Preparation of Hydrophobic Double-MOF-Based Porous Carbon Materials

A hydrophobic, MOF-5 technology, applied in the preparation/purification of carbon, carbon compounds, inorganic chemistry, etc., can solve problems such as complex steps, achieve strong adsorption force, rich micropore and mesopore structure, good hydrophobicity water-based effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

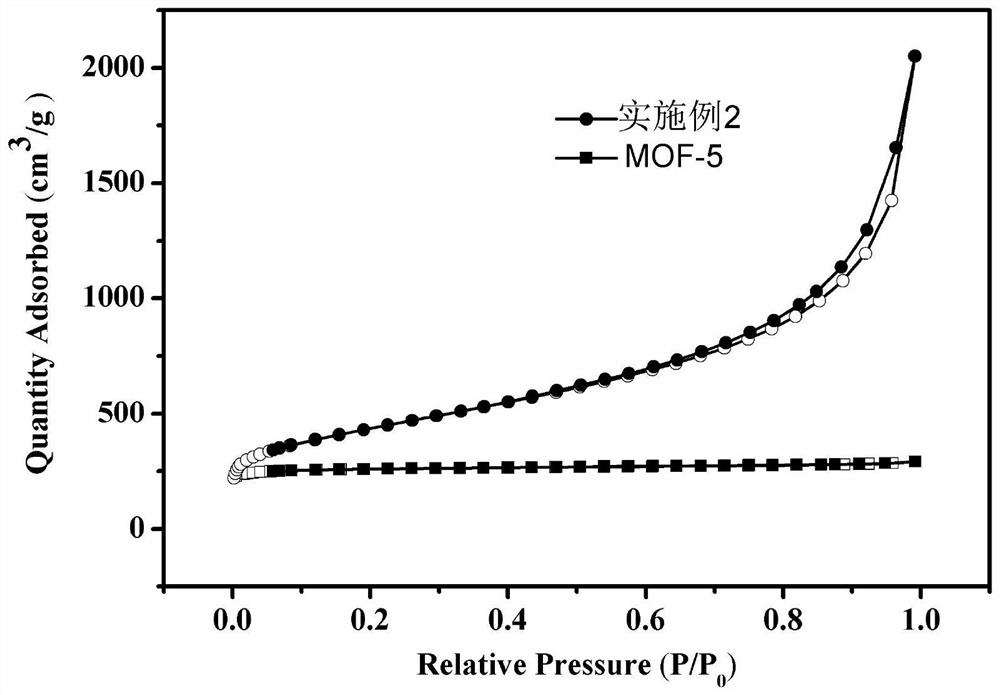

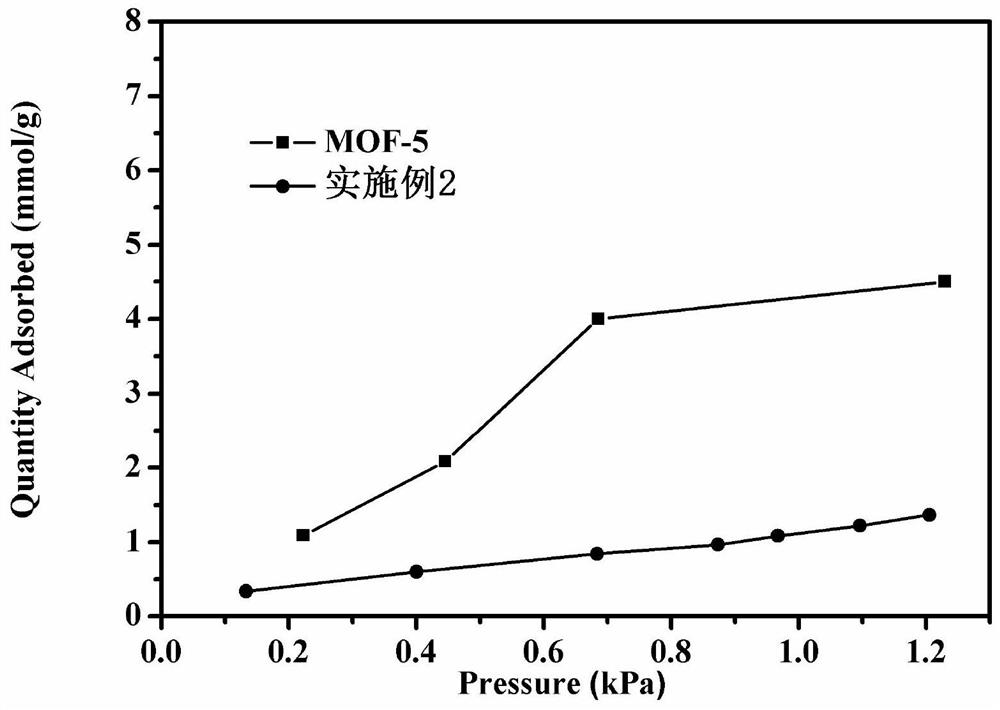

[0026] In order to facilitate comparison and description of the effect of the synthetic method of the hydrophobic double MOF-based porous carbon material of the present invention, Example 1 provides a MOF-5 material prepared according to a conventional method, and the specific preparation method is as follows:

[0027] 9.88g Zn(OAC) 2 2H 2 O and 2.49g terephthalic acid (H 2 BDC) was dissolved in 350 mL of dimethylformamide (DMF), stirred at room temperature for 5 h to obtain the reaction product; the reaction product was centrifuged, washed with ethanol, and dried at 150° C. for 8 h in vacuum to obtain the MOF-5 material.

