Automatic dispensing and curing system for silicon rod and automatic dispensing and curing method

A technology of automatic dispensing and curing method, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of high labor costs, skewed silicon wafers, and low production efficiency of silicon wafers, saving labor costs and avoiding damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

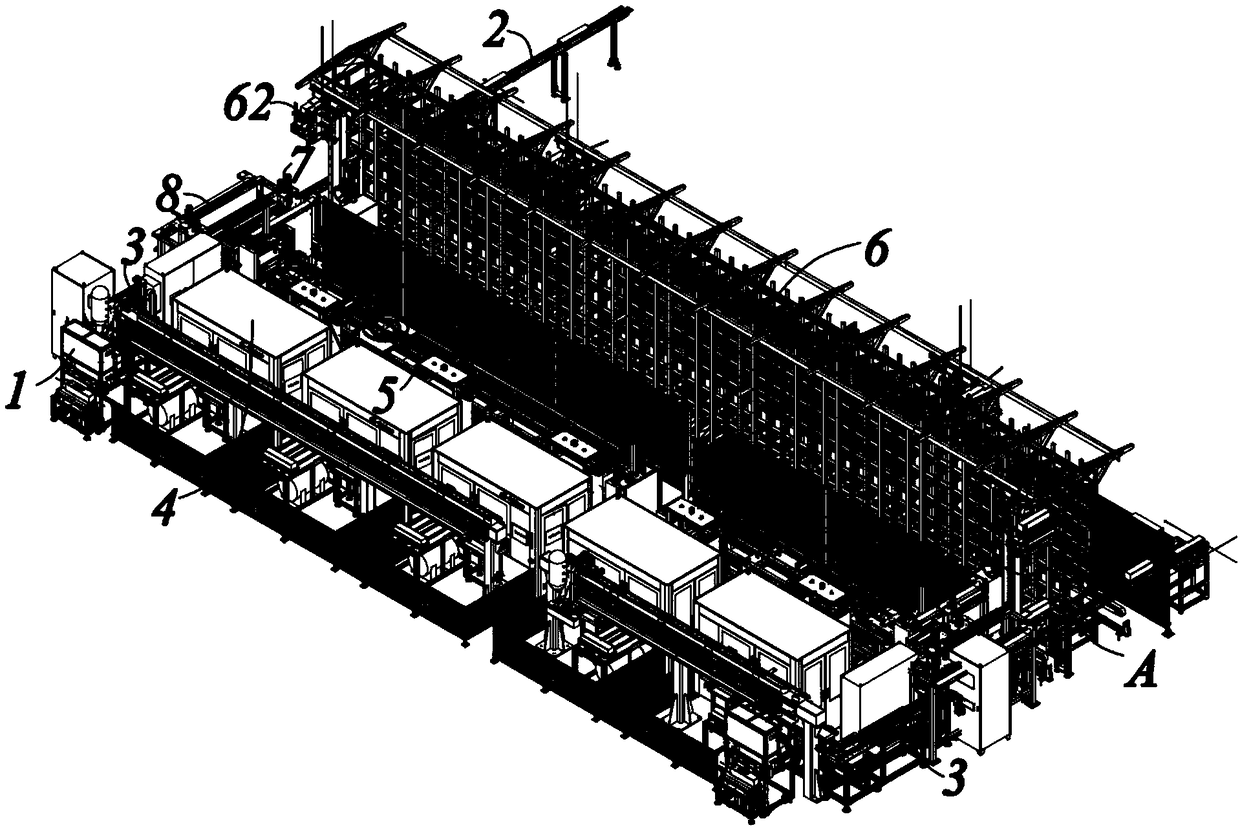

[0029] The present invention will be described in detail below in conjunction with various embodiments shown in the accompanying drawings, please refer to Figure 1 to Figure 5 Shown is a preferred embodiment of the present invention.

[0030] The present invention provides an automatic dispensing and curing system 100 for silicon rods, which is used to realize the fully automated production of silicon wafers, thereby reducing labor costs and avoiding damage to newly produced silicon wafers due to human operations during the production process. cause loss.

