Super-resolution optical microscopic imaging system and adjusting method thereof

An optical microscopy and imaging system technology, applied in the field of super-resolution imaging, can solve the problems of poor multi-wavelength beam shaping effect, poor spot shaping effect of solid beam and loss beam, and poor beam intensity distribution shaping effect, etc. Achieve the effect of improving imaging resolution, optimizing implementation, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

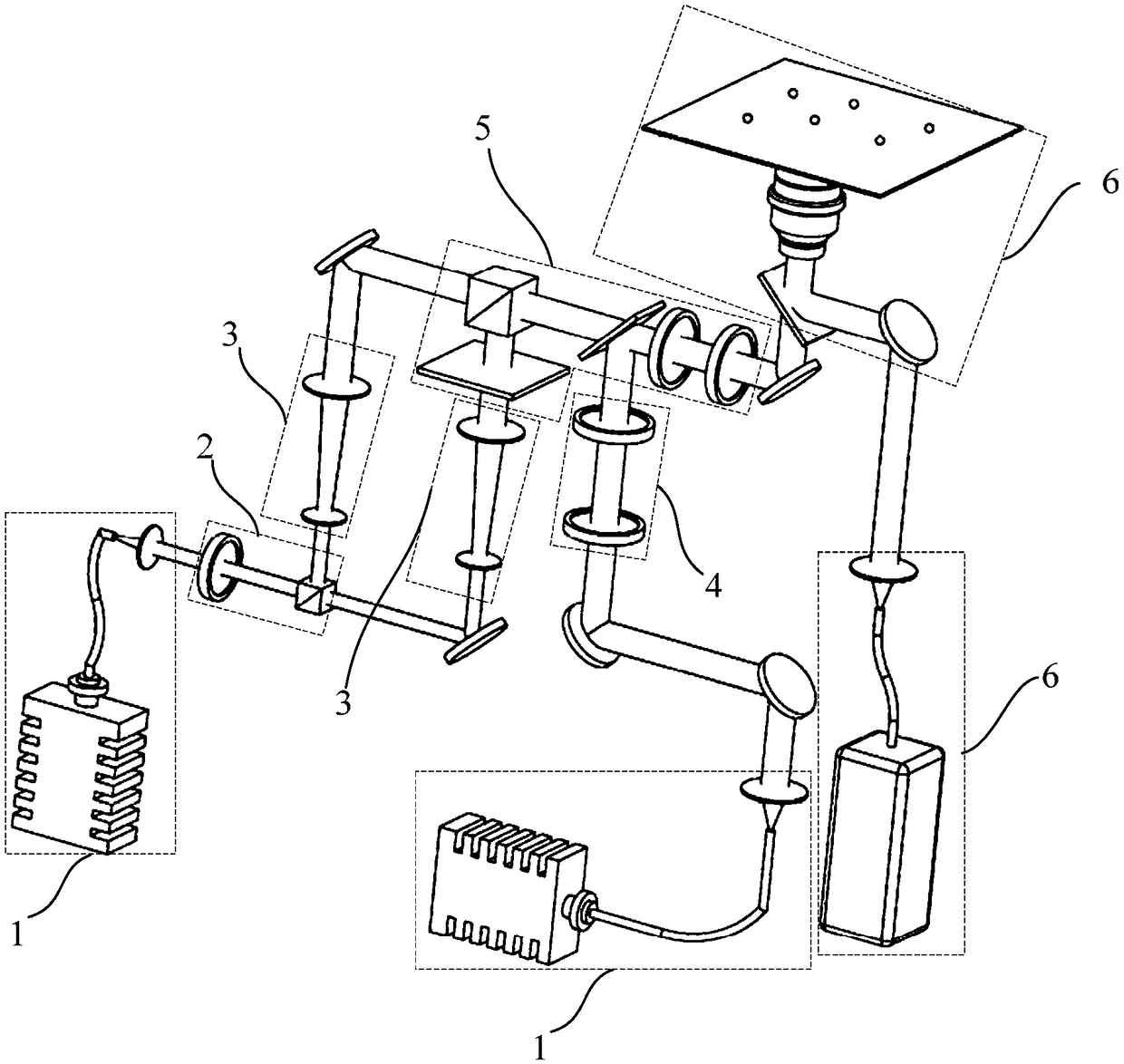

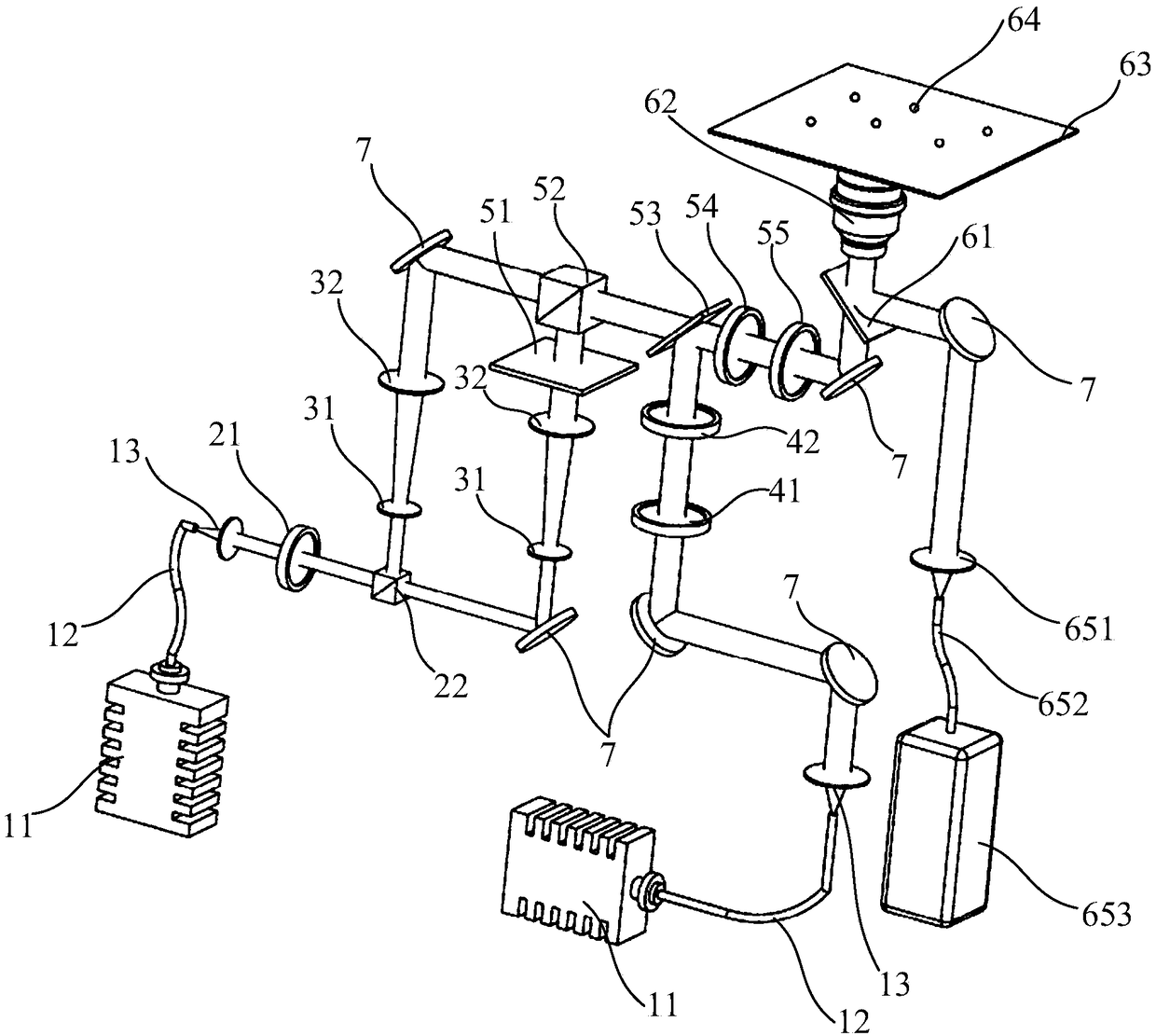

[0056] see Figure 1 to Figure 7 . It should be noted that the diagrams provided in this embodiment are only schematically illustrating the basic idea of the present invention, and only the components related to the present invention are shown in the diagrams rather than the number, shape and shape of the components in actual implementation. Dimensional drawing, the type, quantity and proportion of each component can be changed arbitrarily during actual implementation, and the component layout type may also be more complicated.

[0057] Such as figure 1 and figure 2 As shown, the present invention provides a super-resolution optical microscopic imaging system, the super-resolution optical microscopic imaging system includes: two laser light source shaping modules 1, a beam splitting module 2, two beam expanding modules 3, a first solid Beam adjustment module 4, a hollow beam modulation and beam coincidence adjustment module 5, a scanning imaging and detection module 6; ...

Embodiment 2

[0076] This embodiment is an adjustment method for the super-resolution optical microscopy imaging system proposed based on the first embodiment, and the adjustment step includes:

[0077] 1) In the laser light source shaping module 1, the optical fiber 12 and the collimating lens 13 respectively shape and collimate the light spots of the first laser beam and the second laser beam;

[0078] 2) In the scanning imaging and detection module 6, the objective lens 62 focuses the coincident light and irradiates it onto the gold nanoparticles 64, and is emitted to the The imaging device completes the real-time imaging process;

[0079] 3) According to the real-time imaging effect, adjust the hollow beam modulation and beam coincidence adjustment module 6 to complete the shaping adjustment of the coincidence light and the coincidence degree adjustment of the coincidence light.

[0080] As an example, the diameter of the gold nanoparticles 64 is between 70 nm˜90 nm.

[0081] This emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com