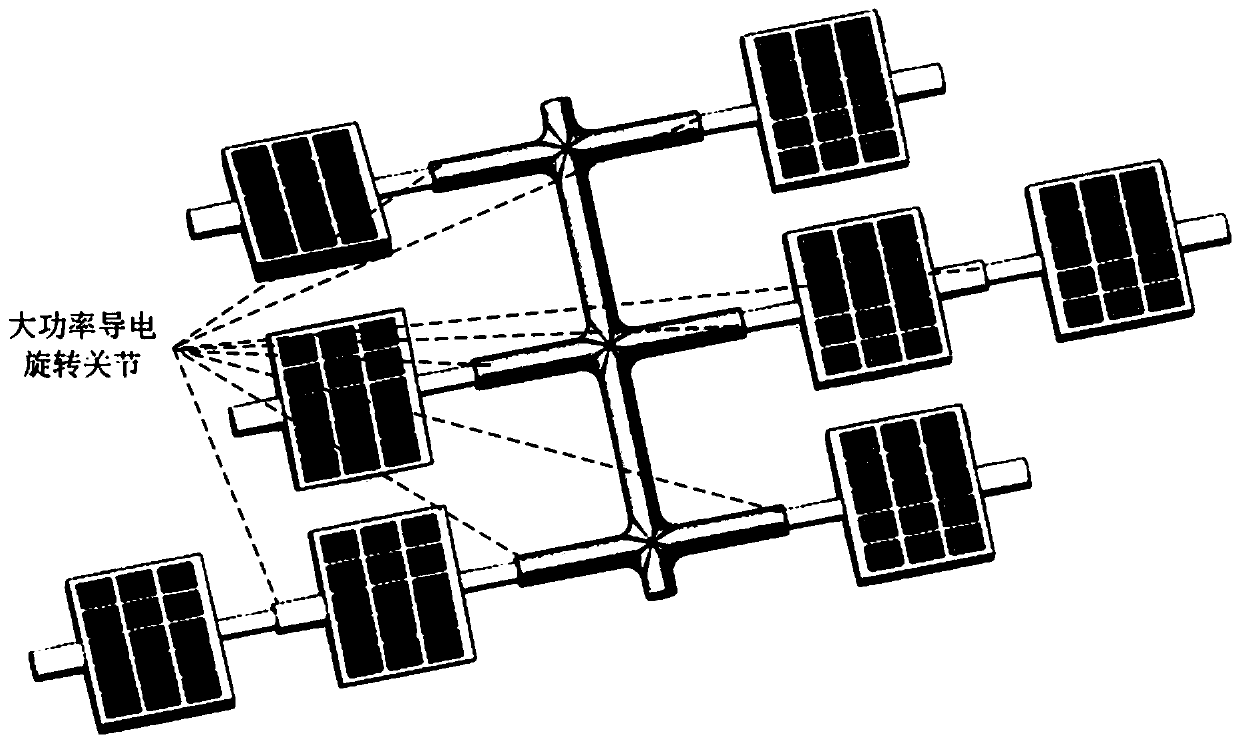

A high-current conductive rotary joint for solar subarray power transmission

A technology of conductive rotary joints and solar sub-arrays, applied in flexible/rotatable wire connectors, circuits, electrical components, etc., can solve the problems affecting the overall efficiency of energy conversion and transmission systems, difficult space solar power plants, and large contact resistance. , to achieve the effect of ensuring mechanical properties, improving electrical conductivity and long electrical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

