Punching machine for machining automobile parts

A technology of auto parts and stamping machines, applied in the field of stamping machines, can solve the problems of stamping machines that are easy to hurt the staff, hidden safety hazards, and positional deviation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

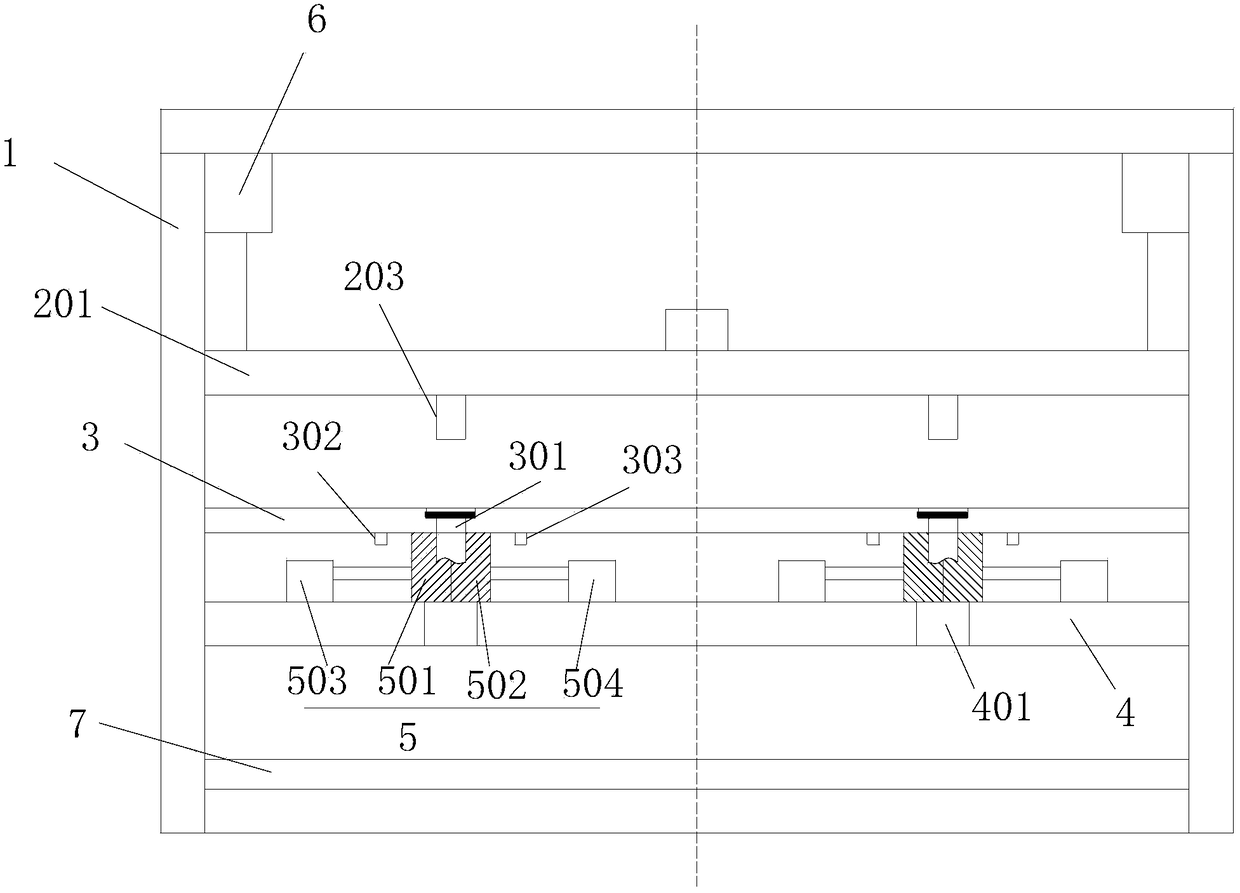

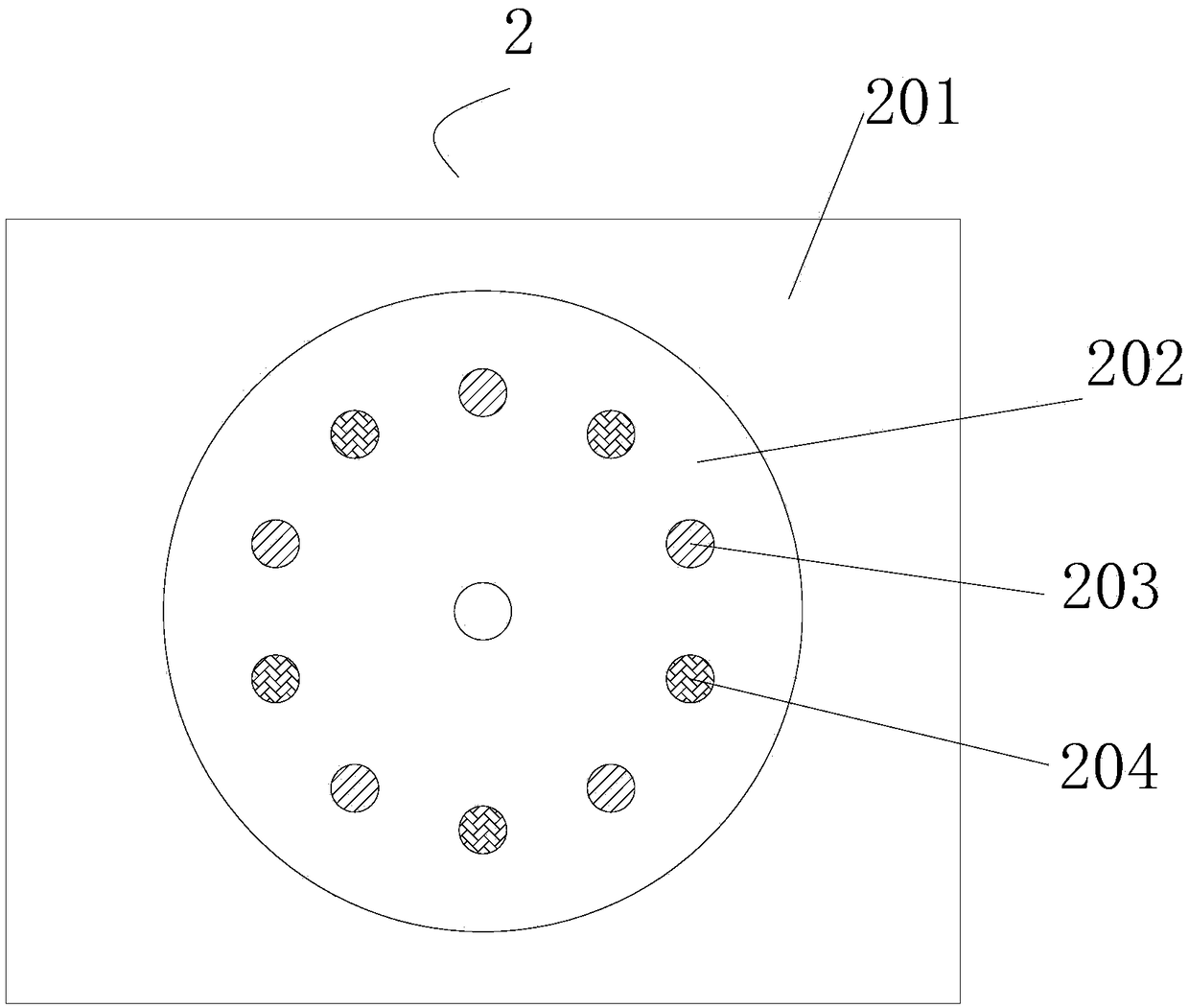

[0016] Such as Figure 1-Figure 2 as shown, figure 1 It is a structural schematic diagram of a stamping machine for processing auto parts proposed by the present invention; figure 2 It is a structural schematic diagram of a die base in a stamping machine for processing auto parts proposed by the present invention.

[0017] refer to Figure 1-Figure 2 , a stamping machine for processing auto parts proposed by the present invention, including a frame 1, a mold frame 2, a guide plate 3, a blanking plate 4, N forming dies 5, a first driving mechanism 6 and a transmission mechanism 7 , N is a positive integer; where:

[0018] The mold frame 2 includes a mold frame 201, a template 202, N cutting punches 203, N forming punches 204 and a second drive mechanism 205, the mold frame 201 is arranged horizontally, and the mold frame 201 is movably installed on the frame 1 and is controlled by The first drive mechanism 6 is driven to move up and down in the vertical direction. The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com