Novel three-DOF (degree of freedom) permanent magnet type bearing-free motor

A bearingless motor, degree-of-freedom technology, applied in magnetic circuits, electromechanical devices, electrical components, etc. characterized by magnetic materials, can solve the problems of reducing critical speed and power density, increasing the axial length of the suspension motor system, etc. Simple control, reduced axial length, system volume and weight, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

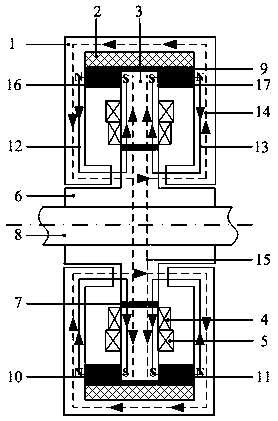

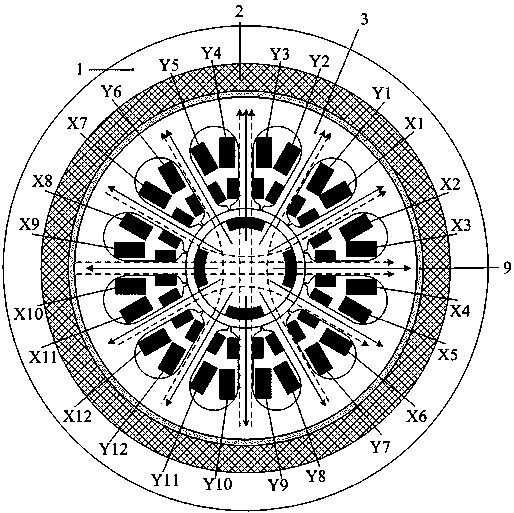

[0015] like figure 1 A new three-degree-of-freedom permanent-magnet bearingless motor shown includes a rotor and a stator. The rotor is composed of a rotating shaft 8 and a rotor core 6 , and rotor permanent magnets 7 are embedded on the surface of the rotor core 6 .

[0016] The stator includes a stator core 3 sequentially connected radially outward along the rotor core 6, an outer magnetic isolation ring 9, an annular axial suspension winding 2, and axial windings symmetrically arranged on the left and right sides of the stator core 3. The control core 1, the left stator permanent magnet ring 10, and the right stator permanent magnet ring 11, the axial control core 1 can be a disc-shaped, three-pole, four-pole or other magnetic pole structure, and the axial control core 1 in this embodiment is a circle disc shape; the outer edge of the axial control core 1 is butted, and the inner edges on the left and right sides respectively extend to the rotor core 6 and are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com