Micro-fluidic chip signal denoising method based on double threshold of energy element

A microfluidic chip, threshold denoising technology, applied in pattern recognition in signals, instrument, character and pattern recognition, etc., can solve problems affecting signal accuracy, Gibbs phenomenon, easy loss of signal high-frequency information, etc. Achieve the effects of effectively removing noise, suppressing pseudo-Gibbs phenomenon, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

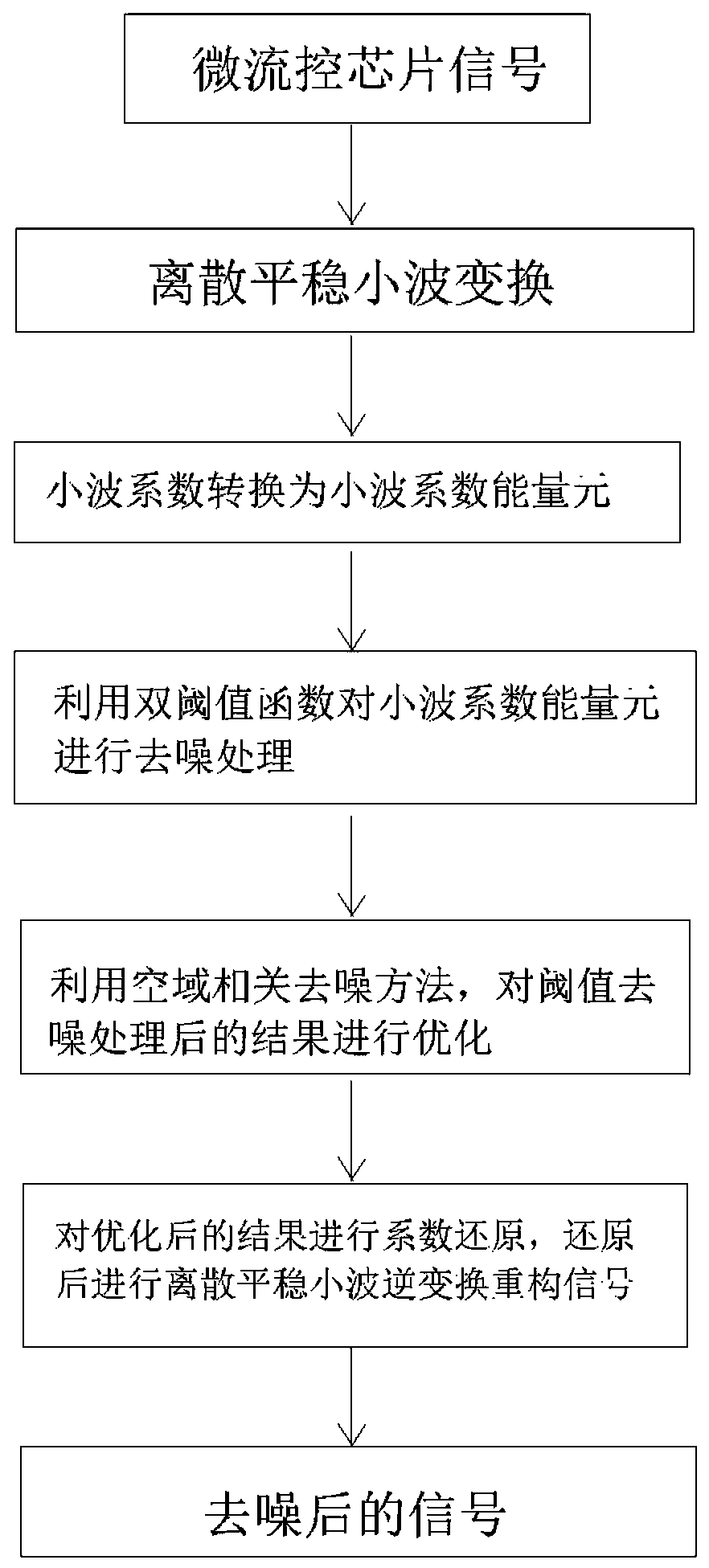

[0054] like figure 1 As shown, a microfluidic chip signal denoising method based on energy element double threshold, including the following steps:

[0055] 1. First, according to the characteristics of the actually collected microfluidic chip signal and the denoising effect of the simulated microfluidic chip signal, the wavelet base and decomposition level are selected, and the discrete stationary wavelet transform is performed to obtain the wavelet coefficients.

[0056] 2. Convert wavelet coefficients to wavelet coefficient energy elements, including the following steps:

[0057] (1) Perform amplitude stretching processing on the wavelet coefficients after wavelet transformation. Before each wavelet coefficient is converted into wavelet coefficient energy elements, the wavelet coefficients need to be subjected to amplitude stretching processing to meet the premise of energy element conversion. The mathematical formula for amplitude stretching of wavelet coefficients is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com