Reconstituted bamboo board and preparation method thereof

A technology for recombining bamboo boards and bamboo materials, which is applied in the direction of manufacturing tools, mechanical equipment, wood processing utensils, etc., can solve the problem that the alternative method of adhesive selection has not been paid attention to, and achieve good corrosion resistance, high early strength, and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

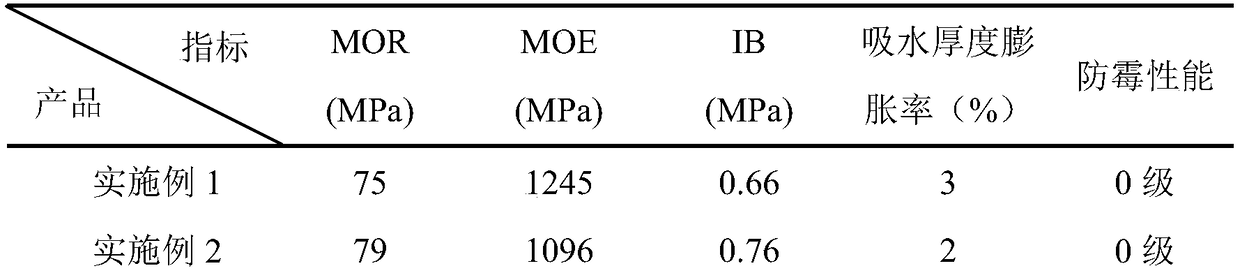

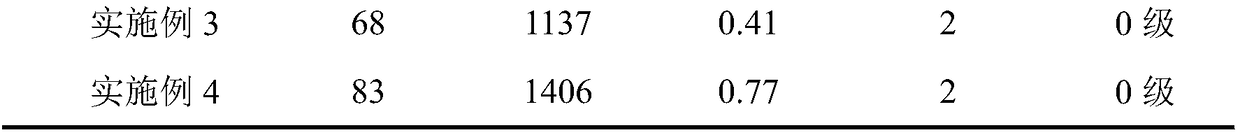

[0065] Example 1

[0066] 1) Bamboo unit preparation

[0067] Cut the moso bamboo into bamboo tubes, cut out bamboo bundles with a length of 350mm (according to the size of the existing moulding equipment) after disintegration; then dry the bamboo bundles, where the drying temperature is (105±5)℃, and the moisture content is 8% (usually 5%-40%) of dry bamboo bundle units.

[0068] 2) Preparation of inorganic adhesive

[0069] 2-1) First, prepare an alkaline excitation solution, blend liquid sodium silicate with a modulus of 1.5 (usually 1-3.5) and a NaOH solution with a concentration of 10 mol / L (usually 1-30 mol / L) to prepare After the mixed solution is cooled to room temperature, let it stand for 20h (usually 20-36h) to make an alkaline excitation solution, standby, liquid Na 2 SiO 3 The volume ratio with NaOH solution is 2.5:1 (usually 1-5:1);

[0070] In the embodiment of the present invention, the NaOH solution is taken as an example as an alkaline solution and mixed with liquid ...

Example Embodiment

[0083] Example 2

[0084] 1) Bamboo unit preparation

[0085] Saw the moso bamboo into bamboo tubes, cut out bamboo filaments with a length of 350mm (according to the size of the existing molding tool) after disintegration; then dry the bamboo filaments, where the drying temperature is (105±5)℃, and the moisture content is 10% (usually 5%-40%) of dry bamboo silk units.

[0086] 2) Preparation of inorganic adhesive

[0087] 2-1) First, prepare an alkaline excitation solution, blend liquid sodium silicate with a modulus of 1.4 (usually 1-3.5) and a NaOH solution with a concentration of 11mol / L (usually 1-30mol / L) to prepare After the mixture is cooled to room temperature, let it stand for 24h (usually 20-36h) to make an alkaline excitation solution, standby, liquid Na 2 SiO 3 The volume ratio to NaOH solution is 2.6:1 (usually 1-5:1);

[0088] 2-2) Put metakaolin and alkali activator in a cement mortar mixer, mix well, then add 6% modifier ethylene-vinyl acetate copolymer hot melt adhes...

Example Embodiment

[0098] Example 3

[0099] 1) Bamboo unit preparation

[0100] Cut the moso bamboo into bamboo tubes, cut bamboo strips with a length of 350mm after disintegration; then dry the bamboo strips, where the drying temperature is (105±5)℃, and the moisture content of the dried product is 8% (usually 5%- 40%) of the dry bamboo strip unit.

[0101] 2) Preparation of inorganic adhesive

[0102] 2-1) First, prepare an alkaline excitation solution, blend liquid sodium silicate with a modulus of 1.3 (usually 1-3.5) and a NaOH solution with a concentration of 20mol / L (usually 1-30mol / L) to prepare After the mixed solution is cooled to room temperature, let it stand for 28h (usually 20-36h) to make an alkaline excitation solution, standby, liquid Na 2 SiO 3 The volume ratio with NaOH solution is 3:1 (usually 1-5:1);

[0103] 2-2) Put metakaolin and alkali activator in a cement mortar mixer, mix well, then add 8% modifier acrylic 707 emulsion, and then perform high-speed shearing and stirring at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com