Box-in-box type machine tool beam optimization design method using recombination of multiple ribbed plate structures

A technology for optimized design and beams, applied in design optimization/simulation, calculation, genetic rules, etc., can solve problems such as redundant rib materials, increase in the overall quality of beams, and the inability to guarantee optimal design effects, etc., to achieve strong engineering practicability, The effect of improving stability and reducing redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

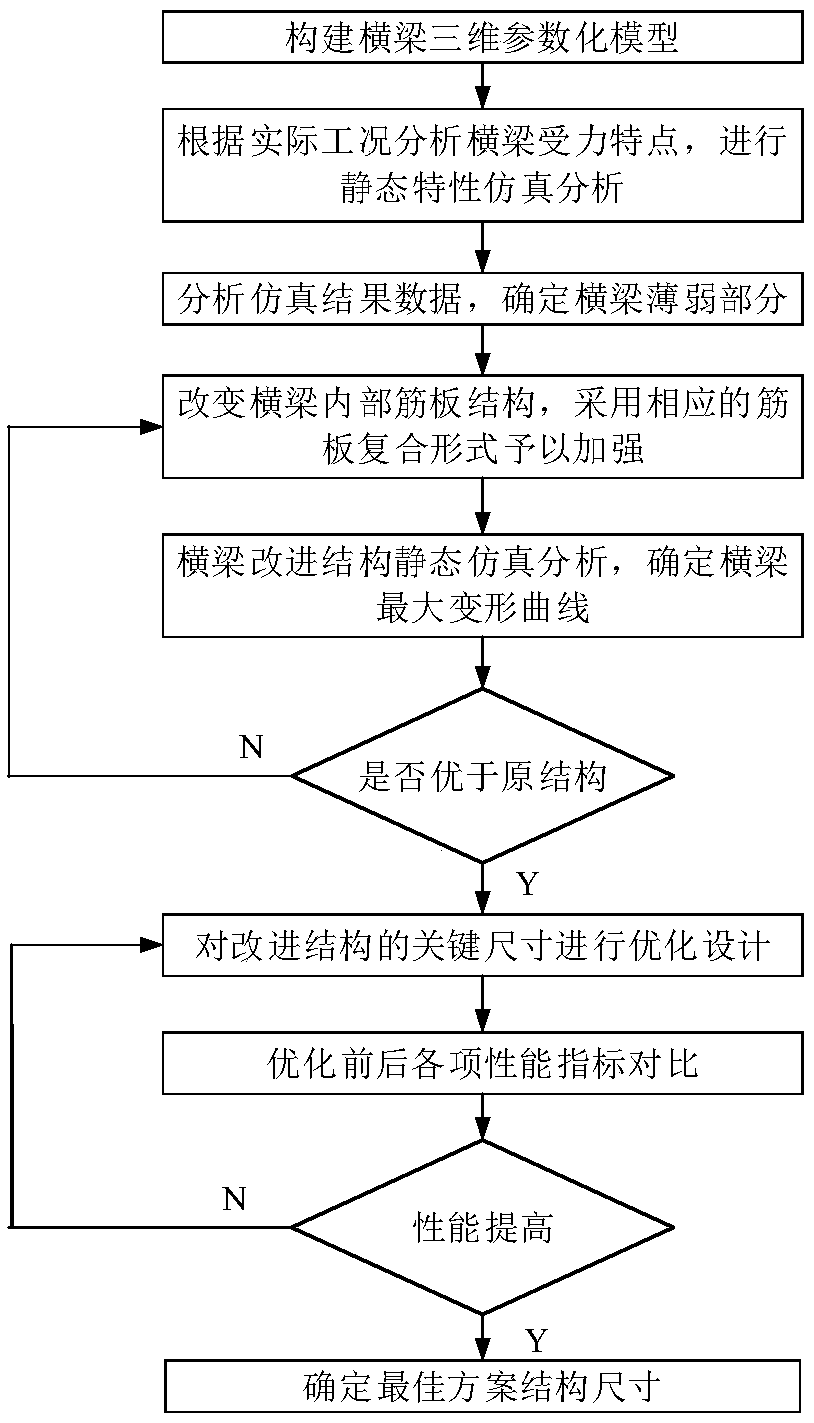

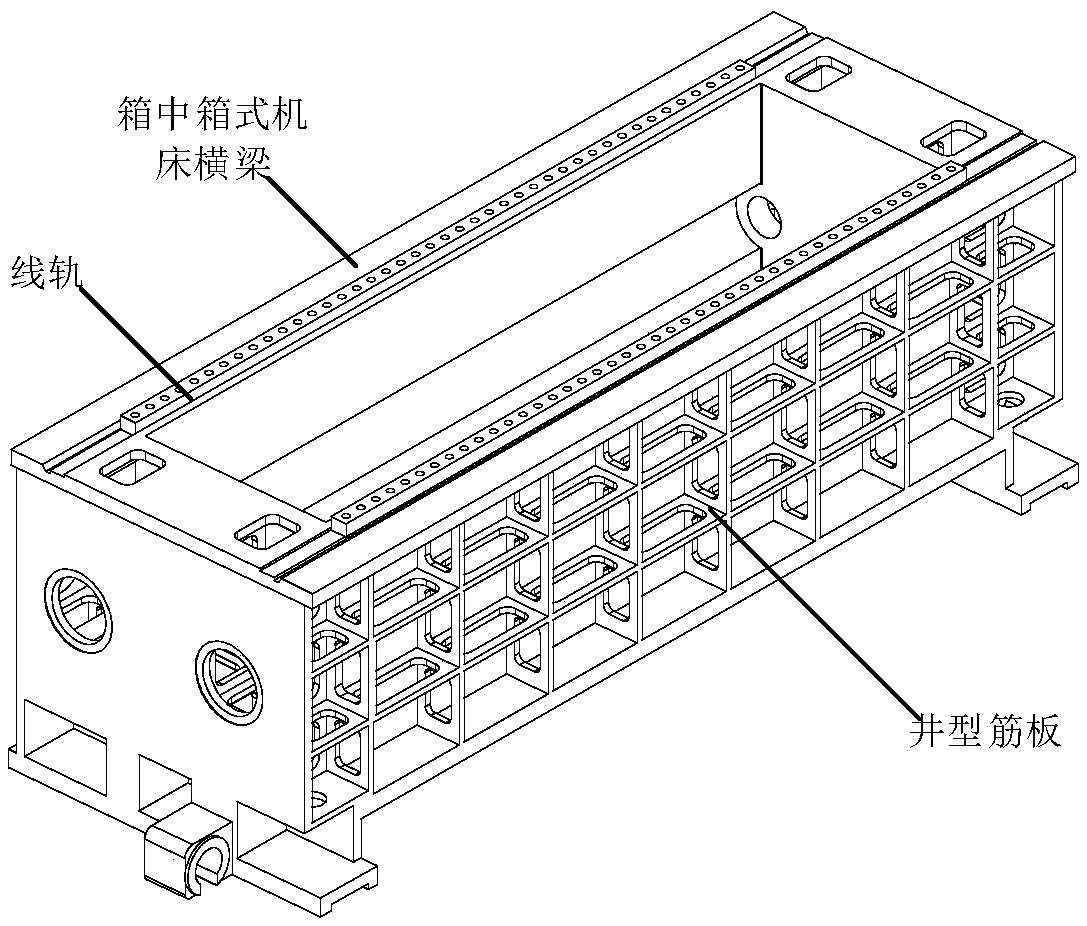

[0032] The present invention takes bridge-type gantry milling machine beam structure design improvement as an example, and the specific implementation process is as follows figure 1 shown. Firstly, construct the parametric model of the initial three-dimensional structure of the machine tool beam, such as figure 2 shown.