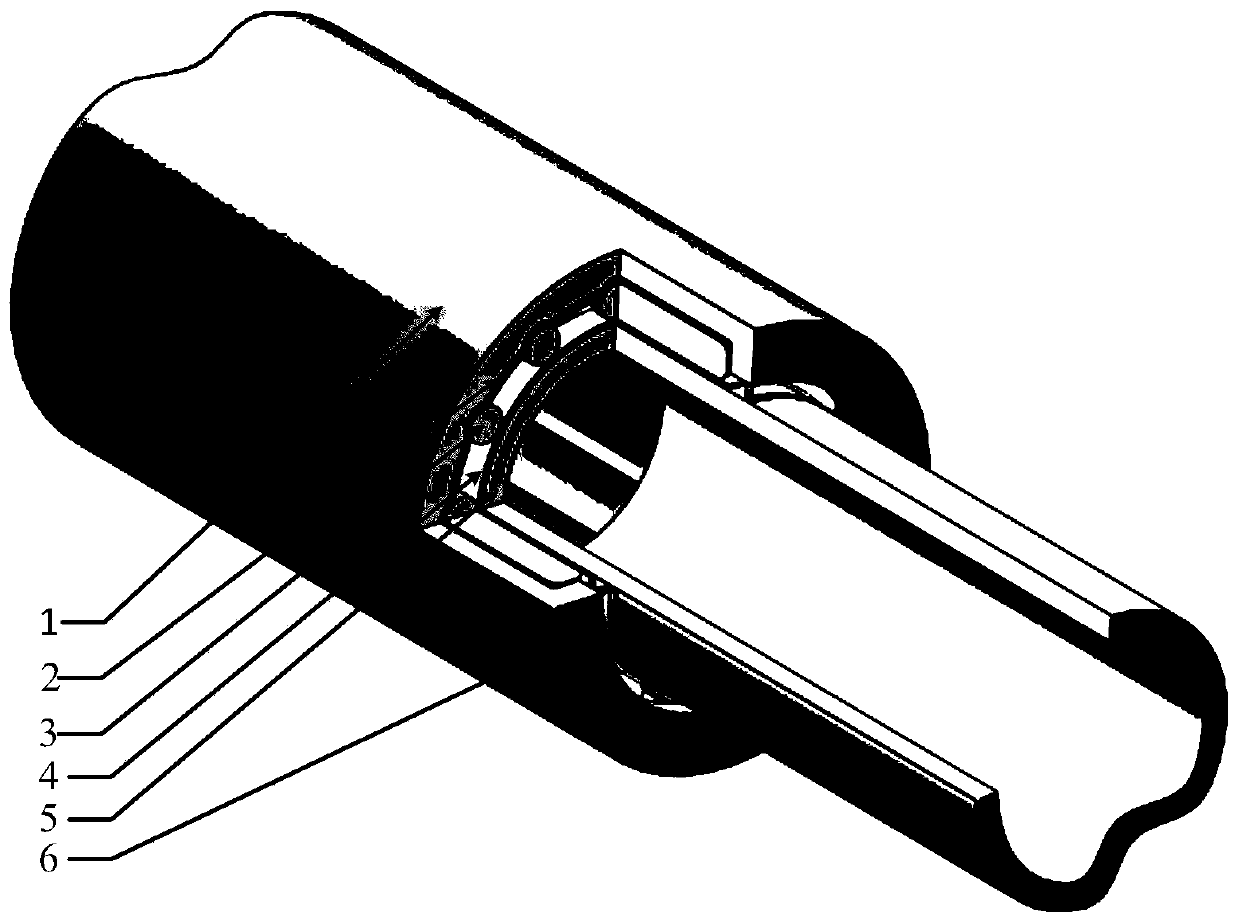

[0023] Aiming at the problem of excessive contact resistance and high loss of the existing conductive rotary joint, a new conductive rotary joint structure is designed to improve the efficiency of power transmission.

