SPCC steel drum performance optimization heat treatment method

A heat treatment method and steel drum technology, applied in heat treatment baths, heat treatment furnaces, heat treatment equipment, etc., can solve environmental problems such as pollution, resource waste, etc., and achieve the effects of reducing the risk of rupture, increasing fatigue resistance time, and increasing elongation

Inactive Publication Date: 2018-11-13

上海出入境检验检疫局工业品与原材料检测技术中心

View PDF4 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, at present, domestic steel drums are used for one-time use due to vibration during transportation,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

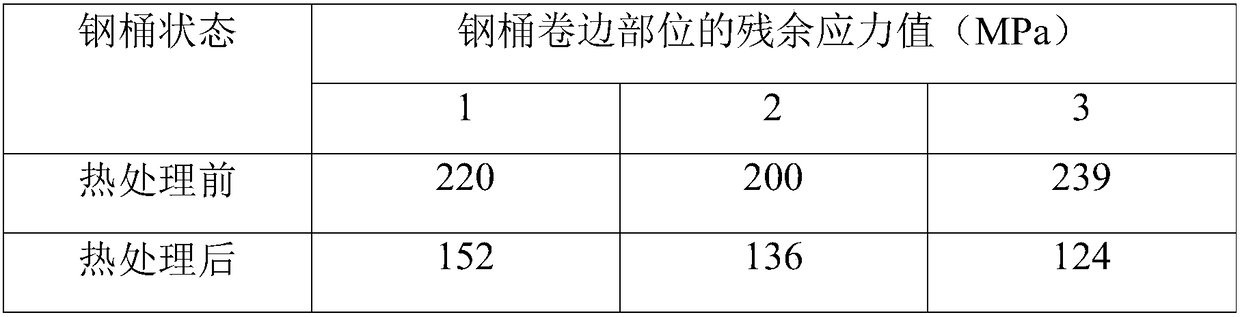

The invention discloses an SPCC steel drum performance optimization heat treatment method. The method comprises the following steps that firstly, a steel drum is cleaned and subjected to leakage inspection before heat treatment of the SPCC steel drum; secondly, the temperature of a salt bath furnace is set to be 200 DEG C-250 DEG C, the SPCC steel drum is hoisted to a position above the salt bathfurnace after the temperature reaches 200 DEG C-250 DEG C, a bottom cover of the SPCC steel drum is kept horizontal while being immersed into the salt bath furnace, the immersion depth is 38-42 mm, the SPCC steel drum is subjected to heat preservation in the salt bath furnace for 10 min-15 min under the condition that the immersion depth is 38-42 mm and the temperature is 200 DEG C-250 DEG C, andthen the SPCC steel drum is taken out of the furnace and air-cooled to the room temperature; and thirdly, salt on the surface of the SPCC steel drum which is heated and cooled in the second step is cleaned. According to the SPCC steel drum performance optimization heat treatment method, the performance of a new drum which is not used yet can be improved, and the risk of fracturing is lowered; andthe steel drum after transportation can also be saved from fatigue impact, the service life is prolonged, accordingly, reuse is achieved, and the characteristics of the mechanical performance, the fatigue resistance and the like of the whole steel drum are improved.

Description

technical field [0001] The invention belongs to the field of heat treatment technology, and in particular relates to a performance-optimized heat treatment method for an SPCC steel drum. Background technique [0002] Packaging steel drums are a widely used container. With my country's accession to WTO and the expansion of international trade, the scope of use of steel drums has become increasingly widespread, and great changes have taken place in transportation methods and transportation distances. Liquid dangerous chemicals are the most sensitive dangerous goods, and closed steel drums are one of the main transport packaging containers for exporting liquid dangerous chemicals. More than 90% of steel drums on the market are made of SPCC materials. Due to work hardening and edge effects, the curling of steel drums has become a stress concentration point and a weak point in mechanical properties, so most of the leakage points of leaked steel drums are concentrated in the cur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21D9/00C21D1/46

CPCC21D9/0068C21D1/46

Inventor 吉静初敏楚民生王彪朱洪坤

Owner 上海出入境检验检疫局工业品与原材料检测技术中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com