Selective hydrophobic treatment method for air holes of hollow-core photonic crystal fiber

A technology of hollow-core photonic crystal and hydrophobic treatment, which is applied in cladding optical fiber, microstructure optical fiber, optical waveguide and light guide, etc., can solve the problems of not being greatly affected, achieve long processing length, facilitate integrated application, and save time and material cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to express the purpose, technical route and advantages of the present invention more clearly, the present invention will be further elaborated below in conjunction with the accompanying drawings.

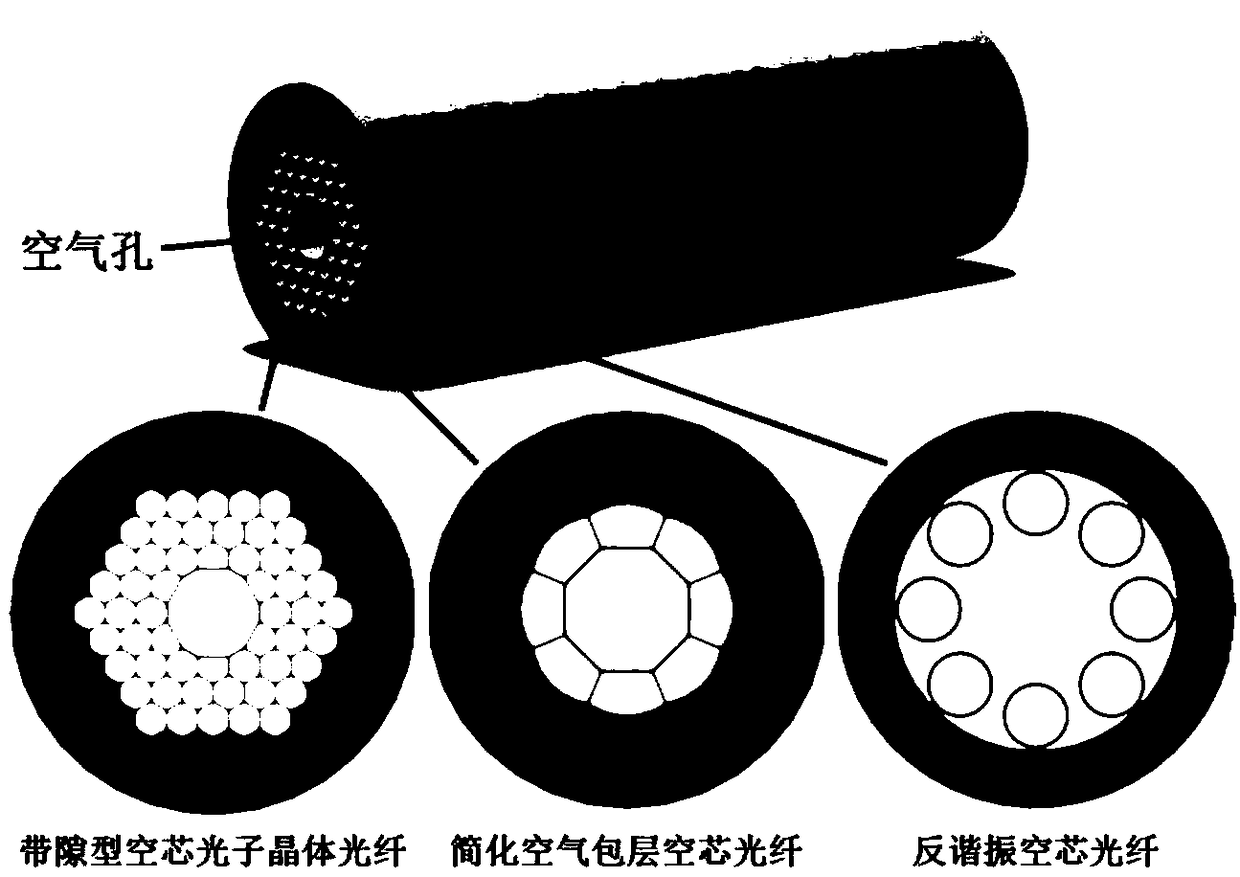

[0025] Such as figure 1 As shown, the hollow-core photonic crystal fiber is composed of smaller cladding holes periodically arranged around, a larger core hole in the center, and a cladding structure on the periphery. The cladding layer is generally silicon dioxide, the refractive index is about 1.45 at 1550 nm, and the cladding hole and the core hole are air. The hollow-core photonic crystal fiber confines the light field through a special periodic arrangement structure, which makes the light propagate in the core hole. The change of the medium in the air hole will cause the change of the light field distribution.

