Methods for welding austenitic alloy steel and preparing non-magnetic drill collar by utilizing linear friction welding technology

A linear friction welding and linear friction welding technology, which is applied in the direction of welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problems of difficult repair of failed drill collars, low production efficiency, waste of materials, etc., and achieve mechanical properties Excellent, stable welding quality, and the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

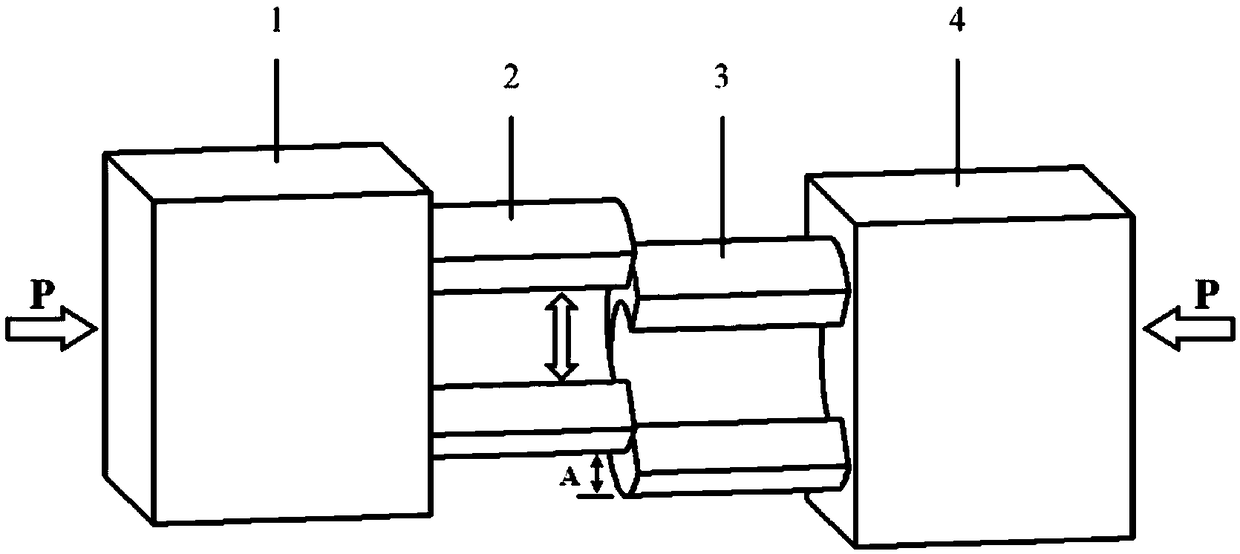

[0051] Such as figure 2 , 3 Shown, a kind of linear friction welding process prepares the method for non-magnetic drill collar, comprises the steps:

