Hot-dip galvanized steel plate and preparation method thereof

A hot-dip galvanized steel sheet, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problem of high cost, achieve stable performance, excellent surface quality, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing the above-mentioned hot-dip galvanized steel sheet, which includes the following steps: the molten steel is smelted and continuously cast to obtain a slab, and the slab is heated-dephosphorization-rough rolling-finish rolling-cooling-coiling-pickling -After the cold rolling-annealing-hot-dip galvanizing process, a hot-dip galvanized steel sheet is obtained.

[0025] In the preparation process of the above-mentioned hot-dip galvanized steel sheet, the hot rolling is finished in the austenite region close to Ar3, so it needs to be heated to 1150°C-1200°C for rough rolling, so the heating temperature needs to be controlled at 1200-1250°C. In order to ensure uniform temperature at the head and tail of the steel coil, it is necessary to control the temperature range of the finish rolling at 860°C to 930°C, and after finishing rolling to cool to a temperature range of 590°C to 670°C for coiling, so as to obtain a fine ...

Embodiment 1-2

[0028] Hot-dip galvanized steel sheet composition of the present invention and preparation technology are specifically as follows:

[0029] (1) Through smelting and continuous casting process, the steel slab of chemical composition as shown in the following table 1 is prepared:

[0030] Table 1 Steel Slab Chemical Composition (wt.%)

[0031] Numbering

C

Si

mn

P

S

als

Example 1

0.07

0.04

0.22

0.03

0.003

0.052

Example 2

0.11

0.01

0.45

0.01

0.008

0.029

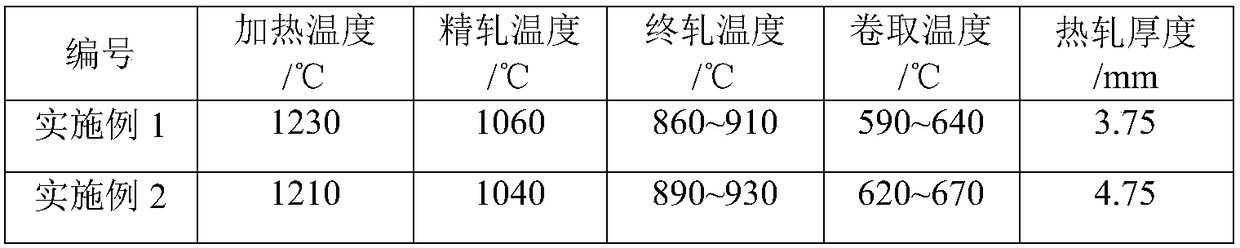

[0032] (2) The hot rolling process parameters such as heating, rough rolling, finish rolling, cooling, and coiling are shown in Table 2 below:

[0033] Table 2 Main process parameters of hot rolling

[0034]

[0035] (3) Pickling and cold-rolling the hot-rolled coils into thin steel strips, wherein the cold-rolling reductions in Examples 1 and 2 are 70.3% and 61.3% respectively;

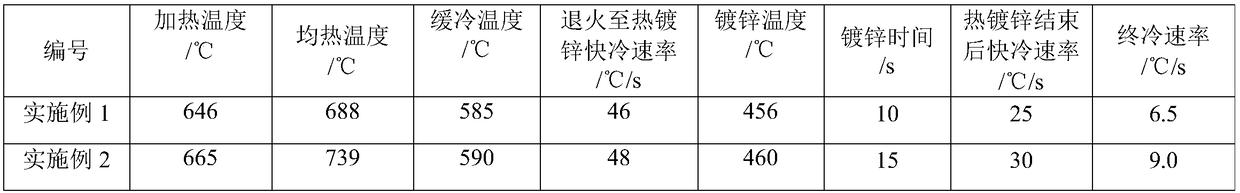

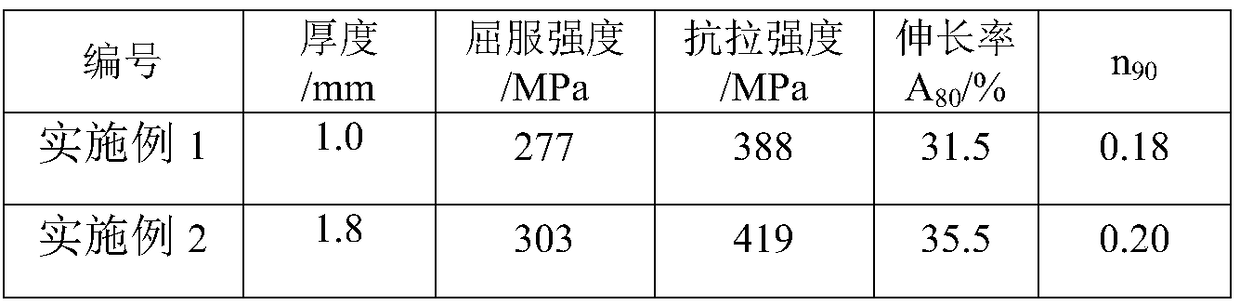

[0036] (4) The annealing and hot-dip galvanizing process par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com