Alternating current servo driver system and control method

A technology of AC servo and control method, applied in the direction of starting device, etc., can solve the problems of difficult structure, not intuitive enough, and not high enough control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

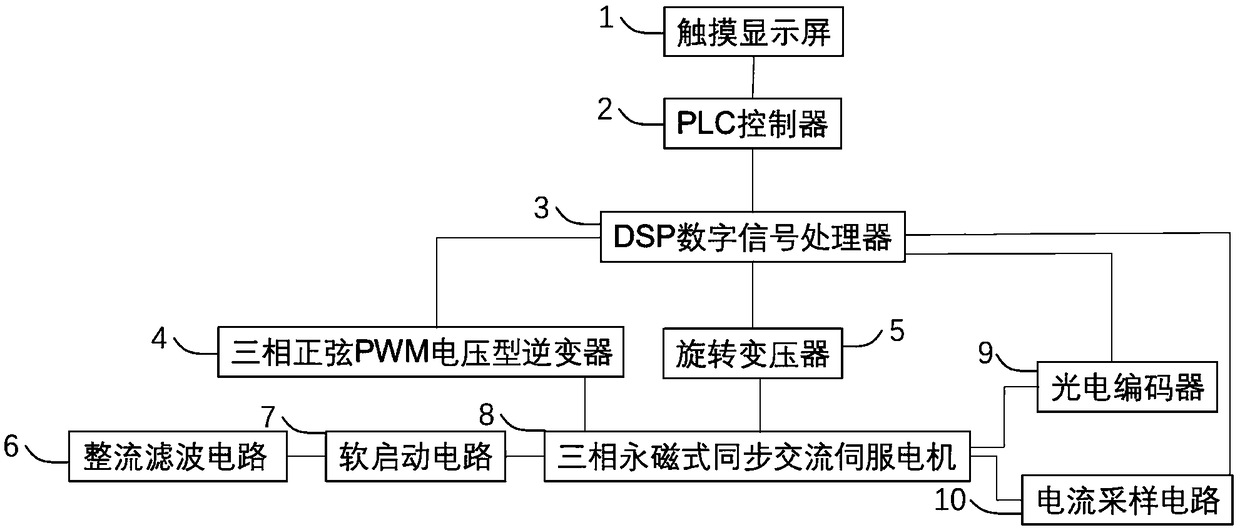

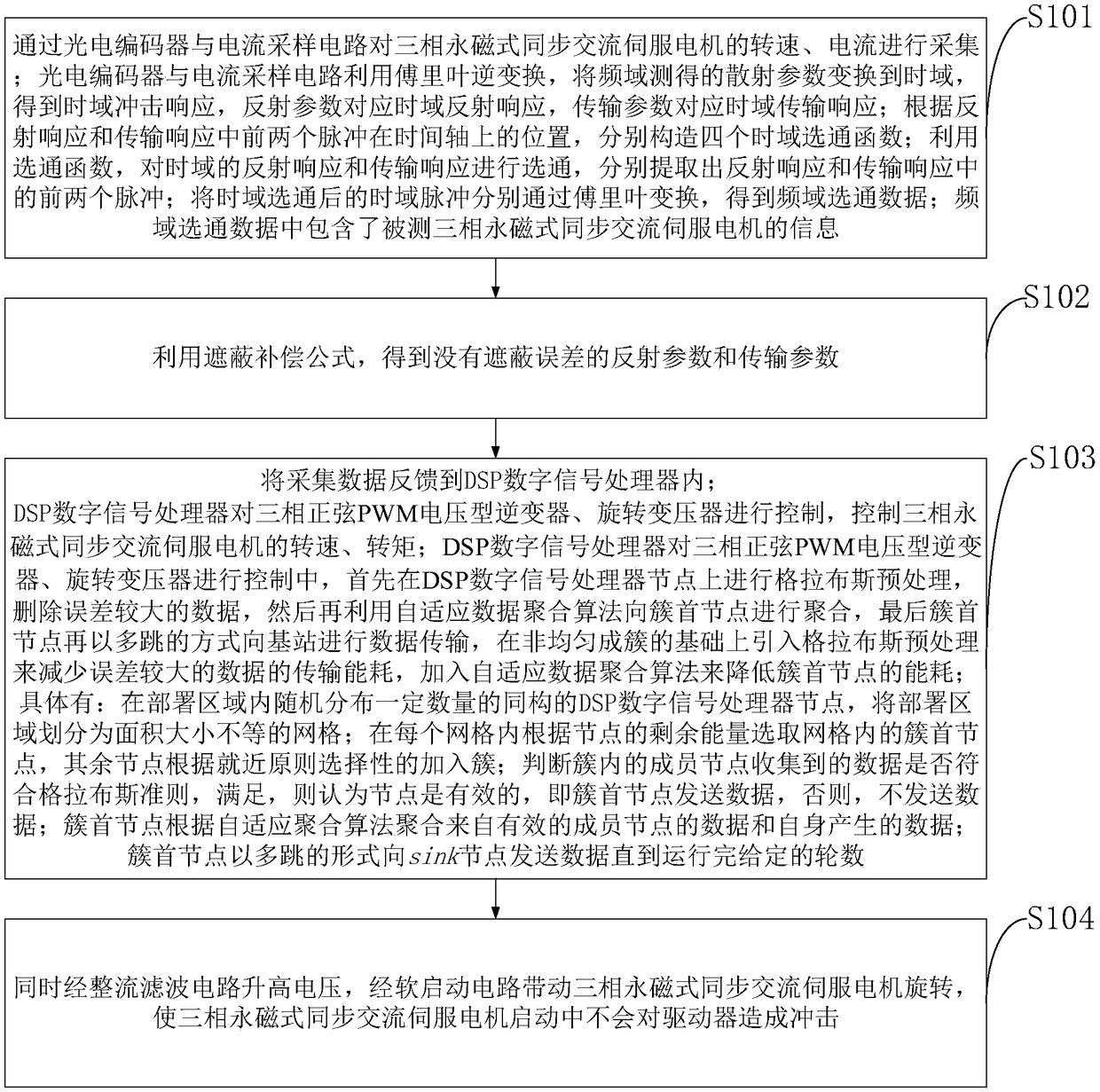

[0079] Such as figure 1 , figure 2 As shown, the AC servo driver system provided by the embodiment of the present invention includes: a touch display screen 1, a PLC controller 2, a DSP digital signal processor 3, a three-phase sinusoidal PWM voltage type inverter 4, a resolver 5, a rectification filter Circuit 6, soft start circuit 7, three-phase permanent magnet synchronous AC servo motor 8, photoelectric encoder 9, current acquisition circuit 10.

[0080] The DSP digital signal processor 3 is connected to the three-phase sinusoidal PWM voltage type inverter 4 and the rotary transformer 5 through wires, and the three-phase sinusoidal PWM voltage type inverter 4 and the rotary transformer 5 are connected to the three-phase permanent magnet type inverter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com