A treatment process for low-quality sulfur in coal chemical industry

A treatment process and low-quality technology, applied in the direction of sulfur preparation/purification, etc., can solve the problems of unsafe product purity, high energy consumption of treatment technology, large pollution, etc., to improve dynamic stability and water damage resistance, improve The effect of road engineering quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

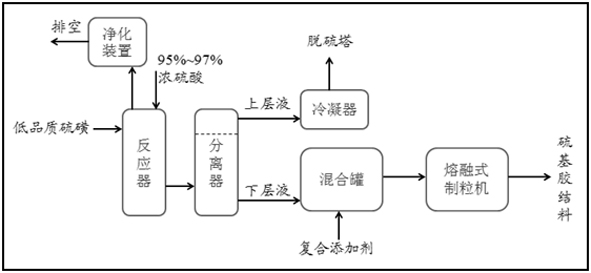

[0022] Step 1: Add 1kg of low-quality sulfur to the reactor, add 12g of 95% concentrated sulfuric acid at the same time, adjust the temperature of the reactor to 130°C, and react for 2 hours. Stirring is required during the reaction, and the rotation speed is 40 rpm. The reaction is completed Afterwards, it flows by itself in liquid form or is pumped into the separator, and the gas at the top is treated by a purification device and then emptied.

[0023] Step 2: Keep the temperature of the separation tank at 135°C and separate for 2 hours. The separated upper liquid is cooled by the condenser and then returned to the desulfurization system, and the lower liquid enters the mixer in liquid form.

[0024] Step 3: Keep the temperature in the mixer at 120°C~150°C, add 20g of low-temperature extension agent, 40g of poison inhibitor, 50g of anti-peeling agent, and 20g of plasticizer into the mixer. The mixing process needs to be supplemented by stirring. The stirring speed is 100 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com