Device and method for testing electrical conductivity of slurry

A technology of conductivity and slurry, which is applied in the field of electrochemistry, can solve the problems of four-probe inability to test the resistivity of slurry materials and repeatedly replace probes, so as to save materials, improve work efficiency, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] 1. Preparation of conductive paste: use the step-by-step method to prepare conductive pastes with different solid contents, and the specific ratios are shown in Table 1:

[0045] Table 1

[0046]

Embodiment 1

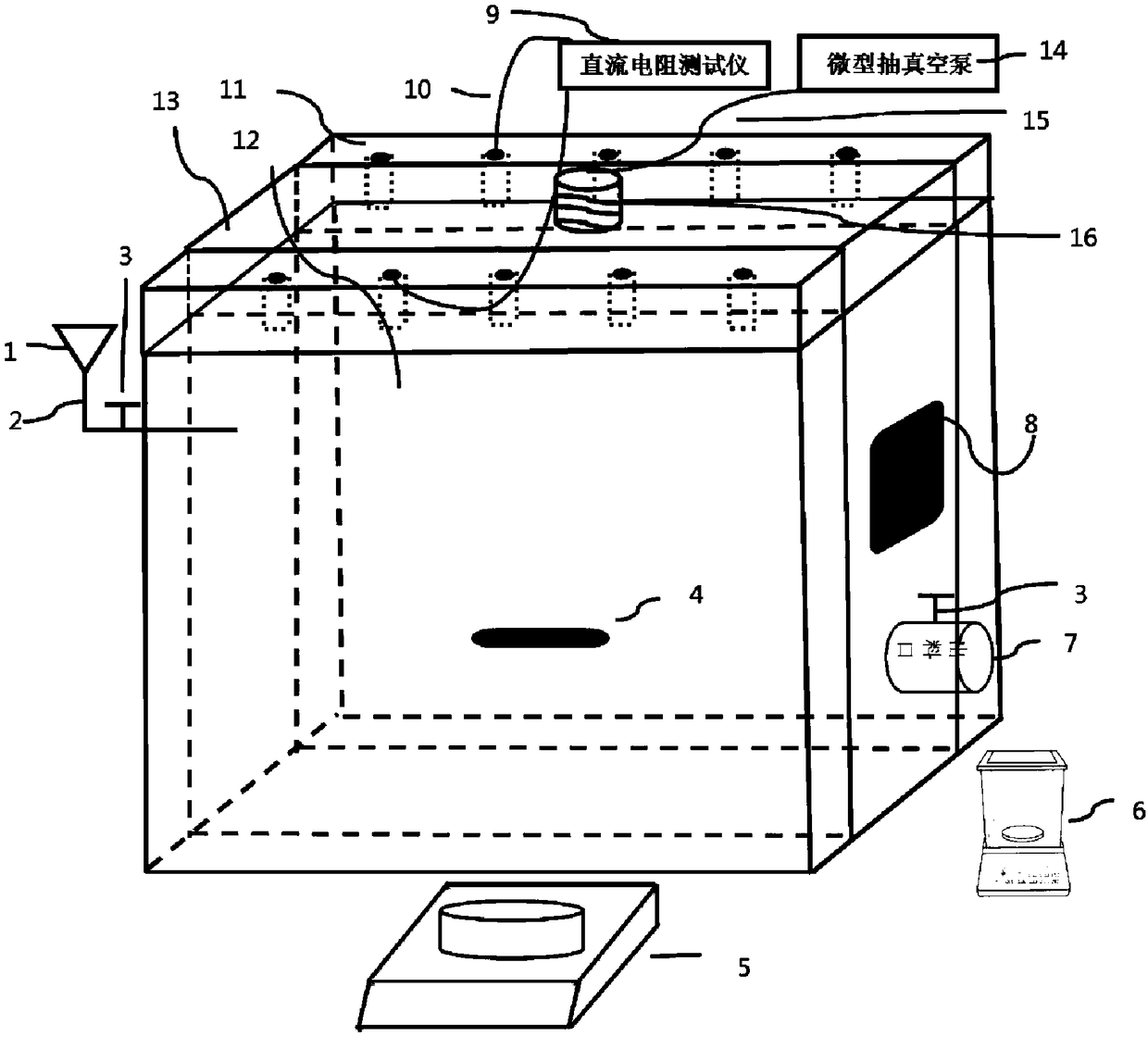

[0048] Will figure 1Open the upper cover 13 of the container, add conventional conductive agent dry powder in the sealed container 12, add the dispersant in the sealed container 12, and add the solvent into the sealed container 12 through the funnel 1 and the DN15 rubber tube 2 (the cross-sectional area of the rubber tube is 0.0177 square decimeters, the flow rate 0.1dm / s, that is, adding 10.62g of solvent deionized water per minute, 13.65min, 5% solid slurry solvent can be added to the sealed container), cover the upper cover, put it on the magnetic stirrer 5, and turn on the magnetic force Stirrer 5, rotating speed 1500rpm / s, stirring rotor 4 promptly stirs the material in the container, stirs for 4h until the slurry is dispersed and mixed evenly, then the stirring can be ended, and the vacuum pump 14 is connected to vacuumize for 20min to remove the air bubbles in the slurry, 5 The preparation of the conductive paste under the % solid content is completed; the solid-conta...

Embodiment 2

[0050] Since the special conductive paste does not know how much to add to achieve the effect of 2% of the conventional conductive paste, it is prepared according to the proportion of Example 1 from high solid content to low solid content to obtain special conductive paste.

