A low frequency pulse vibration generator

A vibration generator and low-frequency pulse technology, applied in the field of oscillators, can solve the problems of limited application occasions, narrow adjustment range of oscillation frequency, high ultrasonic oscillation frequency, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

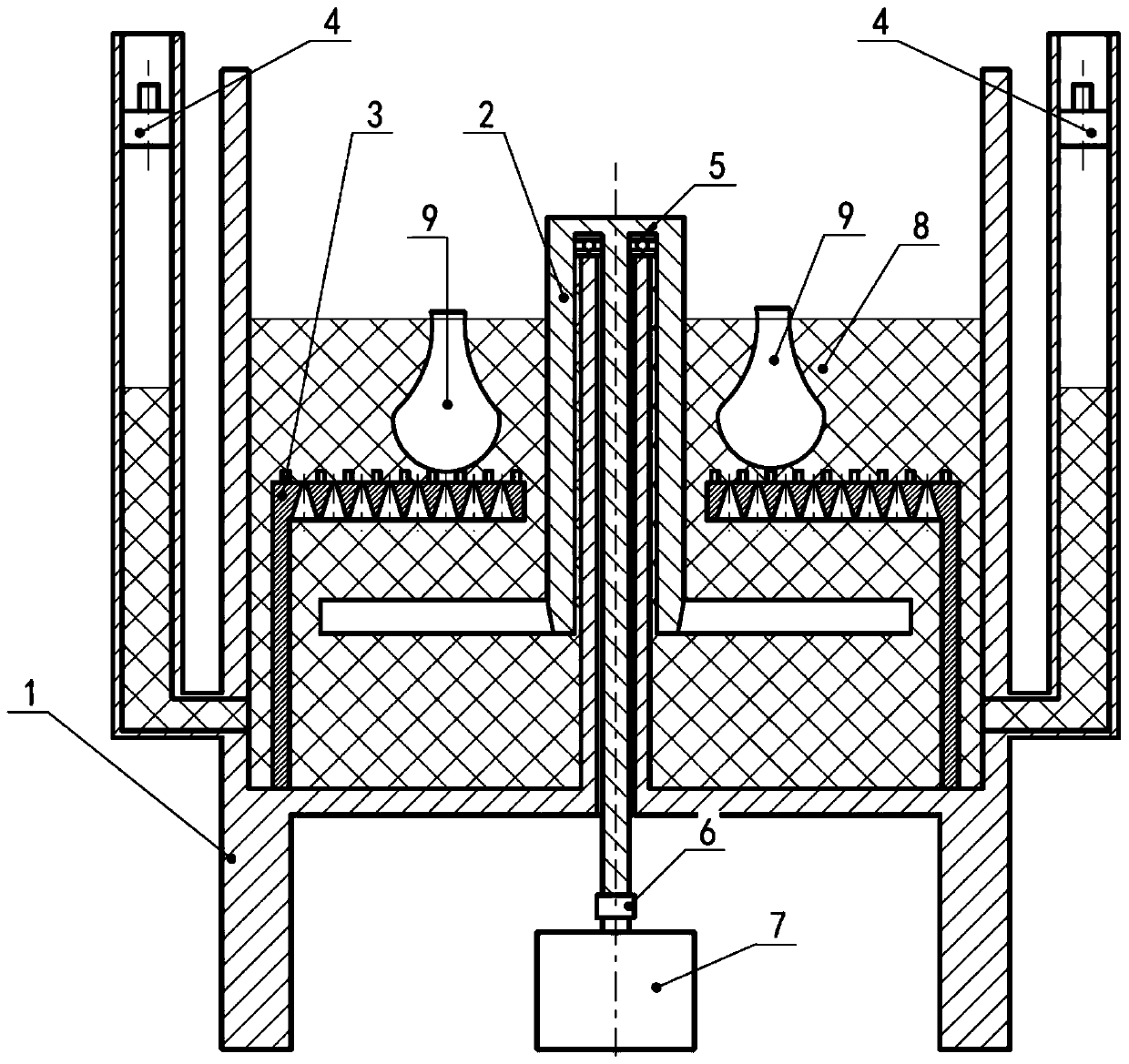

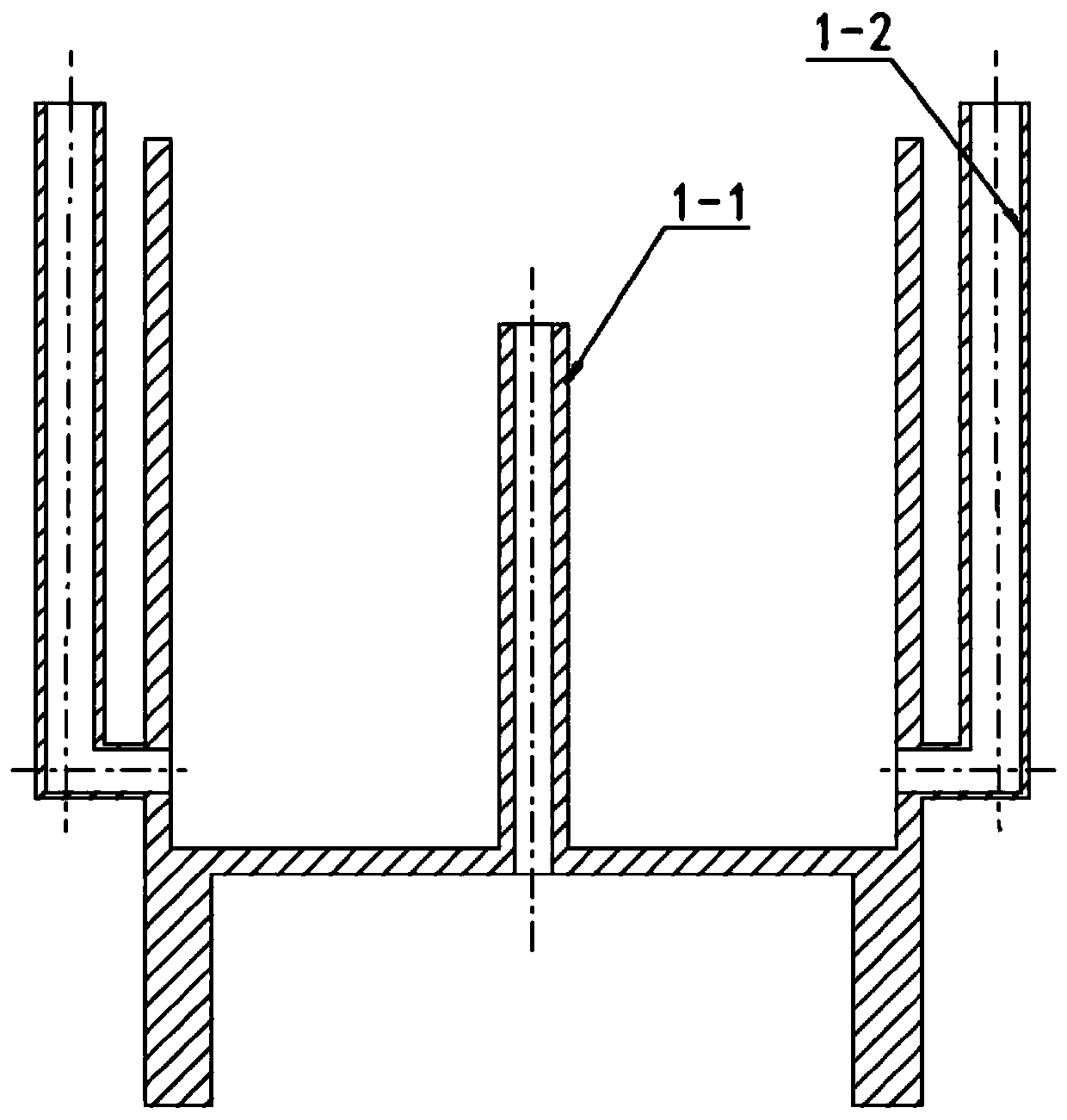

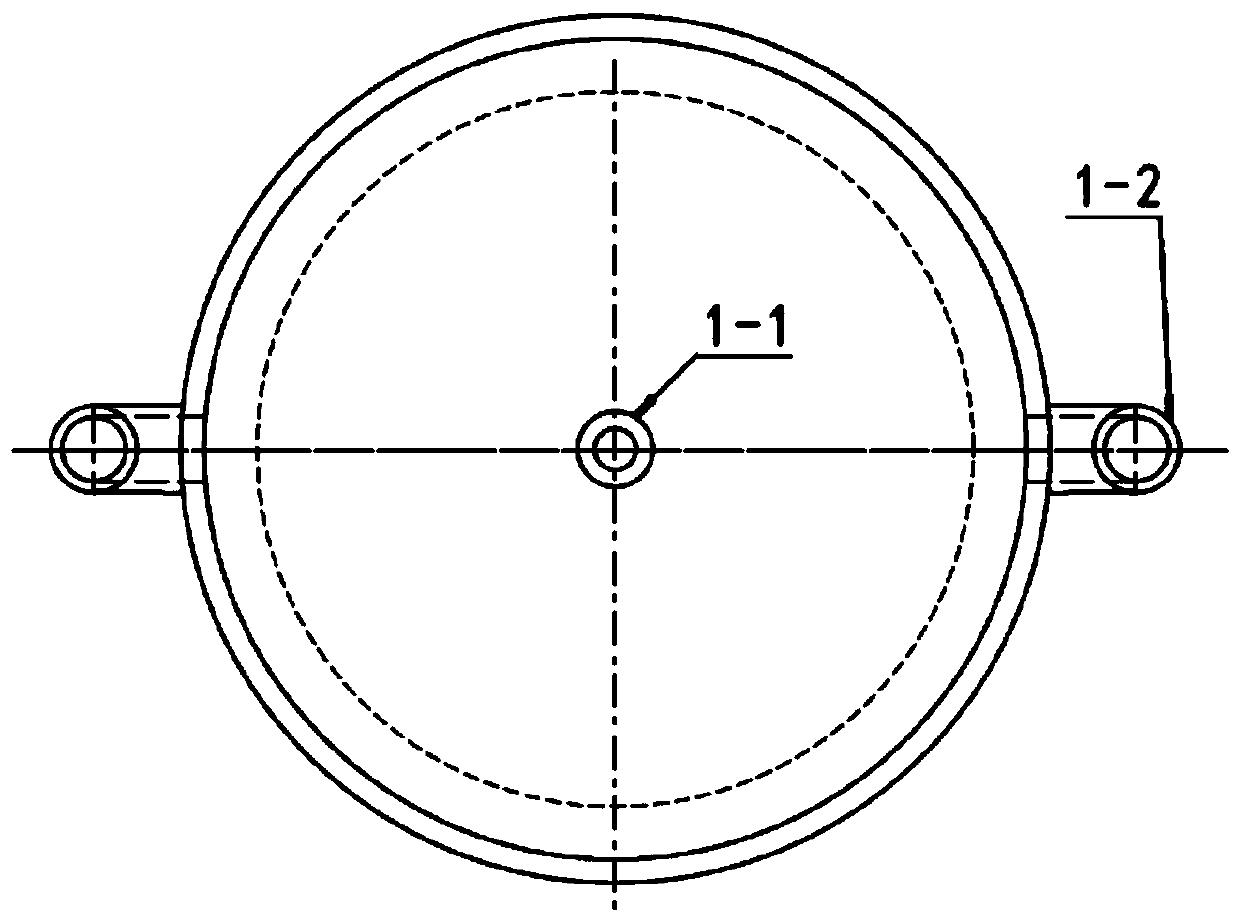

[0020] exist figure 1 , figure 2 and image 3 In the schematic diagram of the low-frequency pulse vibration generator shown, the bottom of the oscillator cavity 1 is connected to the supporting legs, the liquid 8 is filled in the oscillator cavity, and the gas booster chambers 1-2 are arranged on opposite sides of the oscillator cavity. The gas pressurization chamber is higher than the oscillator chamber and connected with it, and the gas pressurization chamber is equipped with a pressing block 4 to increase the pressure above the liquid in the pressurization chamber, and the propeller frame 1-1 is arranged in the oscillator chamber The center of the body, one end of which is connected to the oscillator cavity, and the other end is connected to the rotary paddle 2, the liquid level in the oscillator cavity is lower than the propeller frame, and the bubble destruction frame 3 is located on the outside of the oscillator cavity;

[0021] Such as Figure 4 , Figure 5 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com