Circuit board, semiconductor device, image capturing device, solid-state image capturing element, method of manufacturing solid-state image capturing element, and electronic instrument

一种固态图像、状态的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决滤色器涂层不均匀等问题,达到减少涂布不均匀、抑制产量的降低、抑制特性的降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

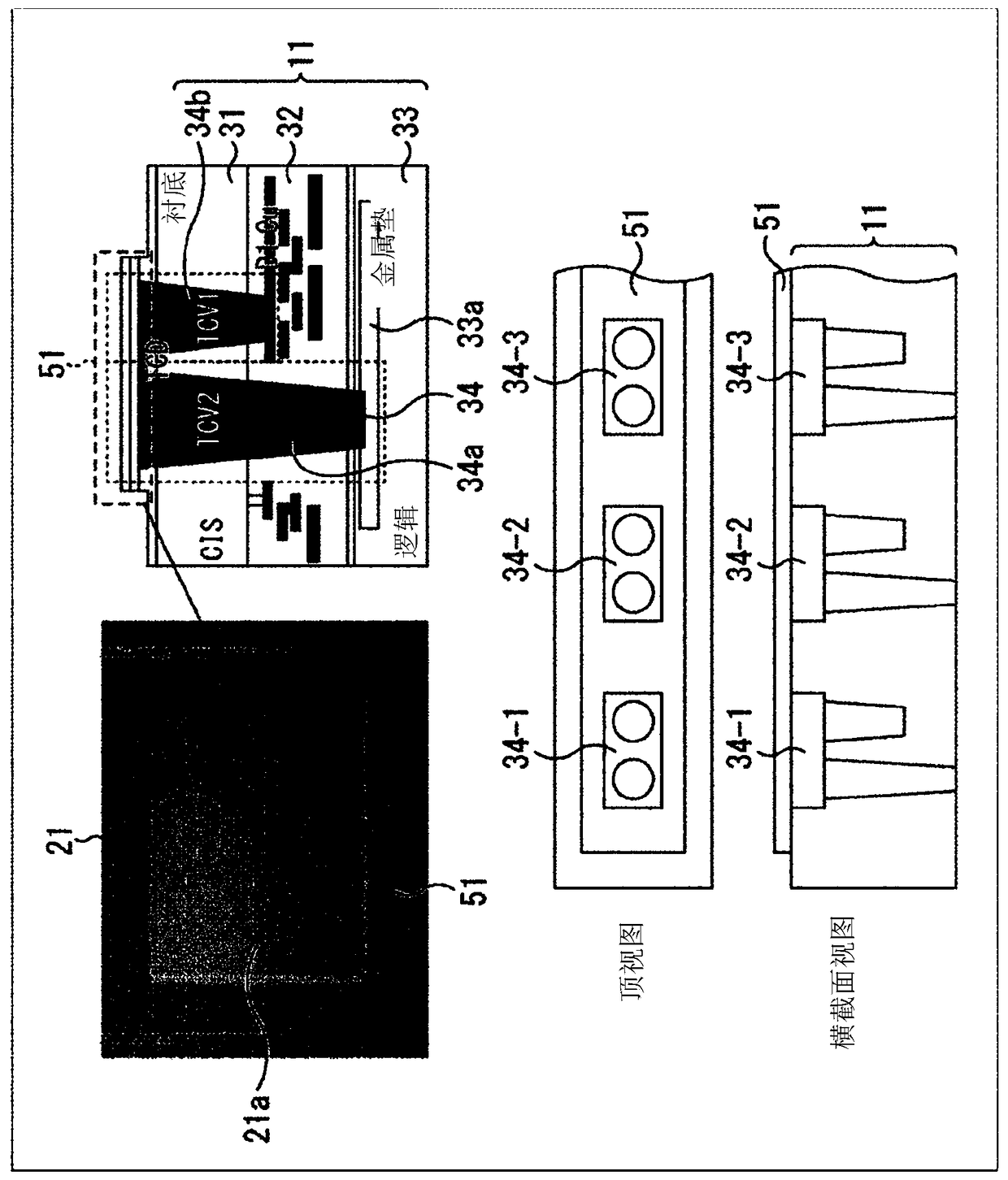

[0054] Hereinafter, preferred embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. It should be noted that, in this specification and the drawings, constituent elements that have substantially the same functional configuration will be denoted by the same reference numerals, and repeated description thereof will be omitted.

