Auxiliary agent for liquid multi-color dyeing and using method thereof

A liquid multi-combination and auxiliary technology, applied in the field of dyeing auxiliaries, can solve the problems of unstable dyeing and high cost, and achieve the effects of excellent environmental protection performance, easy treatment and simple wastewater composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

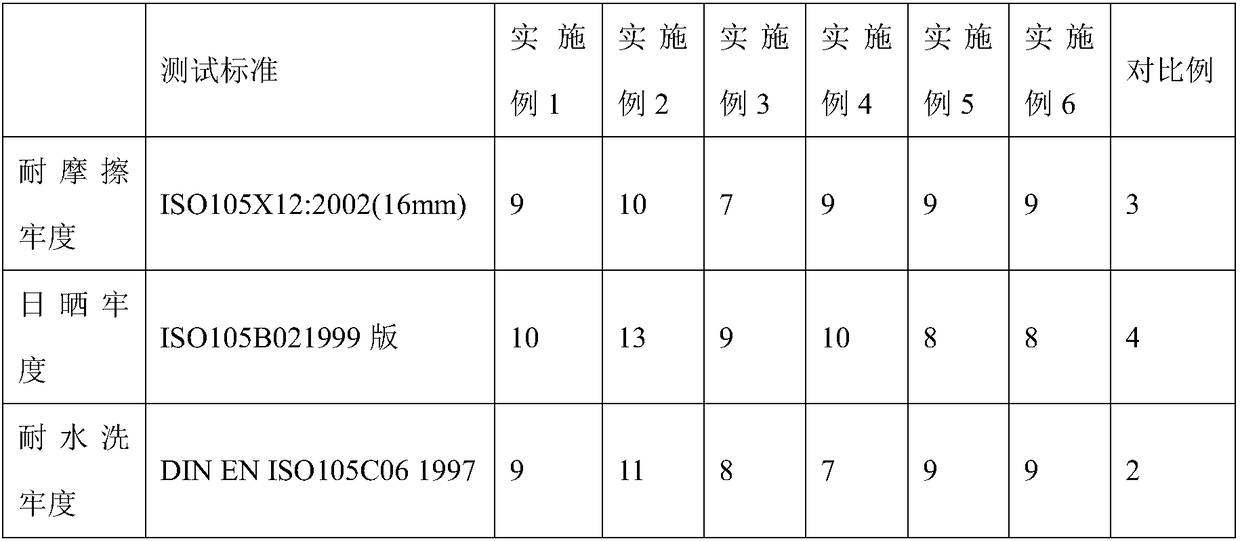

Examples

Embodiment 1

[0029] The auxiliaries for liquid multi-color dyeing provided in this example include the following components in parts by mass: 3 parts of sodium hydroxide, 0.1 part of chelating agent, 0.2 part of sodium hexametaphosphate, and 0.7 parts of color-fixing agent Parts, dispersant WA: 0.5 part and anti-swimming agent PA 0.5 part and appropriate amount of water mixed solution, the pH value of the solution is 8.5.

[0030] Its use method is as follows: S1, weigh the components in parts by mass sequentially to weigh sodium hydroxide, chelating agent, sodium hexametaphosphate, add water to disperse and dissolve, and the dosage ratio is 1:20; S2, at room temperature, put Stir in a mixer for 10-20 minutes to obtain a disperse dye suspension; S3, add color-fixing agent Y, dispersant WA and anti-swimming agent PA to the solution and continue stirring for 6-8 hours to obtain auxiliaries and dye combinations The particle size of the product is 0.1-1μm; S4, add dyeing solution and auxiliary...

Embodiment 2

[0032] A liquid multi-component dyeing auxiliary, comprising the following components in parts by mass: 5 parts of sodium hydroxide, 0.15 parts of a chelating agent, 0.2 parts of sodium hexametaphosphate, 1 part of color-fixing agent Y, and 1 part of dispersing agent WA 1 part and 1 part of anti-swimming agent PA and an appropriate amount of water, the pH value of the solution is 8.5.

[0033]Its use method is as follows: S1, weigh the components in parts by mass successively, weigh sodium hydroxide, chelating agent, sodium hexametaphosphate, add water to disperse and dissolve, and the dosage ratio is 1:20; S2, at room temperature, put Stir in a mixer for 10-20 minutes to obtain a disperse dye suspension; S3, add color-fixing agent Y, dispersant WA and anti-swimming agent PA to the solution and continue stirring for 6-8 hours to obtain auxiliaries and dye combinations The particle size of the product is 0.1-1μm; S4, add dyeing solution and auxiliary agent at room temperature o...

Embodiment 3

[0035] A liquid multi-component dyeing auxiliary, comprising the following components in parts by mass: 4 parts of sodium hydroxide, 0.1 part of chelating agent, 0.1 part of sodium hexametaphosphate, 0.1 part of color fixing agent Y, dispersant WA : 0.1 part and 0.1 part of anti-swimming agent PA and appropriate amount of water mixed solution, the pH value of the solution is 8.5.

[0036] Its use method is as follows: S1, weigh the components in parts by mass successively, weigh sodium hydroxide, chelating agent, sodium hexametaphosphate, add water to disperse and dissolve, and the dosage ratio is 1:20; S2, at room temperature, put Stir in a mixer for 10-20 minutes to obtain a disperse dye suspension; S3, add color-fixing agent Y, dispersant WA and anti-swimming agent PA to the solution and continue stirring for 6-8 hours to obtain auxiliaries and dye combinations The particle size of the product is 0.1-1μm; S4, add dyeing solution and auxiliary agent at room temperature of 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com