Multi-optical axis automatic calibration system and multi-optical axis automatic calibration method

An automatic calibration, multi-optical axis technology, applied in the field of optical calibration, can solve the problems of high cost, unsuitable for field handling test, large size and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

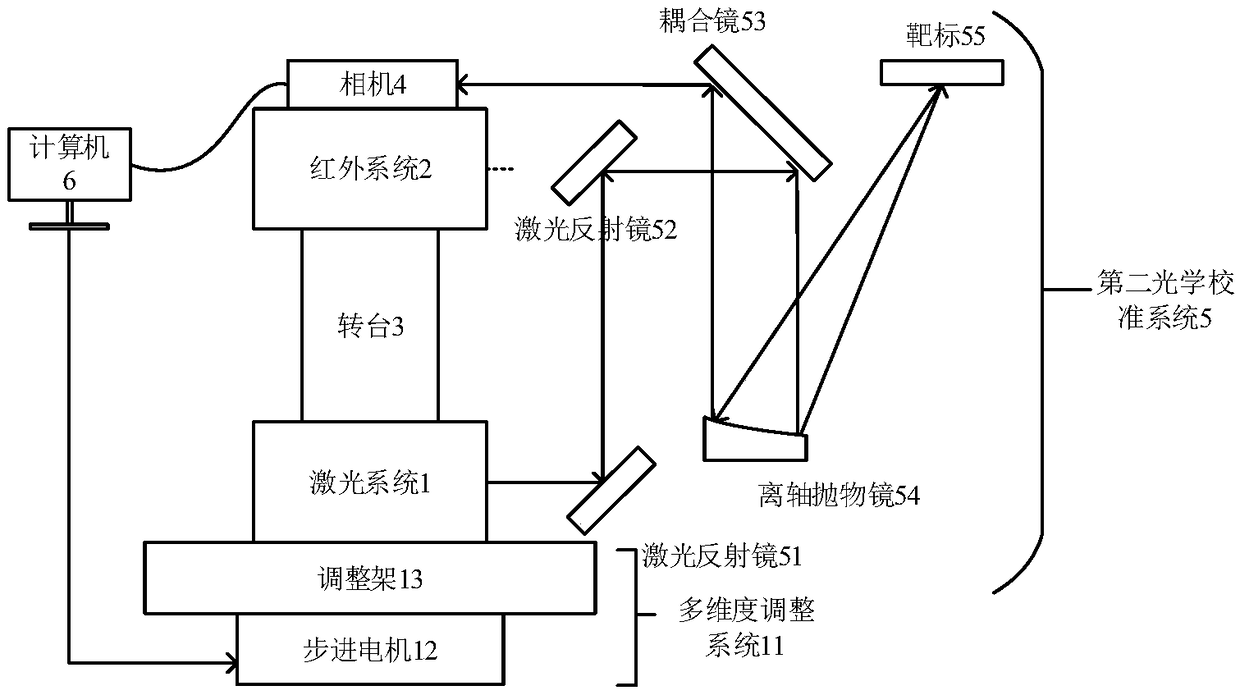

[0027] Such as Figure 1-2 As shown, a multi-optical axis automatic calibration system provided by the embodiment of the present invention includes: a near-infrared laser ranging system 1, which is installed on a multi-dimensional adjustment system 11; an infrared system 2, which communicates with the near-infrared A laser ranging system 1 is connected for determining the position of the target. In practical applications, the infrared laser ranging system 1, the infrared system 2 and the turntable 3 can rotate 360 degrees without stopping, so that the infrared system 2 can find a target within a certain range around, and when a certain target is locked, the near Infrared laser ranging system 1 emits ranging laser beams to measure the actual distance of the target, which requires near-infrared laser ranging system 1 and infrared system 2 to have good coaxiality, otherwise it is difficult to obtain accurate measurement results.

[0028] The imaging system 4, usually using a v...