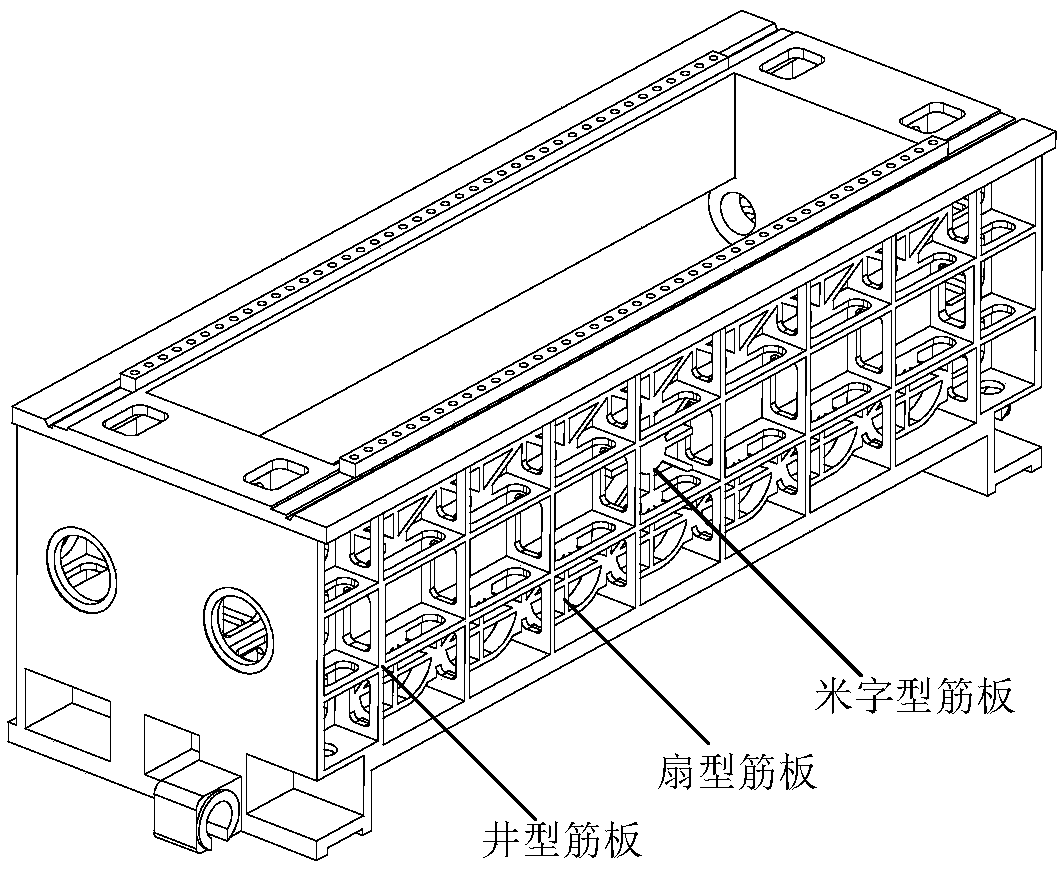

[0033] Then analyze the force characteristics of the beam according to the actual working conditions, import it into the finite element analysis software, and carry out the static characteristic simulation analysis of the action conditions of the beam at different positions of the machine tool slide assembly within the travel range of the beam line rail. Select the center of the force-bearing surface from the leftmost side of the beam, and analyze the static characteristics of different positions at intervals of 200mm, and obtain the maximum deformation of the beam at the corresponding position. Analysis of the simulation result data of the machine tool cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com