Automatic expansion nail inserting equipment

An expansion nail and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of uneven quality of finished products, time-consuming and laborious, and achieve the effect of output quality assurance, avoiding damage, and releasing human labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

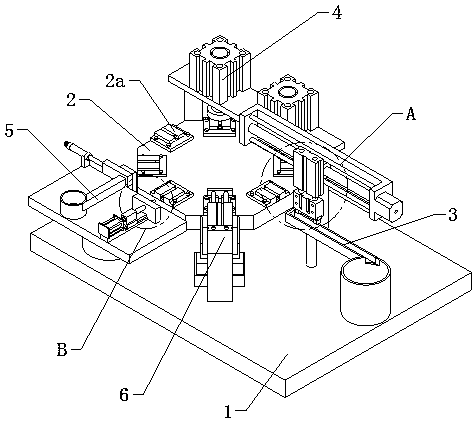

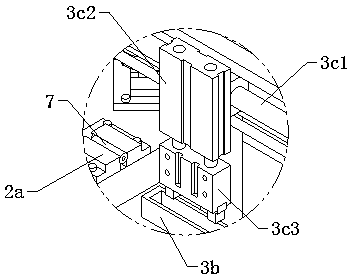

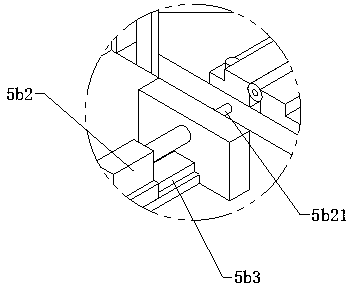

[0026] refer to Figure 1 to Figure 10 The automatic nail insertion equipment for expansion nails shown includes a workbench 1, a multi-station turntable 2 set in the middle of the workbench 1, an expansion tube feeding device 3, a pressing device 4, a screw feeding device 5 and a feeding device 6 , the expansion tube feeding device 3, the screw feeding device 5, the pressing device 4 and the unloading device 6 are all arranged on the workbench 1 and arranged around the multi-station turntable 2 in turn, and on the multi-station turntable 2 A plurality of expansion nail fixtures 2a are provided, and the expansion nail fixtures 2a are located around the multi-station turntable 2, and the expansion nail fixtures 2a are equidistantly arranged, and the expansion tube feeding device 3 includes a first vibrating plate 3a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com