[0051] 2. Slurry Conductivity Test

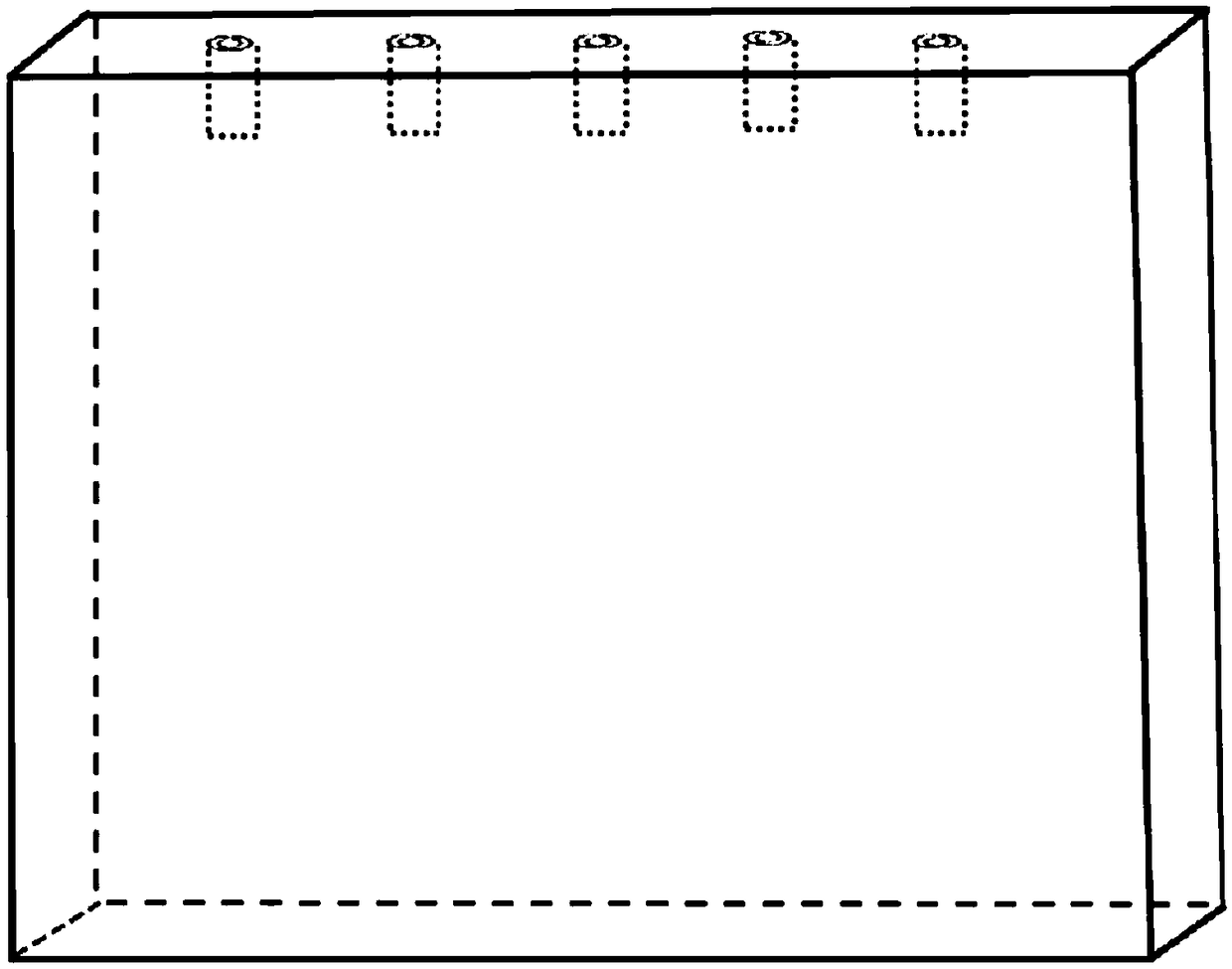

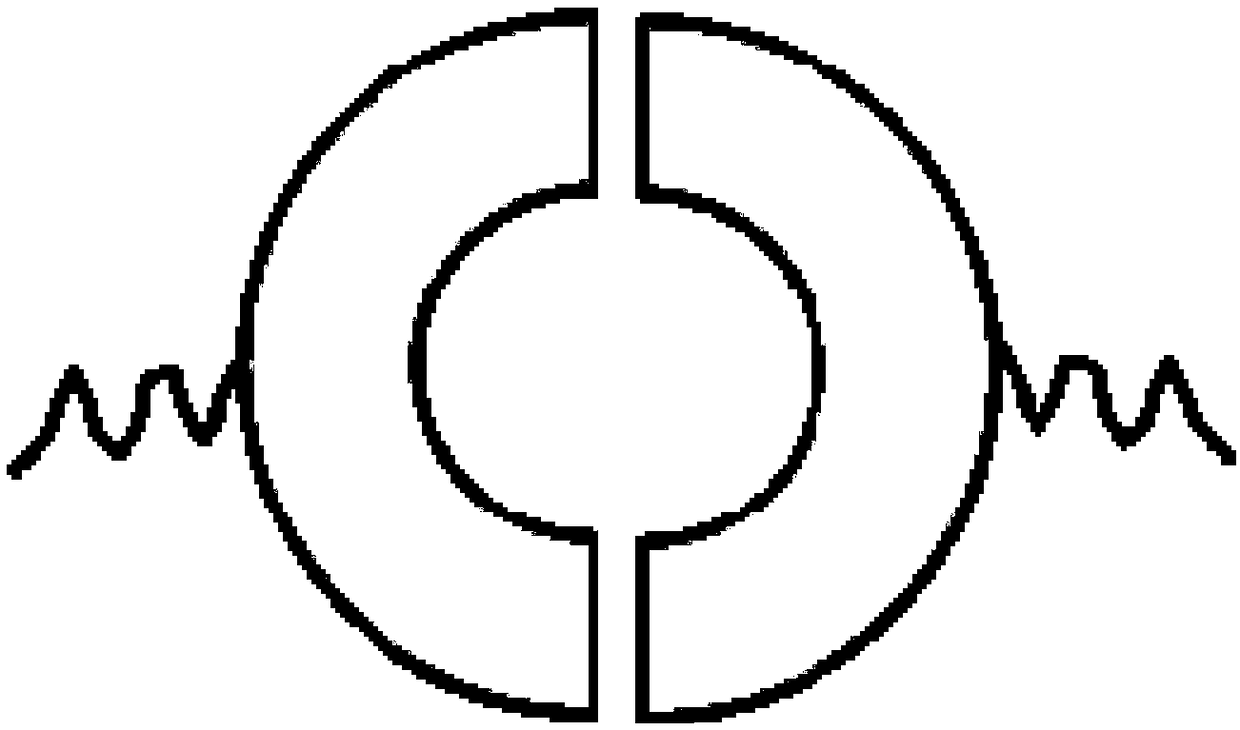

[0052] Combine (1) the slurry that just fills the entire container figure 1 Connect the test device to the test system shown, turn on the DC resistance tester 9, insert the two wires 10 of the DC resistance tester 9 into the double U-shaped contact points, and make the wires smoothly connected to the conductive set under the action of the spring force. At the corresponding concave point of the fluid 11, and the contact is more sufficient, the infrared temperature measuring and controlling instrument 8 is used to test the change of the resistance value of the conductive paste at 25 ± 2 °C in the same time at 5 parallel points with different solid contents. The formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com