[0055]

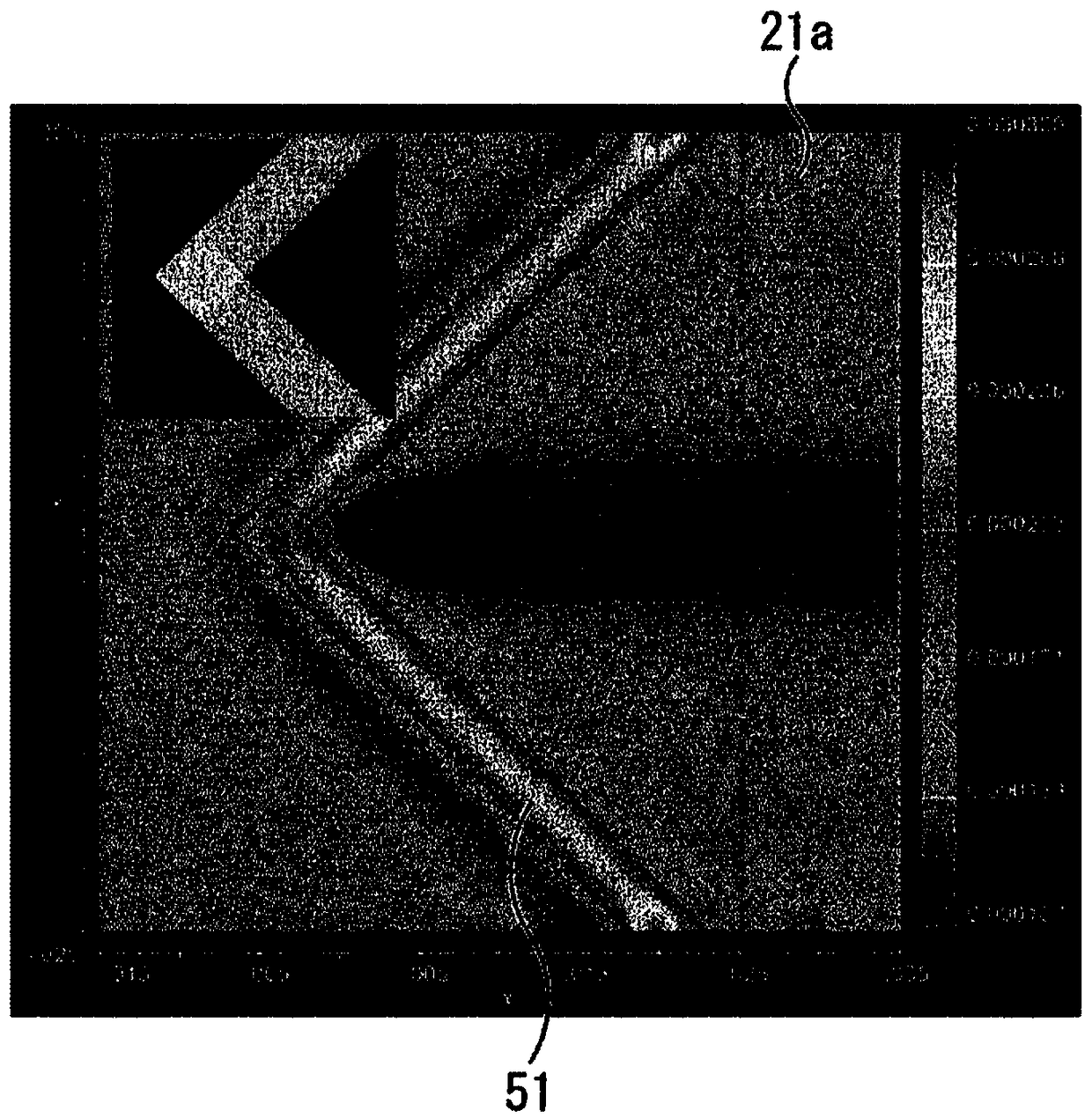

[0056] In describing the configuration of the solid-state image sensor to which the technology of the present disclosure is applied, first, the mechanism by which the above-mentioned coating unevenness of the photoresist occurs will be described.