Embodiment 2

[0029] A method for preparing a hydrophobic double MOF-based porous carbon material, comprising the steps of:

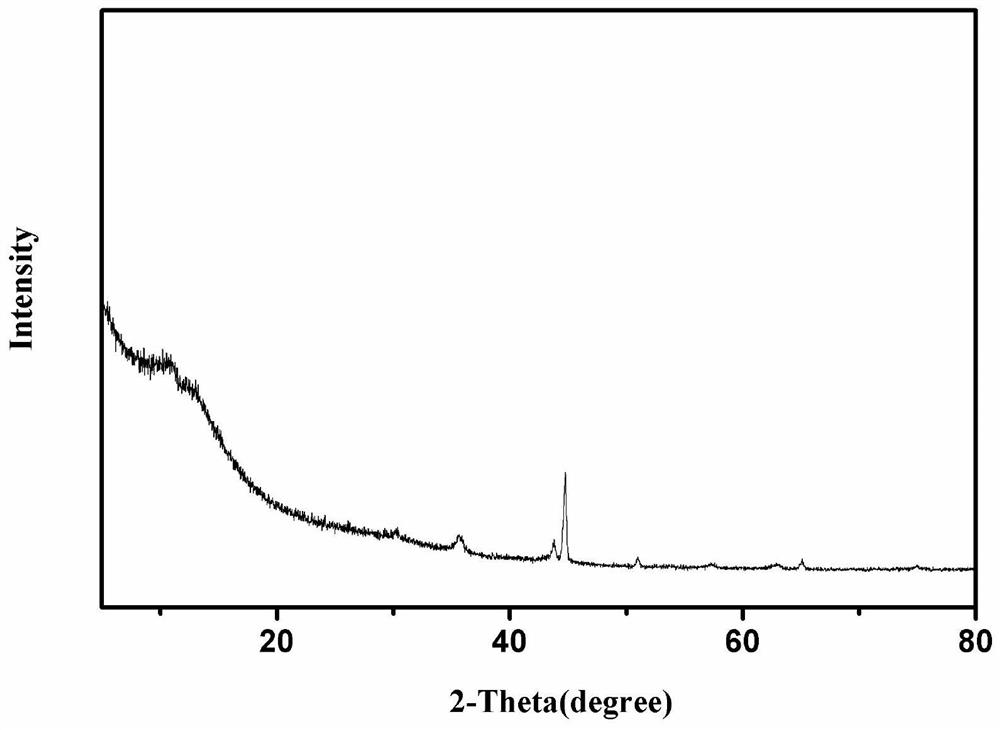

[0030] Mix 0.6g of MOF-5 material with 0.1g of MIL-100(Fe) and put it into a tube furnace. Under the protection of nitrogen, the temperature is raised to 900°C at 5°C / min and maintained for 6h to obtain a hydrophobic double MOF-based porous carbon. Material.

Embodiment 3

[0032] A method for preparing a hydrophobic double MOF-based porous carbon material, comprising the steps of:

[0033] Mix 0.56g of MOF-5 material and 0.14g of MIL-100(Fe) evenly, put it into a tube furnace, and raise the temperature to 900°C at 10°C / min under the protection of nitrogen for 5h to obtain hydrophobic double MOF-based porous carbon Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com