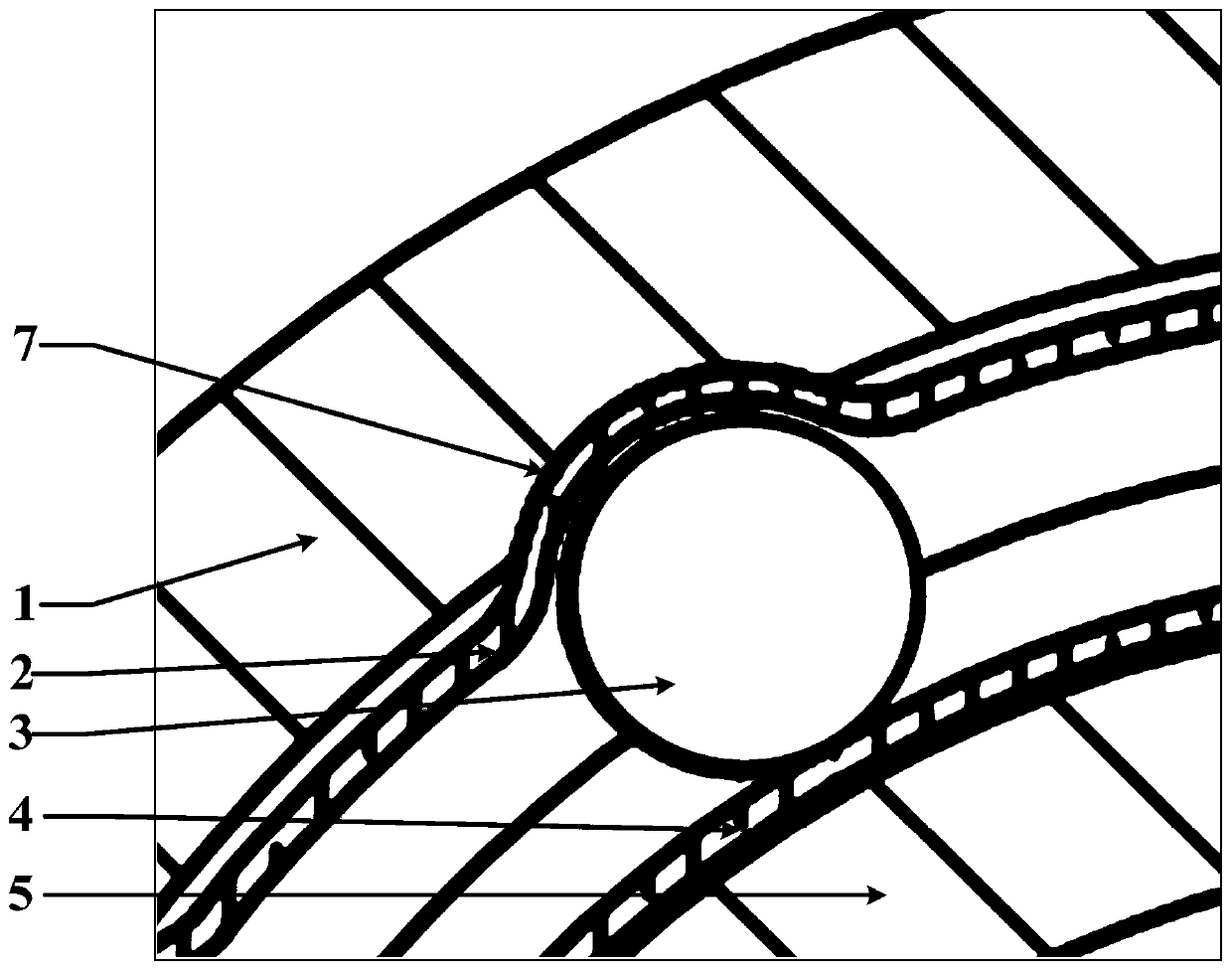

[0024] like Figure 1-3 As shown, the present invention provides a high-current conductive rotary joint for power transmission of solar arrays, which consists of three parts: an inner conductive shaft 5, an outer conductive shaft 1, and a rolling and rotating structure. The rolling and rotating structure consists of 2 and 12 contact shrapnels. The conductive needle roller 3 and the electrical contact ring 4 constitute. The inner wall of the outer conductive shaft 1 is provided with a groove 7, and is attached with a contact shrapnel 2. The electrical contact ring 4 is a ring structure coaxial with the inner conductive shaft 5, and is completely attached to the surface of the inner conductive shaft. The conductive roller 3 It is arranged between the groove part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com