Method for crystal grain homogenization of GH3128 high-temperature alloy

A technology of GH3128 and high-temperature alloy, which is applied in the field of forging technology, can solve the problems of ineffective correction, waste of resources, and easy occurrence of mixed crystals, etc., and achieve the effects of improving batch scrapping, saving production costs, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The GH3128 superalloy crystal grain homogenization method of the present embodiment, its specific process step is as follows:

[0035] Step 1: Heating: After heating the coarse-grained GH3128 rod to 1125°C, keep it warm for 100 minutes;

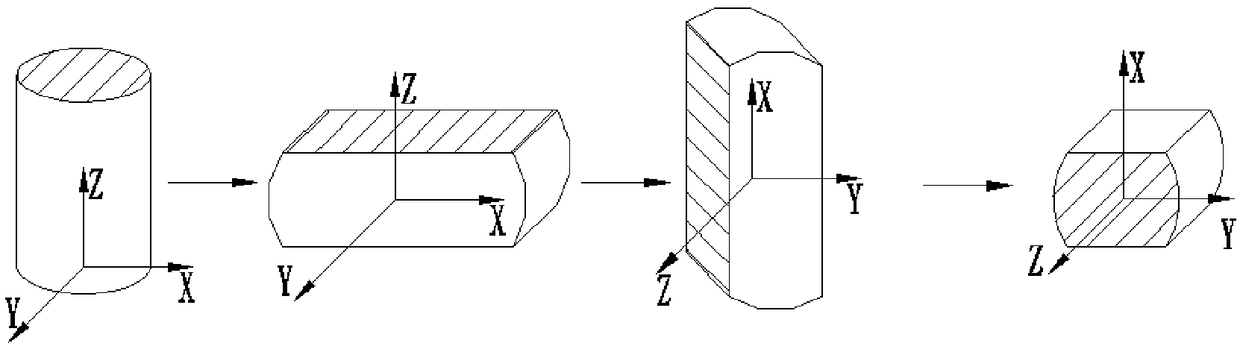

[0036] Step 2: If figure 1 As shown, X-axis radial elongation and upsetting: place one end of the bar processed in step 1 perpendicular to the Z-axis on the press platform, and alternately forge along the Z-axis and Y-axis respectively, so that the bar The material is drawn along the X-axis direction; then the end surface of the bar material perpendicular to the X-axis is placed on the press platform, and it is upset along the X-axis direction, and the height of the upsetting to the X-axis direction is equal to the original bar size before processing;

[0037] Step 3: Return the hot material to the furnace: return the bar obtained in step 2 to the furnace for heating for 70 minutes;

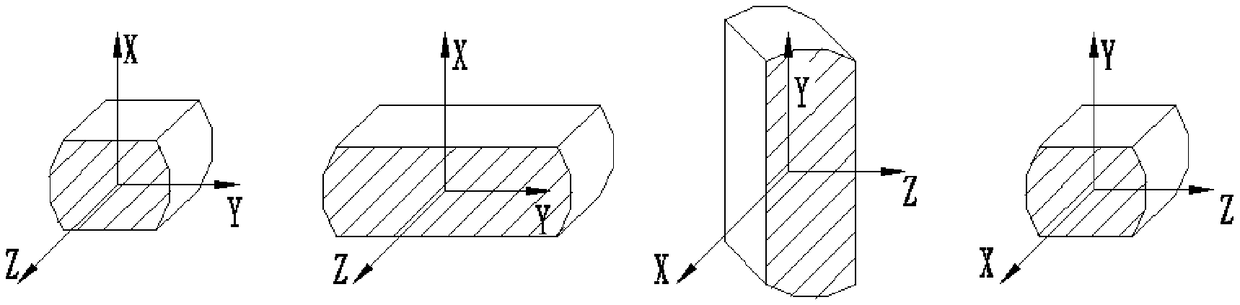

[0038] Step 4: If figure 2 As shown, Y-axis rad...

Embodiment 2

[0043] The GH3128 superalloy crystal grain homogenization method of the present embodiment, its specific process step is as follows:

[0044] Step 1: Heating: After heating the coarse-grained GH3128 rod to 1130°C, keep it warm for 90 minutes;

[0045] Step 2: If figure 1 As shown, X-axis radial elongation and upsetting: place one end of the bar processed in step 1 perpendicular to the Z-axis on the press platform, and alternately forge along the Z-axis and Y-axis respectively, so that the bar The material is drawn along the X-axis direction; then the end surface of the bar material perpendicular to the X-axis is placed on the press platform, and it is upset along the X-axis direction, and the height of the upsetting to the X-axis direction is equal to the original bar size before processing;

[0046] Step 3: return the hot material to the furnace: return the bar obtained in step 2 to the furnace for heating for 60 minutes;

[0047] Step 4: If figure 2 As shown, Y-axis radi...

Embodiment 3

[0052] The GH3128 superalloy crystal grain homogenization method of the present embodiment, its specific process step is as follows:

[0053] Step 1: Heating: After heating the coarse-grained GH3128 rod to 1120°C, keep it warm for 120 minutes;

[0054] Step 2: If figure 1 As shown, X-axis radial elongation and upsetting: place one end of the bar processed in step 1 perpendicular to the Z-axis on the press platform, and alternately forge along the Z-axis and Y-axis respectively, so that the bar The material is drawn along the X-axis direction; then the end surface of the bar material perpendicular to the X-axis is placed on the press platform, and it is upset along the X-axis direction, and the height of the upsetting to the X-axis direction is equal to the original bar size before processing;

[0055] Step 3: return the hot material to the furnace: return the bar obtained in step 2 to the furnace for heating for 80 minutes;

[0056] Step 4: If figure 2 As shown, Y-axis radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com