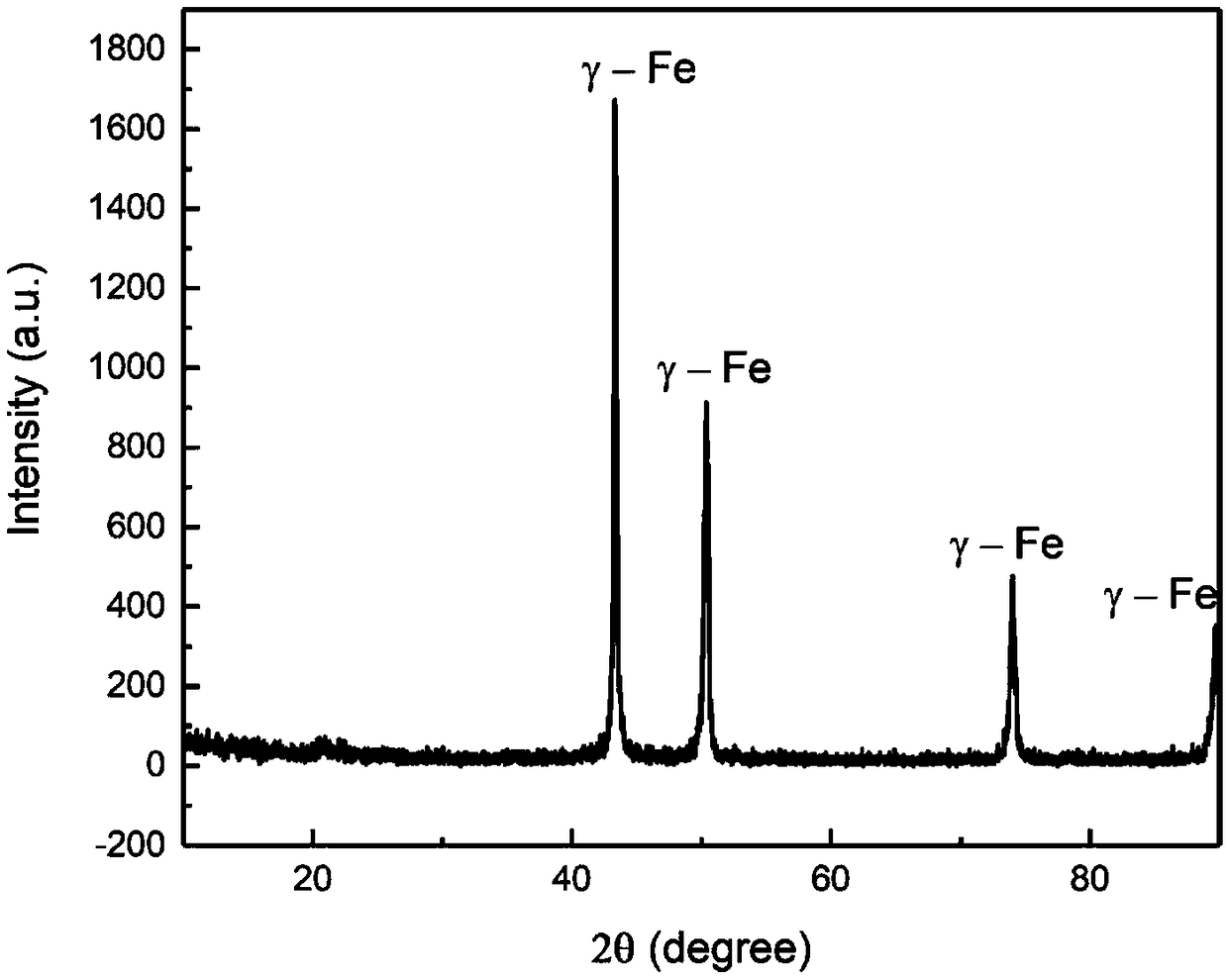

[0052] (1) Welding interface treatment: Austenitic alloy steel (composition as shown in Table 1) is made into a workpiece with an outer diameter of φ104.8mm, a wall thickness of 20mm, and a length of 300mm, and the oxide skin on the interface of the workpiece to be welded is cleaned with sandpaper At the same time, use alcohol and acetone to remove oil stains on the interface to be welded;

