Optical fiber structures and methods for varying laser beam profile

A laser beam and optical fiber technology, applied in the field of laser systems, can solve the problems of damage, expensive and time-consuming fragile optical components of laser systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

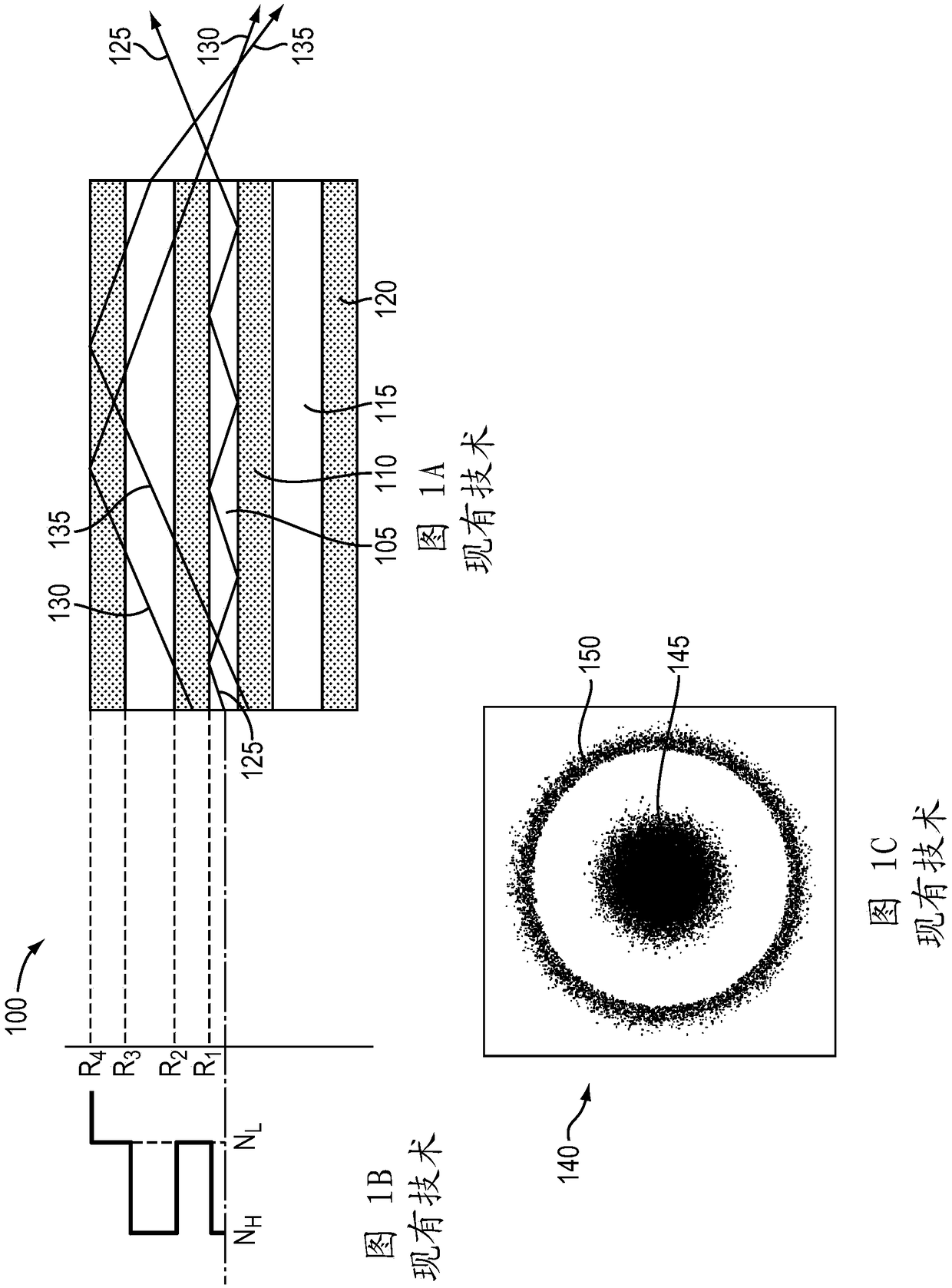

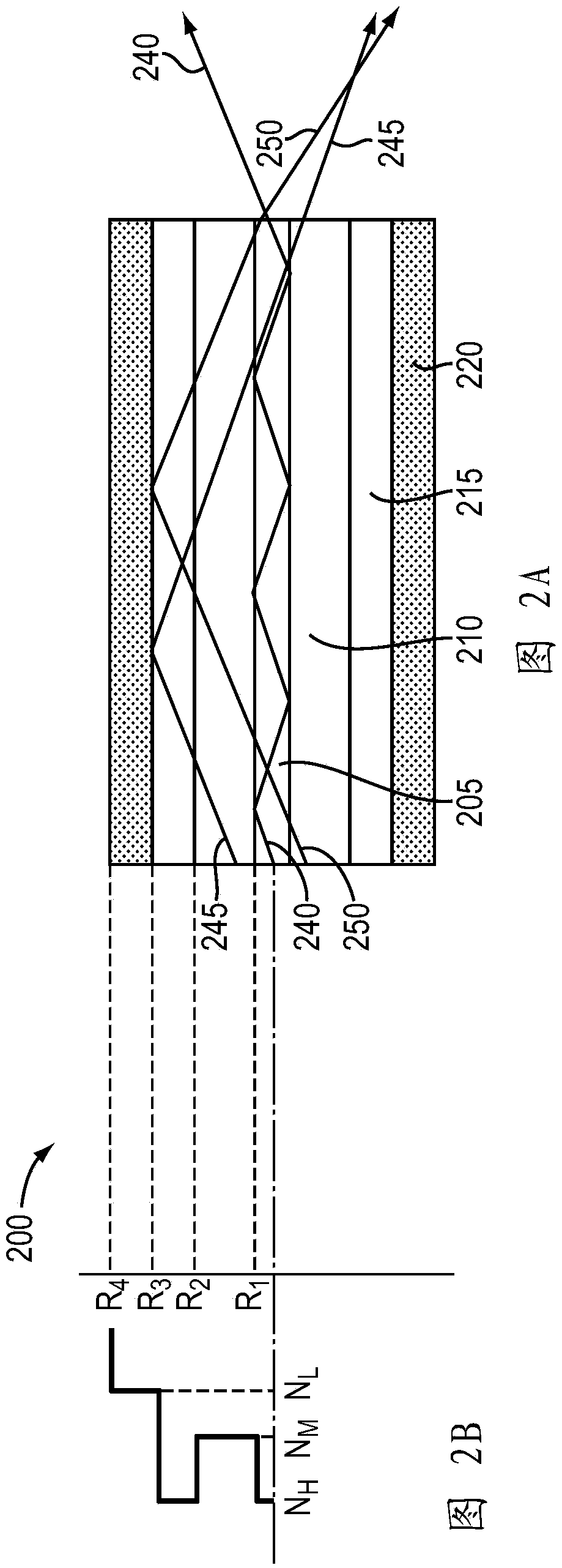

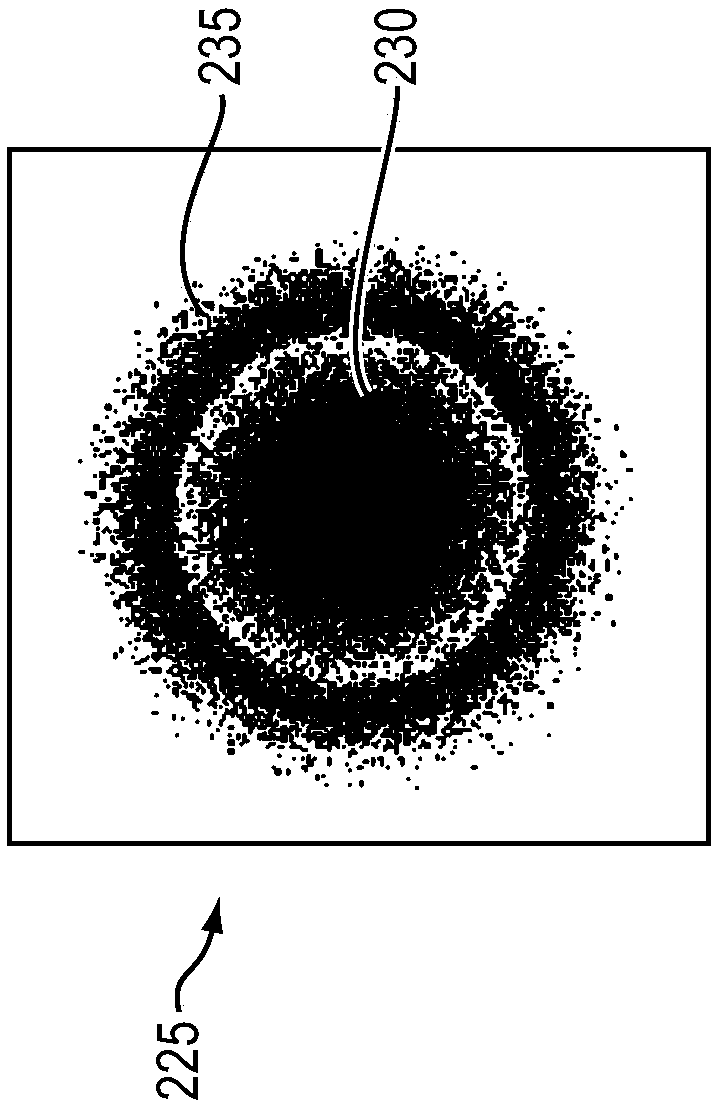

[0034] Figure 1A A conventional double clad fiber 100 is shown having a central core 105 , an inner cladding 110 , a ring core 115 and an outer cladding 120 . The radius of each layer (core or cladding) of fiber 100 is given by R 1 , R 2 , R 3 or R 4 means, such as Figure 1B shown. In a conventional double-clad fiber 100, the two cores 105, 115 typically have the same higher refractive index N H , and the two cladding layers 110, 120 generally have the same lower refractive index N L ,Such as Figure 1BAs shown, therefore, the two cores 105, 115 have the same NA: sqrt(N H 2 -N L 2 ).

[0035] Figure 1A The transmission of three representative rays in fiber 100 is also depicted. Light ray 125 is coupled into central core 105 , is confined by central core 105 , and exits central core 105 at the same angle as it entered central core 105 . Rays 130 and 135 are transmitted into inner cladding 110 , propagate throughout the fiber region, and are confined by outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com