A rapid detection method for food deterioration and its detector

A detection method and detector technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as surface wrinkles, large differences in tissue structure, and detection result errors, and achieve fewer influencing factors, high accuracy, and adaptability broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

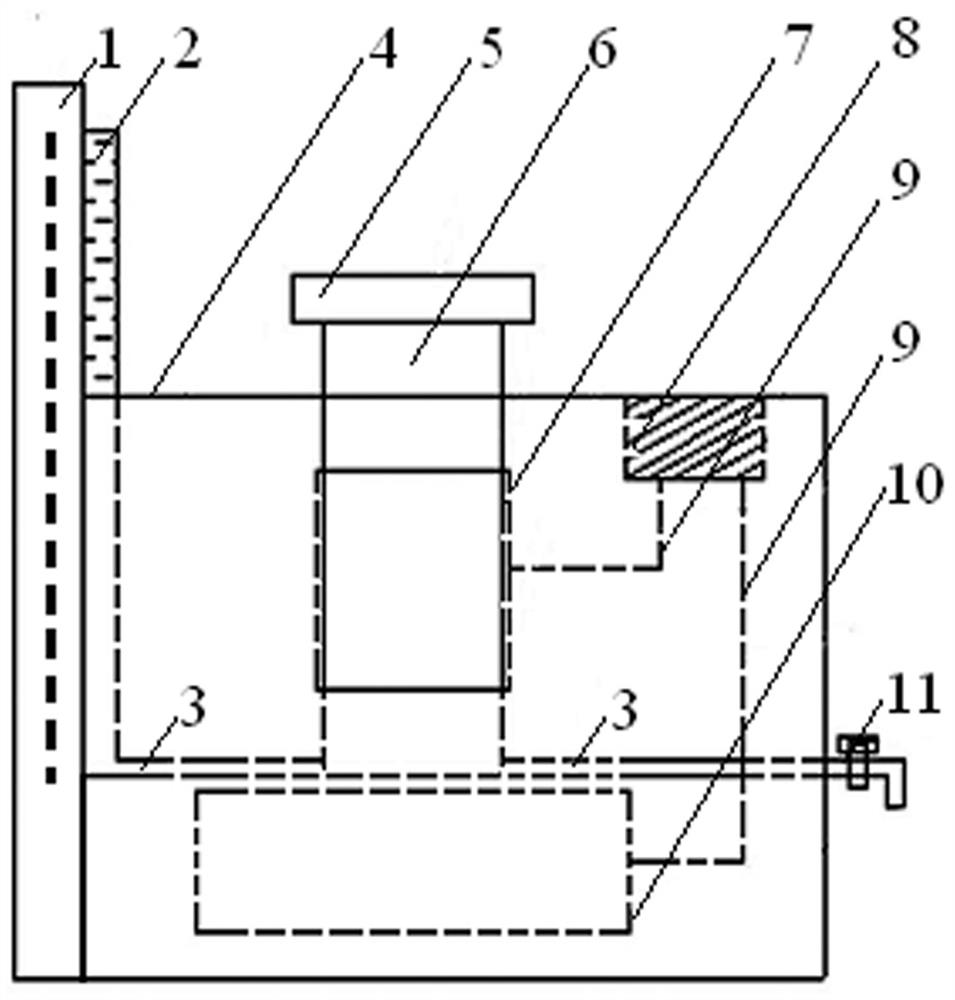

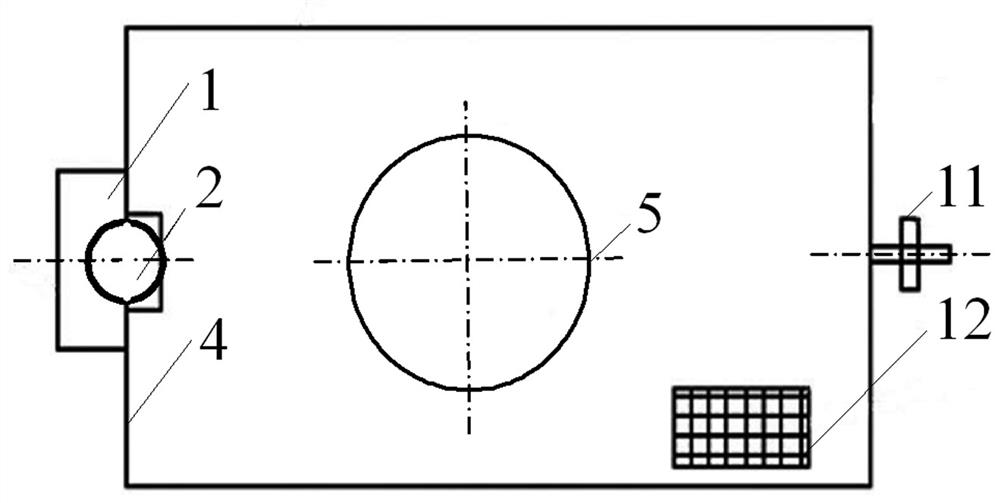

[0028] (a) Take 50g of the wheat sample (1) and put it into the container of the stirring grinder, add 500ml of distilled water, stir at a speed of 300 rpm for 30 seconds without breaking the grain grains, filter out the stirring washing liquid and add Distilled water to 500ml is used as the detection liquid of wheat external mildew condition; The detection liquid is all added in the reaction tank 6 of detector, the temperature of setting constant temperature control element 7 on operation panel 12 is 30 ℃, the stirring speed of magnetic stirrer 10 200 rpm, press the start button to enter the stirring and heating state, when the temperature of the detection solution reaches 30°C, enter the constant temperature state, add 10 ml of hydrogen peroxide solution with a concentration of 30%, tighten the sealing cap 5, and press the The detection button on 12 starts the detection timing, and the instrument emits a warning sound after 5 minutes, and records that the liquid level on the ...

Embodiment 2

[0032] (a) Take 50g of the wheat sample (2) and put it into the container of the stirring grinder, add 500ml of distilled water, stir at a speed of 300 rpm for 30 seconds under the premise of not breaking the grain grains, and filter out the stirring and washing liquid as the wheat External mildew condition detection liquid; add the filtered detection liquid to 500ml with distilled water, all add in the reaction tank 6 of the detector, set the temperature of the constant temperature control element 7 on the operation panel 12 to be 30°C, magnetic stirrer 10 The stirring speed is 200 rpm, press the start button to enter the stirring and heating state, when the temperature of the detection solution reaches 30°C, it enters the constant temperature state, add 10 ml of hydrogen peroxide solution with a concentration of 30%, and tighten the sealing cap 5, Press the detection key on the operation panel 12 to start detection and timing. After 5 minutes, the instrument emits a warning s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com