Cement core board and preparation method thereof

A core board and cement technology, which is applied in the field of preparation of cement core boards, can solve the problems of shortage of magnesium oxide supply, existence of magnesium oxide supply, tight supply of raw materials, etc., and achieves weak corrosion strength, large market scope and market scope narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A cement core board comprising the following components in parts by weight: 50 parts of sulfoaluminate cement; 25 parts of water; 1 part of polyacrylonitrile fiber; 0.15 part of seaweed powder; 0.25 part of calcium stearate and sodium tripolyphosphate 0.05 parts.

[0013] Its preparation method is as follows: Add the sulfoaluminate cement, polyacrylonitrile fiber, seaweed powder, calcium hardate and sodium tripolyphosphate in the formula in order to stir, then add water, stir for 3 to 5 minutes, and then add foam Foaming is carried out, and then stirred for 3 to 5 minutes. After the foam is evenly mixed, the slurry is spread into a mold for board making.

[0014] In this embodiment, the fiber length of seaweed powder is 2-3 cm.

[0015] The fire performance of the prepared cement core board meets the requirements of the national mandatory standard GB 12955-2008.

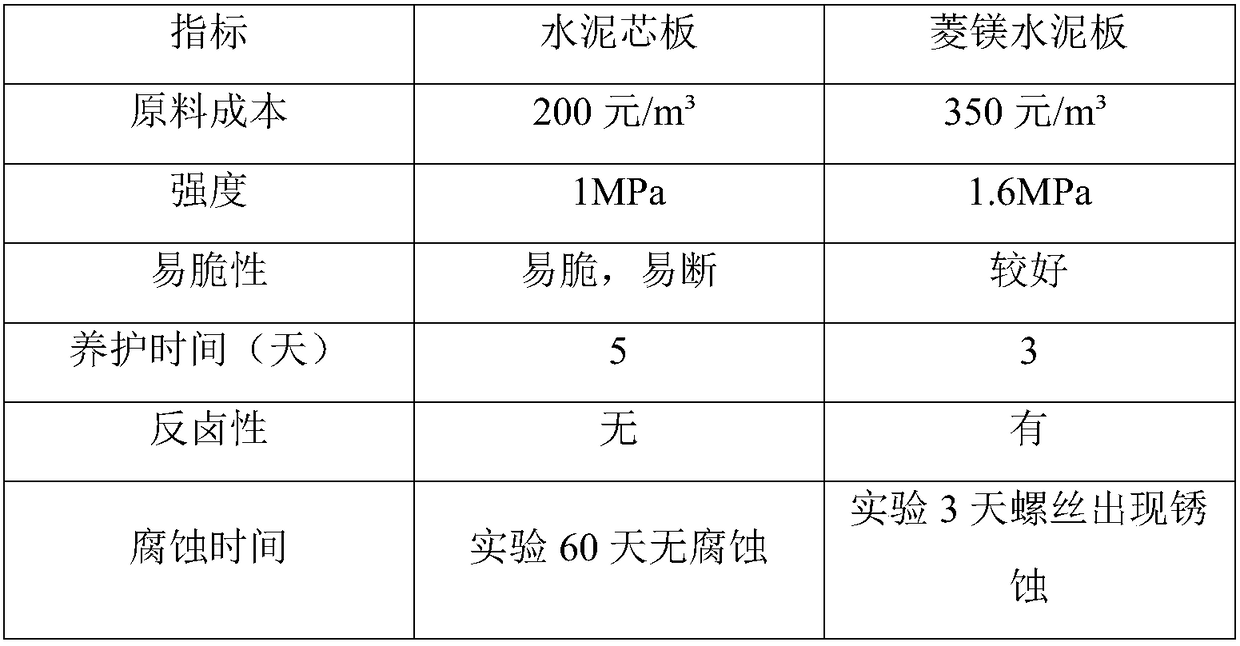

[0016] Comparing other indicators with magnesite cement board, the results are shown in Table 1.

[0017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com