Embodiment 2

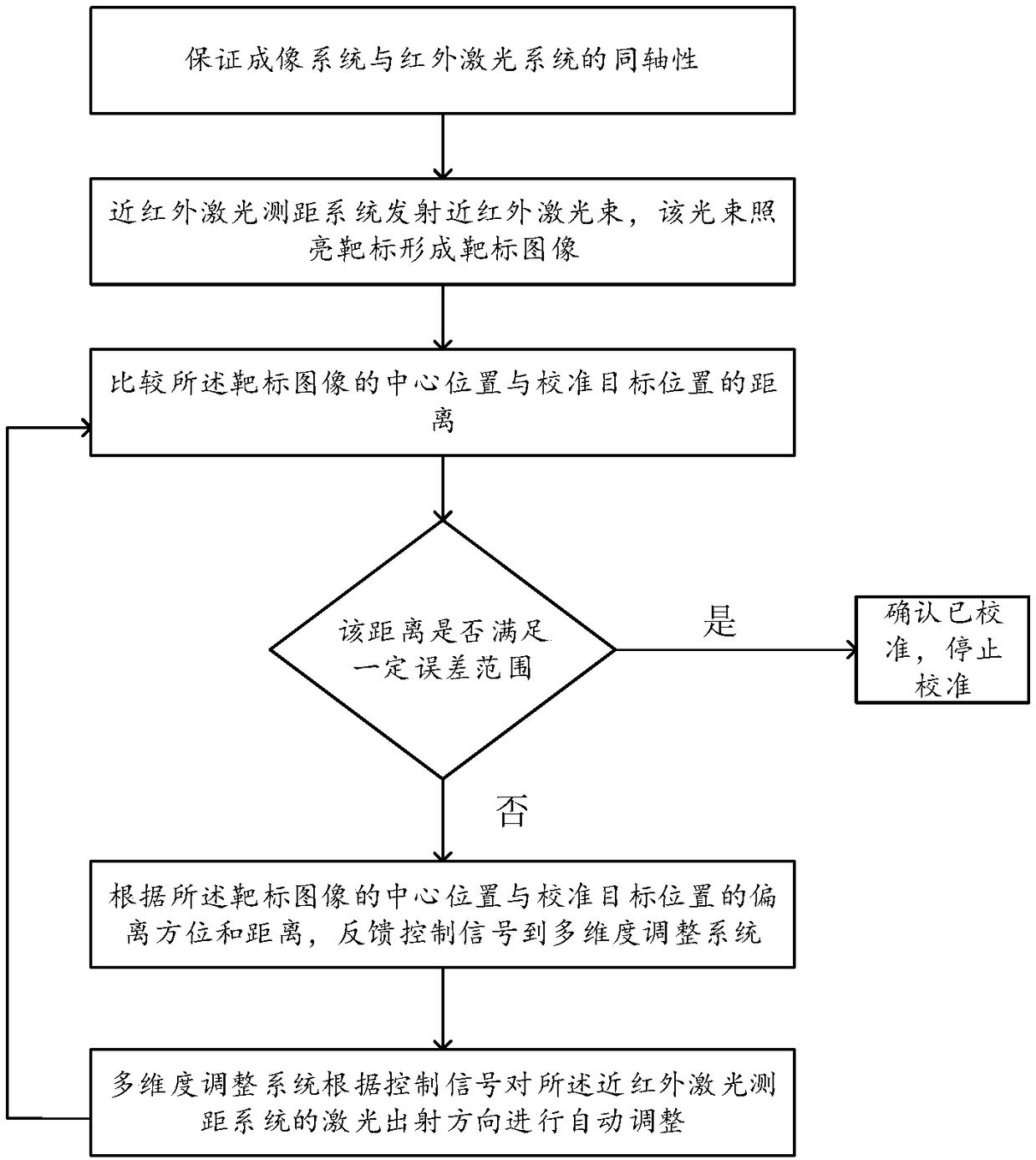

[0036] An embodiment of the present invention provides a multi-optical axis automatic calibration method, including: realizing the coaxiality between the imaging system 4 and the infrared system 2 through the first optical calibration system; the near-infrared laser ranging system 1 emits a near-infrared laser beam, and the beam The target 55 is illuminated after being reflected by the first laser reflector 51, the second laser reflector 52, the coupling reflector 53, and the off-axis parabolic mirror 54 in sequence; the light beam emitted by the illuminated target 55 passes through the off-axis parabola in sequence The mirror 54 and the coupling mirror 53 enter the imaging system 4 to form a target image; the computer system 6 compares the distance between the center position of the target image and the calibration target position; when the distance meets a certain error range, it is confirmed that it has been calibrated; Otherwise, according to the deviation azimuth and dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com