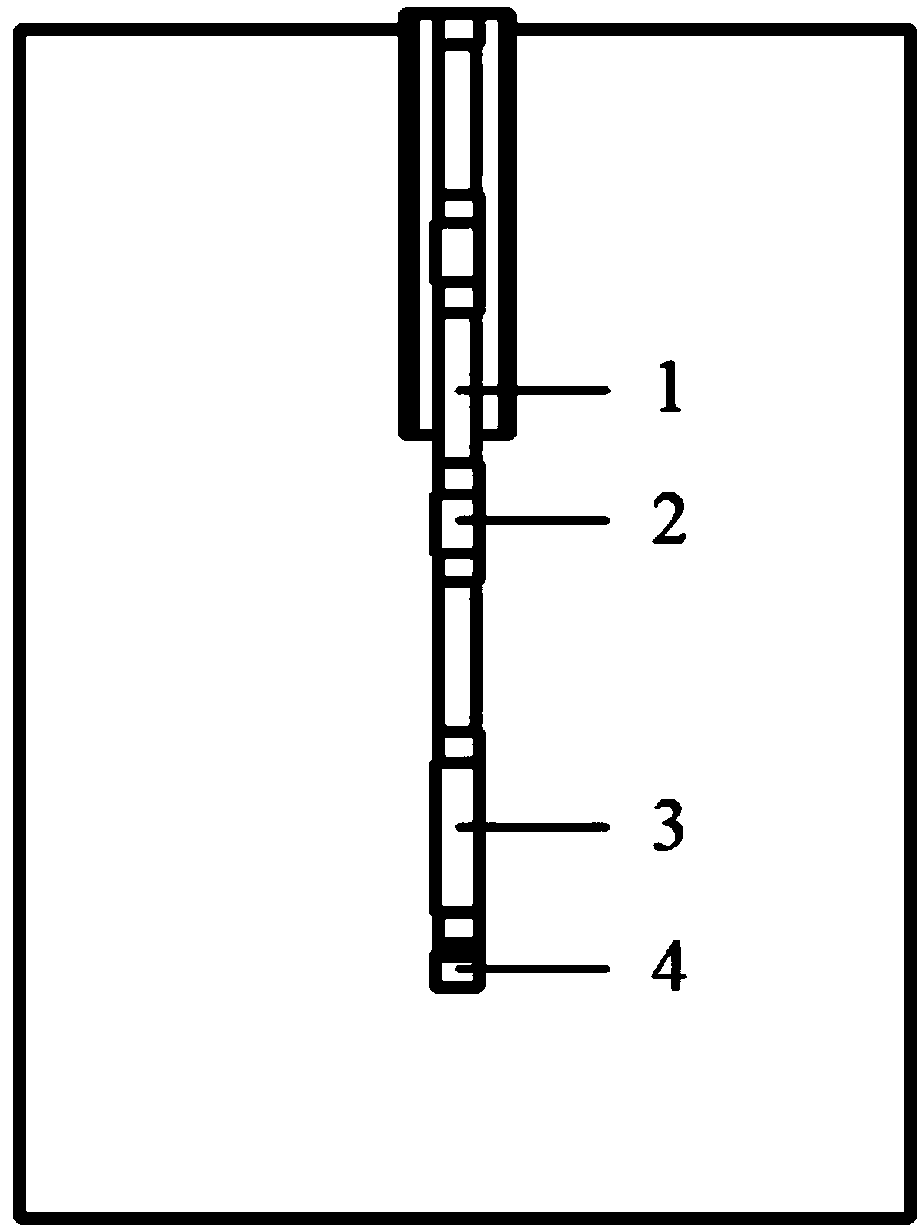

[0053] (2) Welding clamping: install the workpiece in step (1) into the HWI-LFW-30 linear friction welding machine, and clamp a workpiece in the movable end fixture 4 and the vibration end fixture 1 of the welding machine (workpiece 2 at the vibration end, workpiece 3 at the mobile end), and ensure that workpieces 2 and 3 are coaxial with the fixture at the vibration end and the fixture at the mobile end; set the vibration frequency of th...

Embodiment 2

[0056] The preparation method is the same as that in Example 1, the difference is that the workpiece has an outer diameter of φ228.6 mm, a wall thickness of 80 mm, and a length of 300 mm. The vibration frequency of the workpiece at the vibrating end is 200 Hz, the amplitude is 5 mm, the friction pressure is 300 MPa, and the upsetting pressure is 200 Hz. It is 600MPa, the friction time is 15s, and the holding time is 30s.

Embodiment 3

[0058] The preparation method is the same as in Example 1, except that the vibration frequency of the workpiece at the vibrating end is 5 Hz, the amplitude is 4 mm, the friction pressure is 300 MPa, the upsetting pressure is 500 MPa, the friction time is 5 s, and the pressure holding time is 5 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com