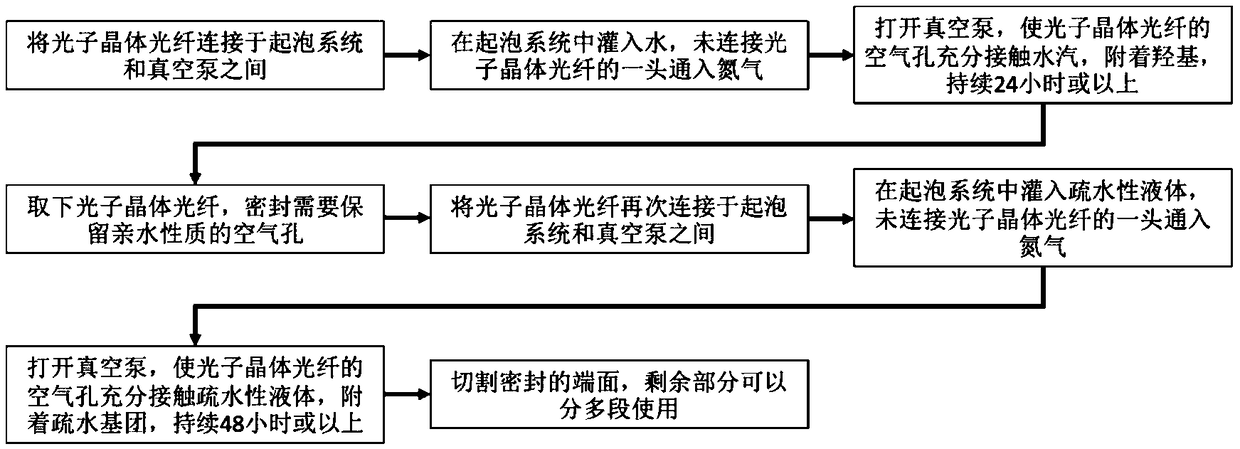

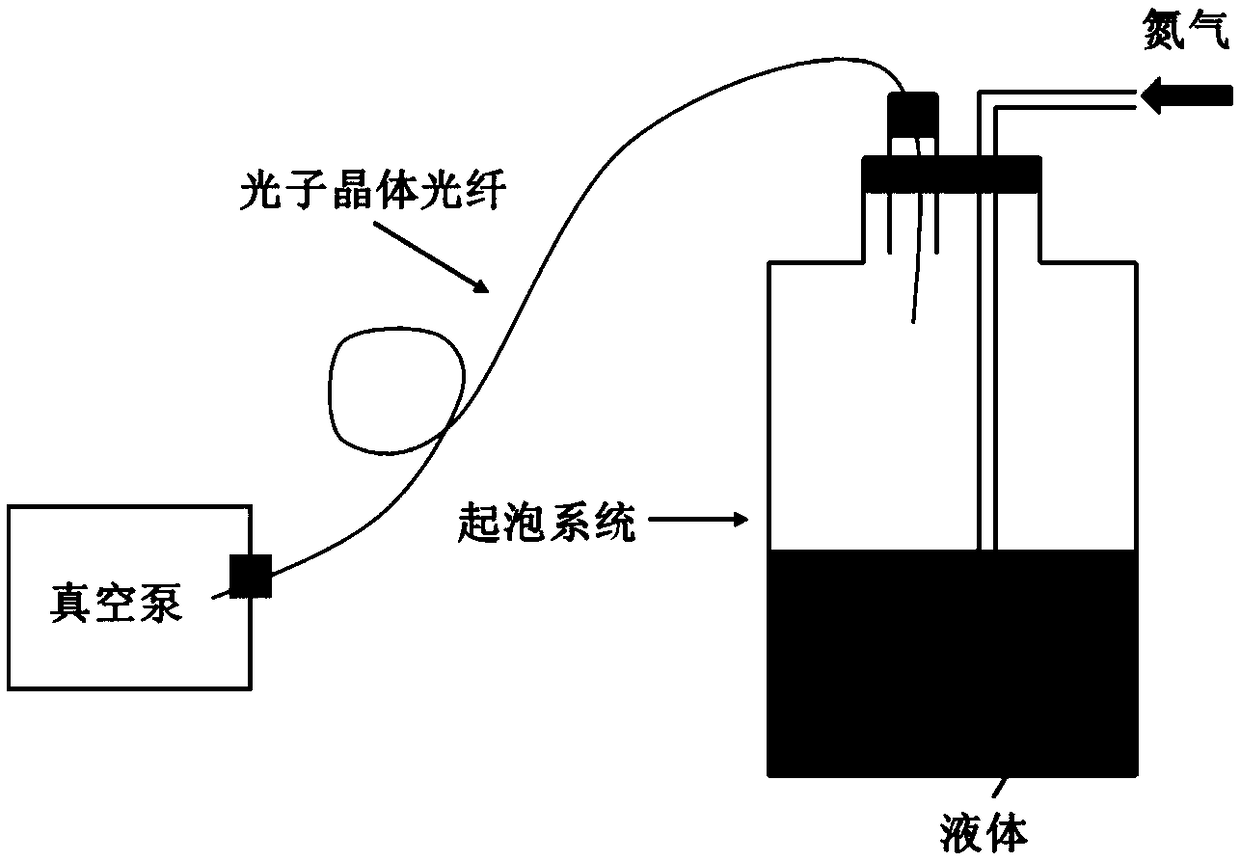

[0026] Such as figure 2 As shown, the present invention uses the solidification of the curable liquid or the selective collapse of the air holes by thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com