Exhaust after-treatment system

An exhaust duct and gas technology, applied in exhaust treatment, exhaust devices, separation methods, etc., can solve problems such as reducing machine fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

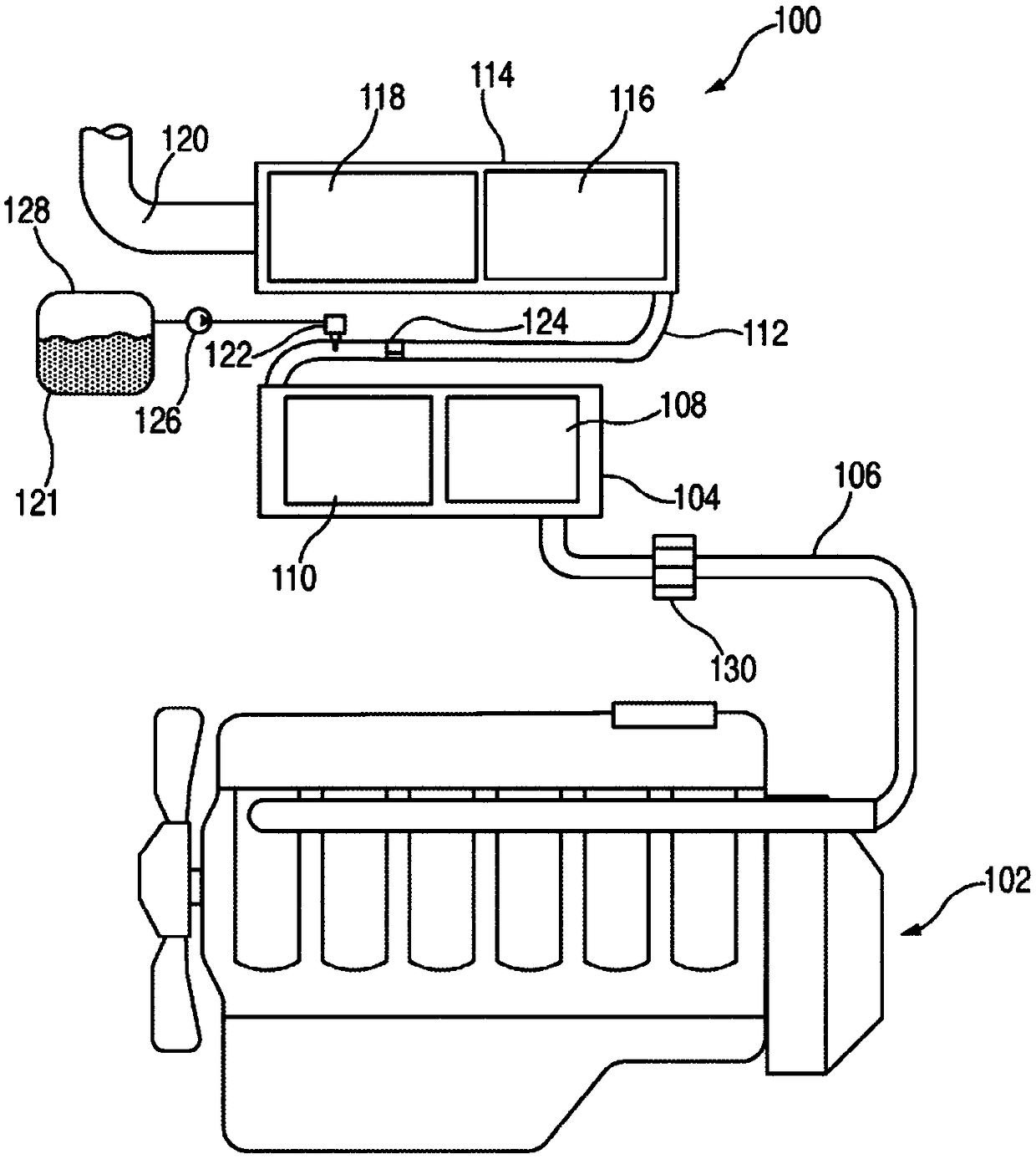

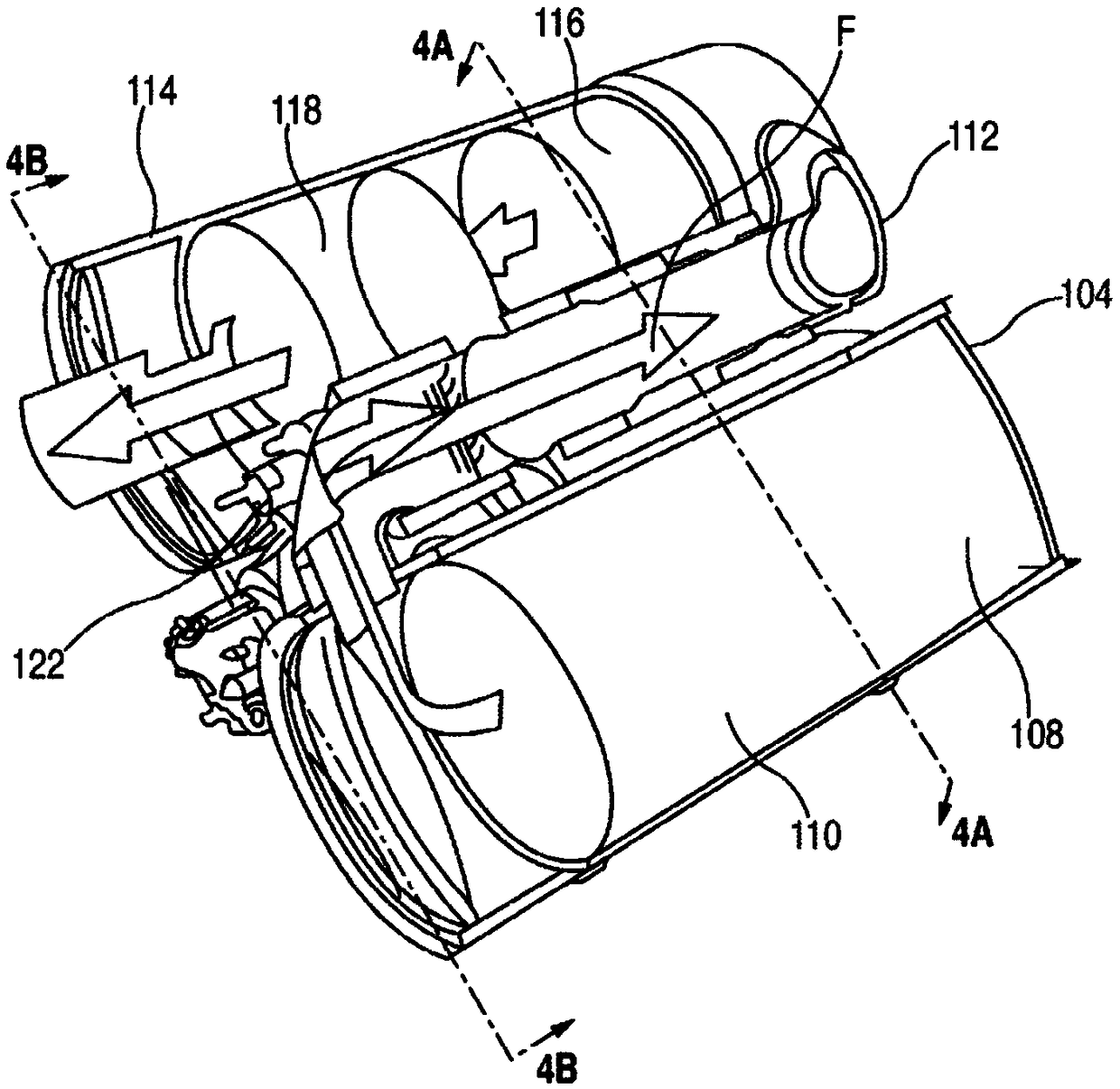

[0011] 1 and 2 are representations of an exhaust aftertreatment system 100 known in the art. In the illustrated embodiment, system 100 includes a first module 104 fluidly connected to an exhaust conduit 106 of engine 102 . During engine operation, the first module 104 is arranged to internally receive engine exhaust from the conduit 106 . The first module 104 contains a diesel oxidation catalyst (DOC) 108 arranged in series upstream of a diesel particulate filter (DPF) 110 , each of which has a relatively large frame. It should be noted that CDPF 110 is a coated DPF (CDPF). Exhaust gas provided by the engine 102 to the first module 104 first passes through the DOC 108 , then through the CDPF 110 , and then into the transfer conduit 112 .

[0012] A transfer conduit 112 fluidly interconnects the first module 104 with the second module 114 such that exhaust gases from the engine 102 may pass through the first module 104 and the second module 114 in series before being released...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com