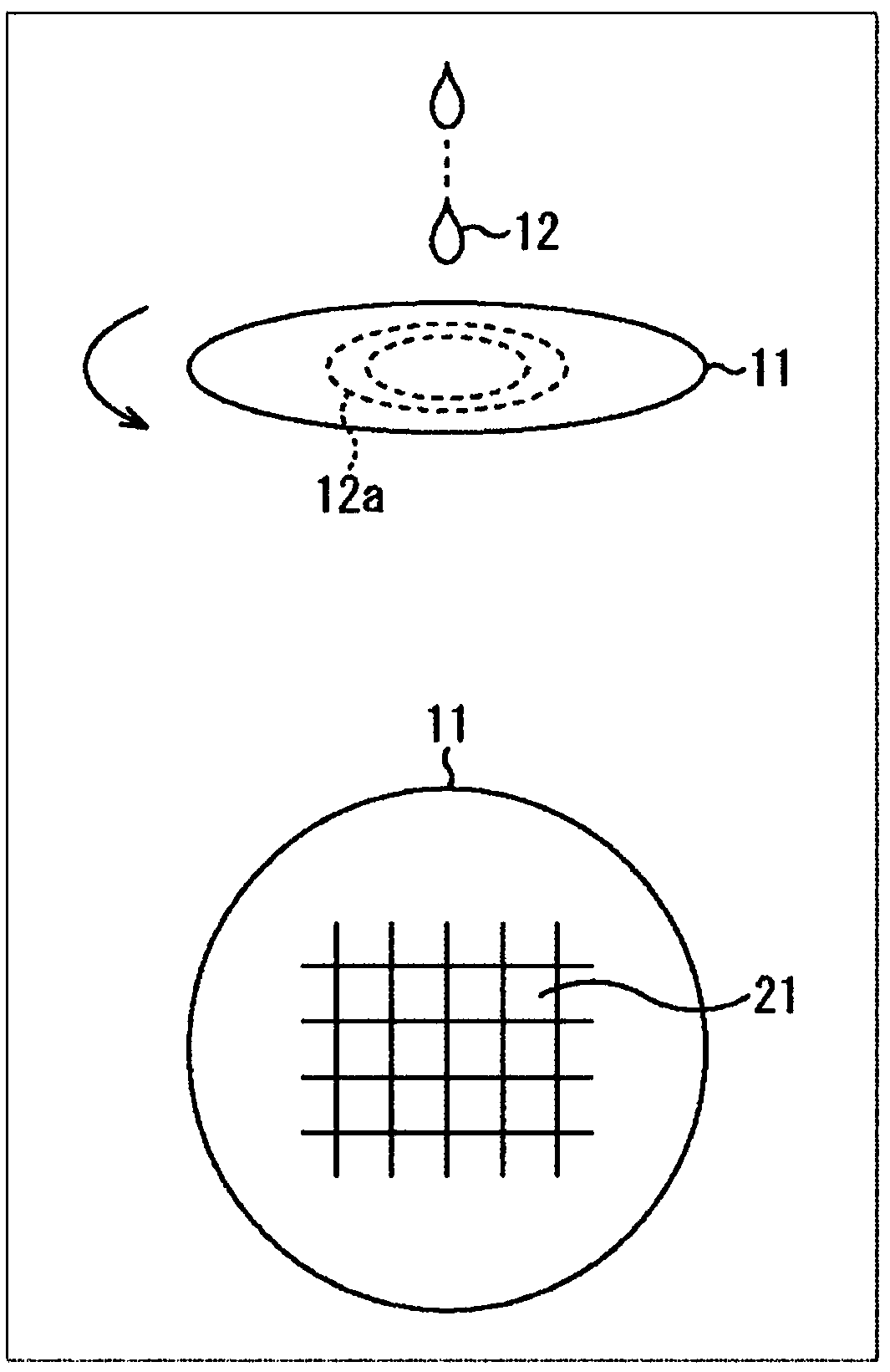

[0057] Coating unevenness of photoresist occurs in the photolithography process.

[0058] The photolithography process is a process for forming a pattern in which a photoresist layer is formed on a wafer containing a large number of solid-state image sensors before dicing, and the photoresist layer corresponding to the pattern is exposed by expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com