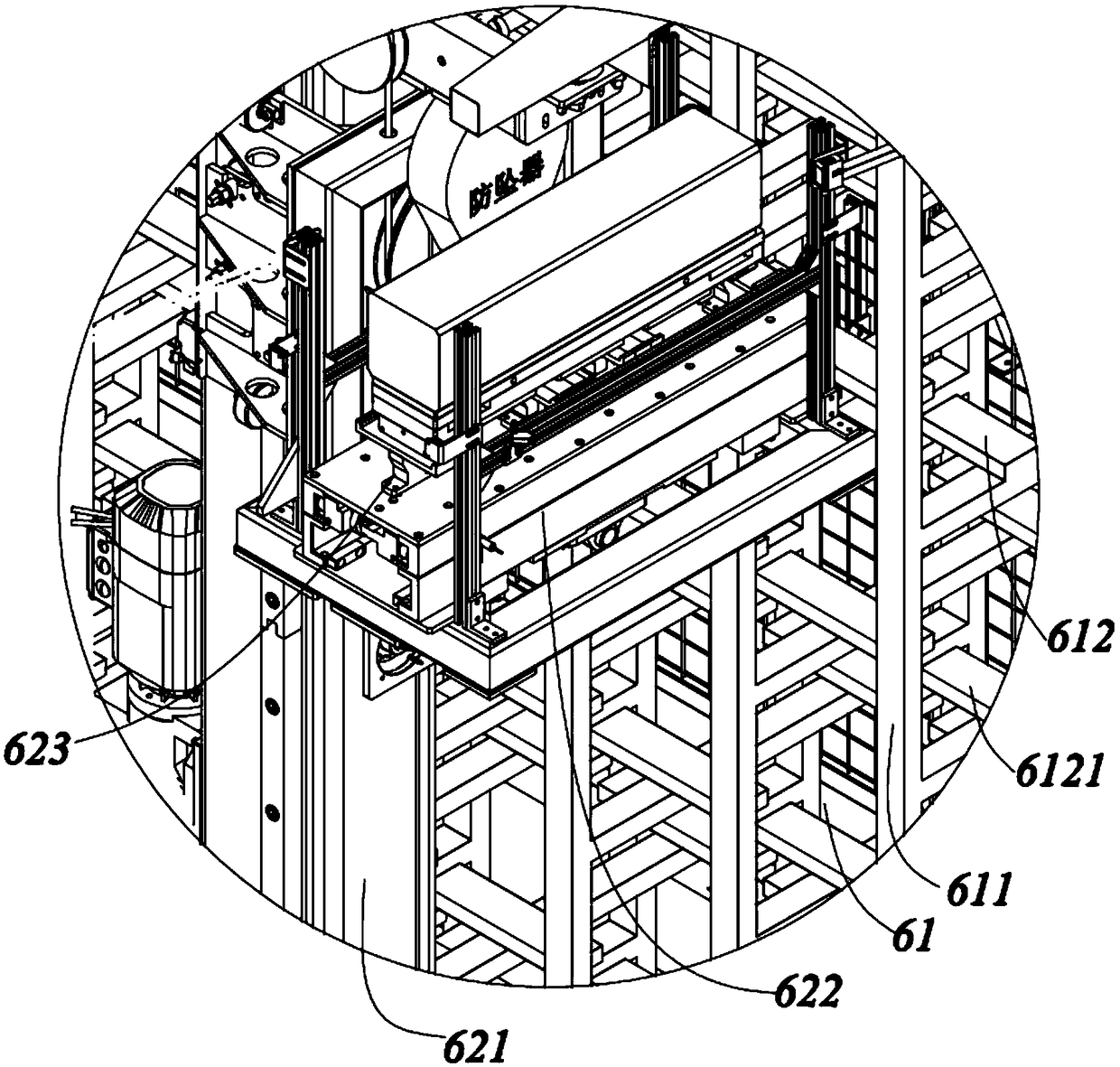

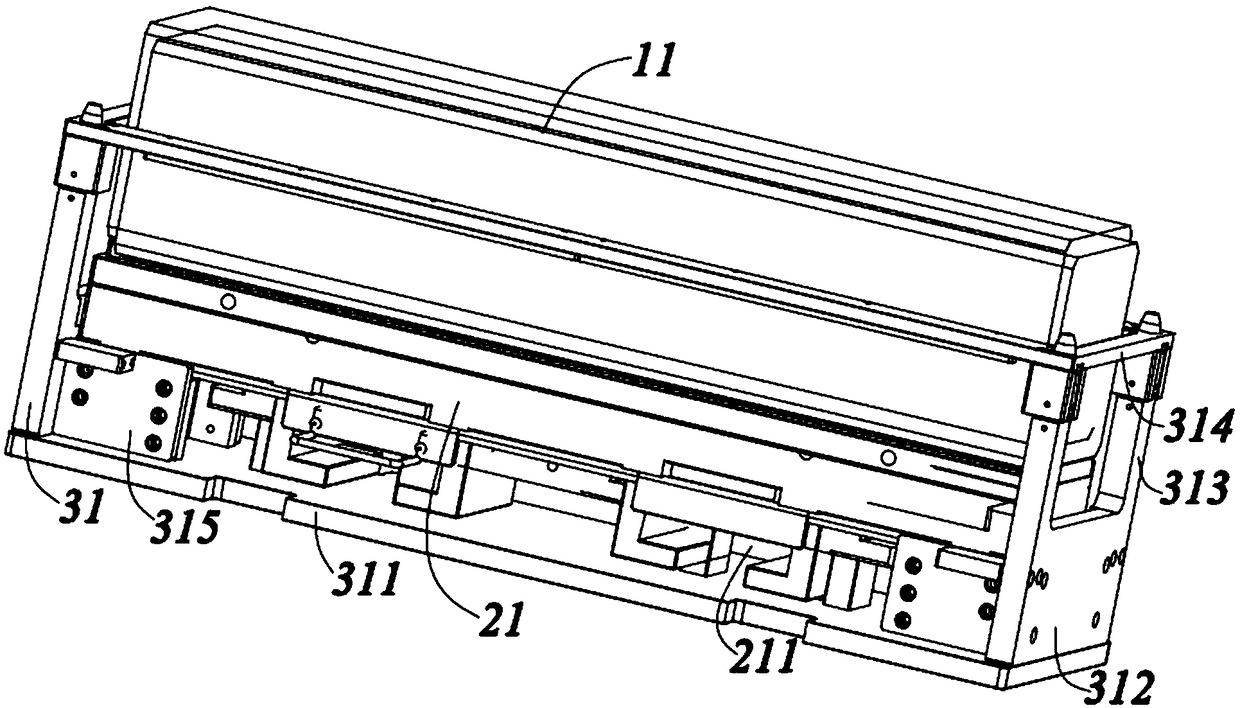

[0031] The automatic dispensing and curing system 100 for silicon rods includes a silicon rod body feeding device 1 providing a silicon rod body 11, a substrate feeding device 2 providing a substrate 21, a fixing fixture feeding device 3 providing a fixing fixture 31, and The substrate 21 and the silicon rod body 11 that are positioned in the fixing fixture 31 are bonded together to form the dispensing chamber 4 of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com