Fixing device for pre-embedded casing pipe and reserved hole and using method

A technology of fixing device and reserved holes, which is applied to on-site preparation of building components, formwork/template/work frame, construction, etc., can solve the problem of inconvenient fixing method of pre-embedded casing steel wire binding and invalidation of reserved holes for casing. , pipeline installation difficulties and other problems, to achieve the effect of fast and convenient production, reduced engineering costs, and fast dismantling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention is used for a fixing device for pre-embedded sleeves and reserved holes, and the fixing device is used in the binding of reinforced concrete reinforcement, including a bottom plate and a screw rod.

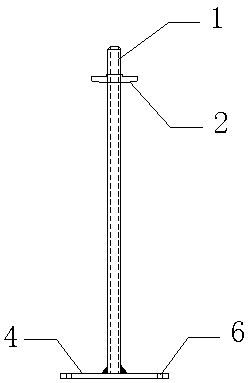

[0034] see now figure 1 , figure 1 It is a structural schematic diagram of the fixing device of the embodiment of the present invention. As shown in the figure, the bottom plate 4 is a rectangular steel plate with a size of 40×80 mm and a thickness of 5 mm, and two screw holes 6 with a diameter of 3 mm are provided on the edge of the bottom plate.

[0035] The screw 1 is a full-wire screw with a diameter of 12mm, and the screw is equipped with a nut 2; the length of the screw is 20mm greater than the design thickness of the reinforced concrete.

[0036] Wherein: one end of the screw rod 1 is welded and fixed to the center of the bottom plate, so that the screw rod is perpendicular to the bottom plate.

Embodiment 2

[0038] A method for using a fixing device for pre-embedded casings and reserved holes. The fixing device is used in a steel bar binding frame for reinforced concrete, comprising the following steps:

[0039] a. Prefabricated fixtures for pre-embedded casing and reserved holes

[0040] According to the setting requirements of the embedded casing and the reserved hole, including the diameter size of the embedded casing or the reserved hole, the corresponding size of the bottom plate 4 is selected.

[0041] b. Fixing of fixtures

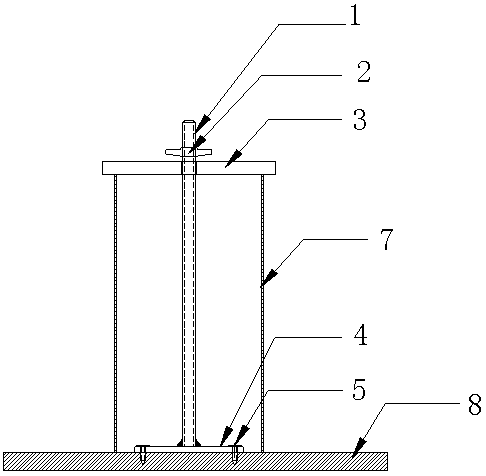

[0042] According to the center of circle positioning of the pre-embedded casing, the fixed device made is fixed on the bottom formwork 8 of the steel bar binding frame of the reinforced concrete of the floor slab with a screw 5, and the fixing firmness is checked;

[0043] c. After the fixing device is firmly fixed, put the embedded casing 7 on the screw 1 of the fixing device, adjust the position of the embedded casing so that the axis of the embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com