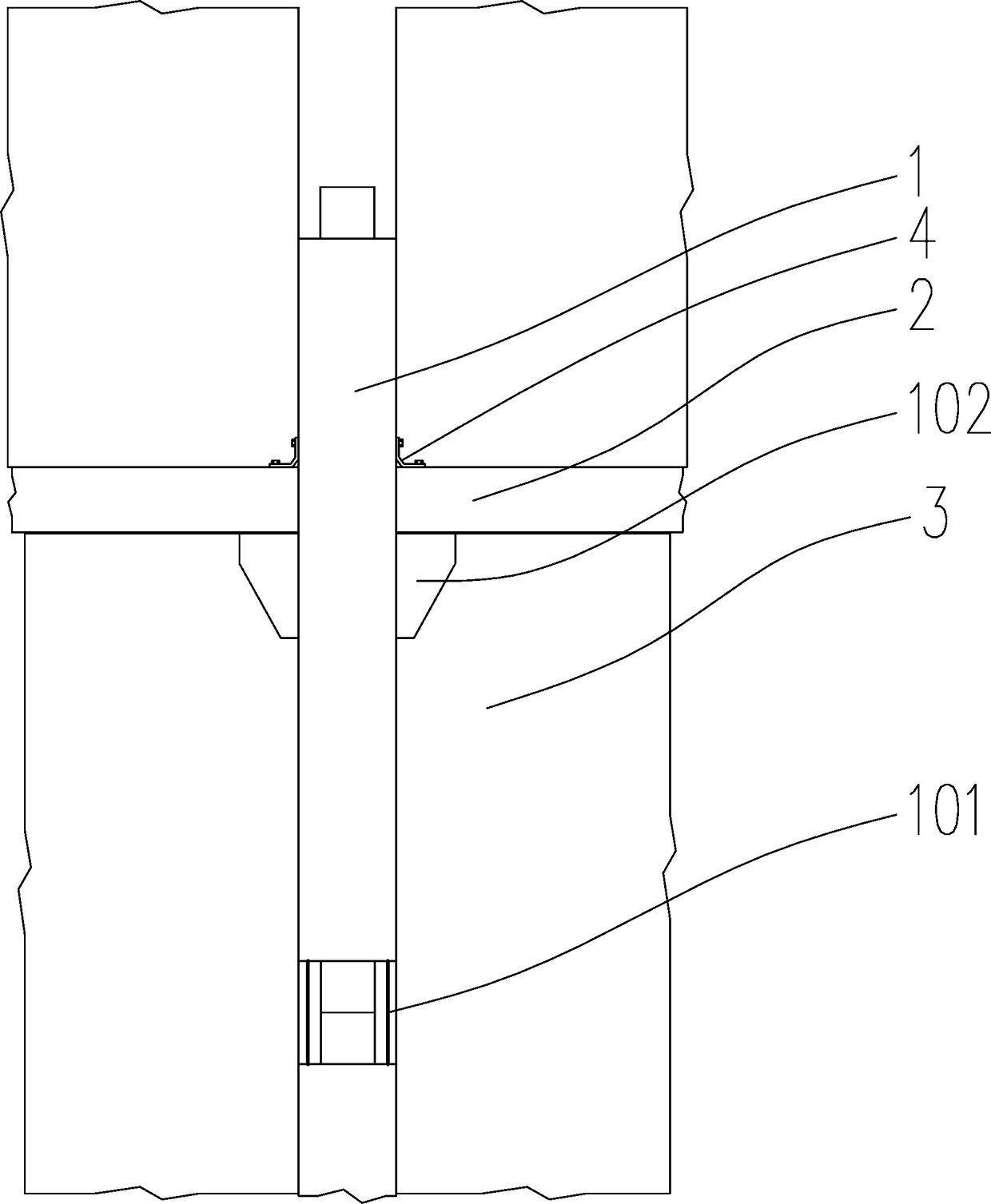

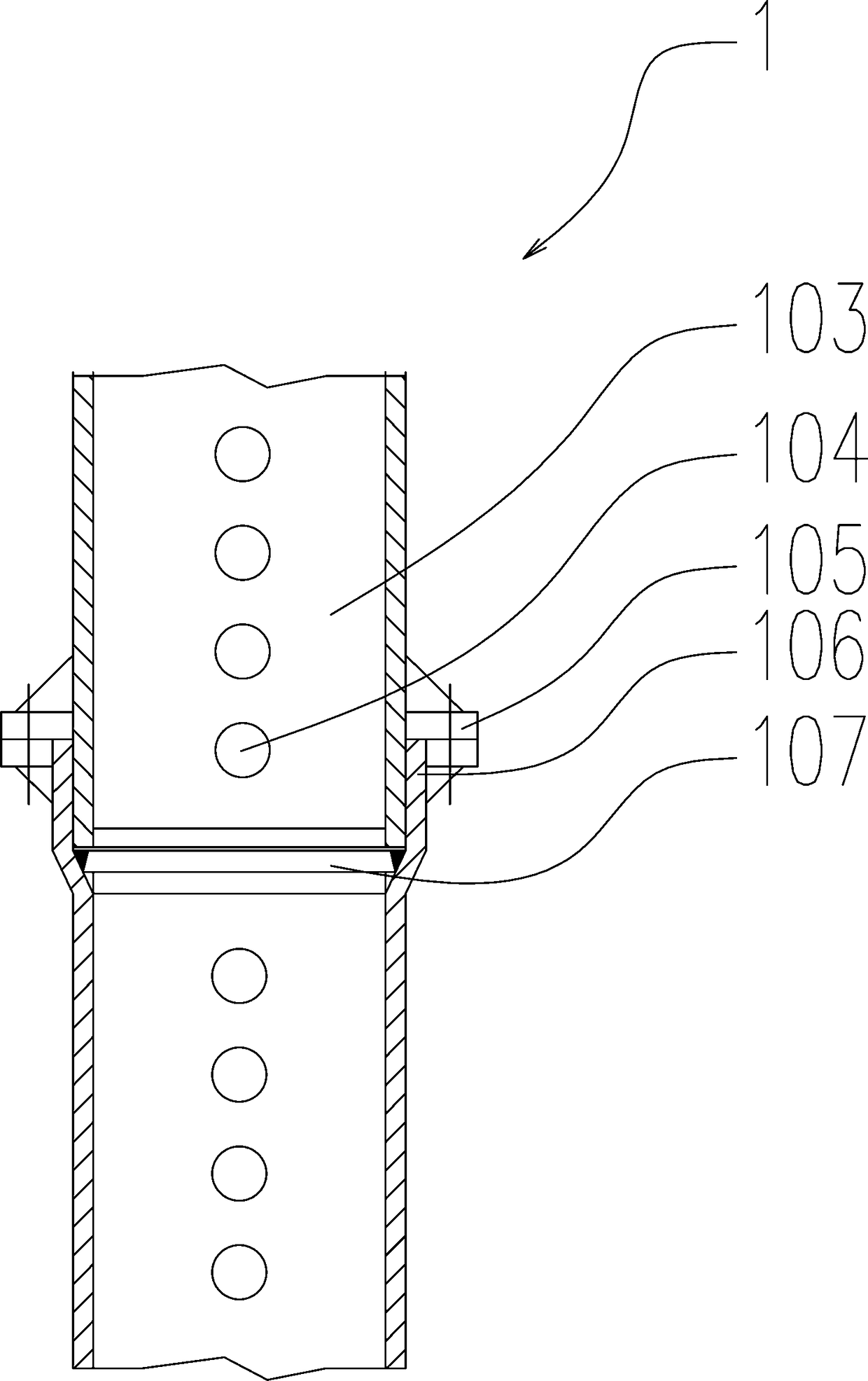

[0043] Such as figure 1 Among them, the joint position of the column 1 is located between floors, a socketed steel pipe 103 is arranged inside the column 1, and column reinforcement 101 is arranged around the socketed steel pipe 103, and concrete is poured inside and outside of the socketed steel pipe 103, The socketed steel pipe 103 at the joint position and the end of the column reinforcement 101 are exposed, and the column 1 is provided with a corbel support 102 for supporting the beam 2;

[0044] The preferred solution is as figure 2 Among them, at least one end of the sleeved steel pipe 103 is provided with a diameter-expanding end 106 for mutual socketing, and a connecting flange 105 is provided at a distan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap