Method for coating support agents with modified reactive resin compositions, coated support means and use of the coated support means in fracking-conveying methods

A technology of resin composition and proppant, applied in the field of hydraulic fracturing, can solve the problems of high cost of use and difficult to control product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

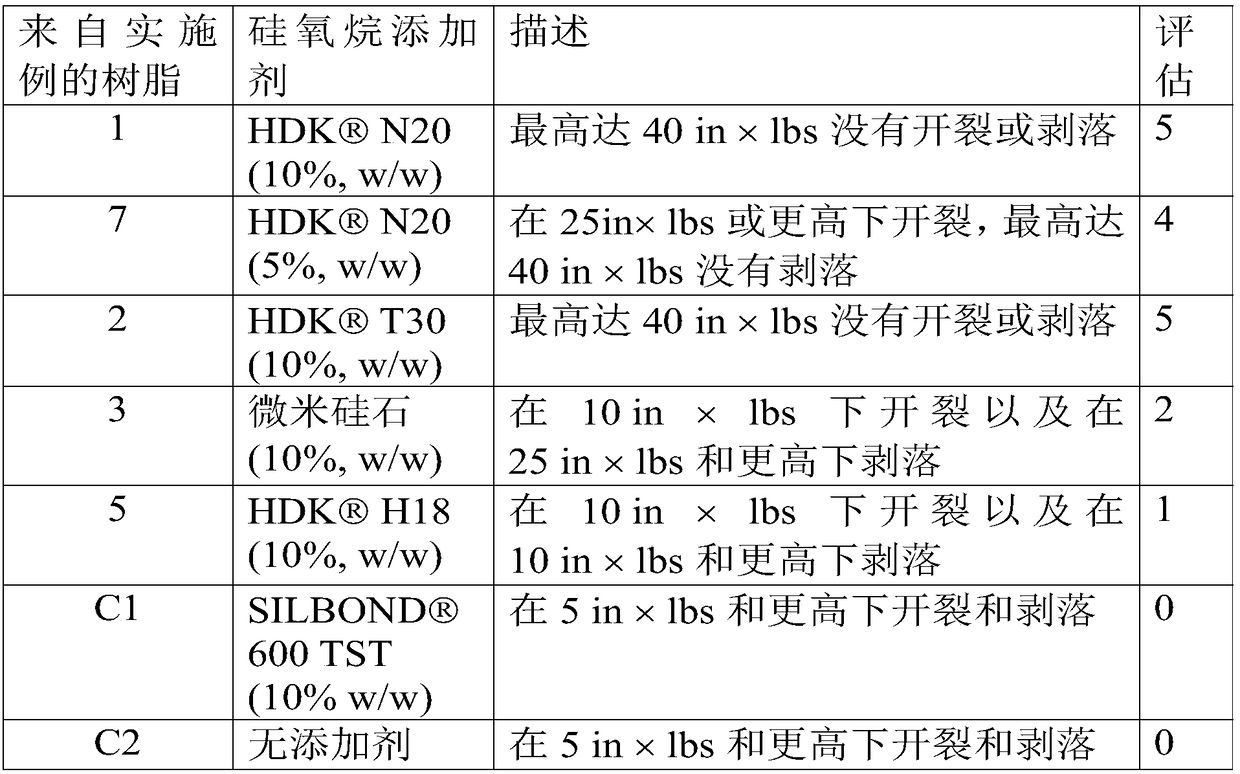

Examples

Embodiment 1

[0089] In a MOLTENI LABMAX with a stripper and dissolver tray, 450 g novolac "Resin 14772" (Plastics Engineering Company, Sheboygan, USA) was heated to 130°C and melted, during which time nitrogen was passed through the resin.

[0090] When all the resin is melted, stirring is performed for about 10 minutes at a container impact of 10 rpm and a dissolver speed of about 500 rpm. Then add 50g N20 (with 170-230m 2 / g of hydrophilic silica with a BET surface area; available from Wacker Chemie AG) was added in batches (small spoons, volume about 50-100 mL) and stirred at 500 rpm for about 2 minutes in each case. When all the HDK has been added, increase the speed of the dissolver to 4500 rpm, and then continue to stir for 10 minutes. While still hot, the material is then poured onto the PTFE membrane and mechanically stirred. The temperature after homogenization was 165°C. Cooling produces a caramel-colored odorless solid.

Embodiment 2

[0092] Using the method of Example 1, 50g of T30 (with 270-330m 2 / g of BET surface area hydrophilic silica; available from Wacker Chemie AG, Munich, Germany) was added and mechanically stirred. The temperature after homogenization was 171°C. Cooling produces a caramel-colored odorless solid.

Embodiment 3

[0094] Using the method of Example 1, 50g of micron silica (with 25-60m 2 / g of BET surface area hydrophilic silica) was added and mechanically stirred. The temperature after homogenization was 171°C. Cooling produces a caramel-colored odorless solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com