Method for removing chlorine from metallurgical slag

A technology for removing chlorine from metallurgical slag is applied in the fields of environmental protection and comprehensive utilization of resources, which can solve the problems of low dechlorination efficiency, instability and stability, and achieve the effects of high dechlorination efficiency, low cost and good working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

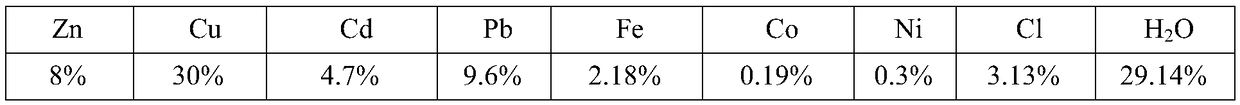

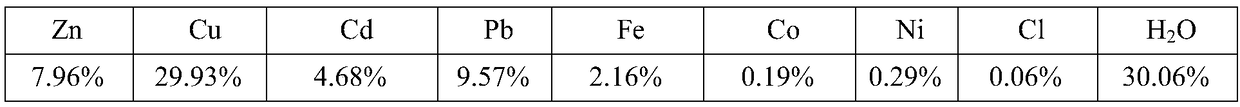

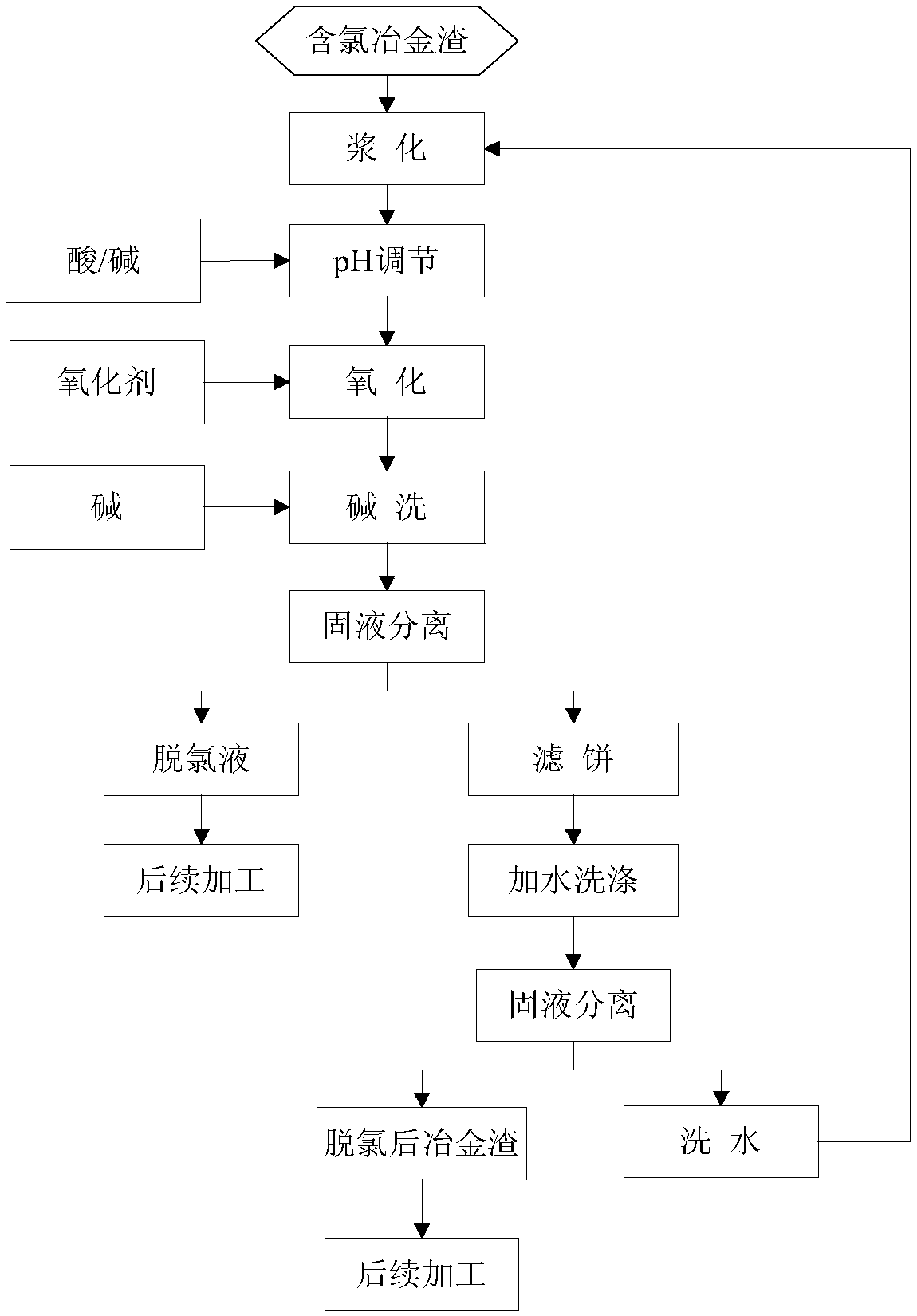

[0030] Such as Figure 1-3 As shown, the present invention provides the following technical solutions: a method for removing chlorine in metallurgical slag, characterized in that it comprises the following manufacturing steps:

[0031] S1: pulping chlorine-containing metallurgical slag with water;

[0032] S2: adjusting the pH of the slurry solution;

[0033] S3: Dosing an oxidizing agent to oxidize insoluble substances such as cuprous chloride in the slag;

[0034] S4: Dosing alkali, bringing the chlorine in the slag into the solution in the form of salt, and at the same time precipitating valuable metals in the solution into the slag;

[0035] S5: performing liquid-solid separation;

[0036] S6: washing the filter residue to obtain dechlorinated metallurgical slag and salty wastewater.

[0037] In the S1 step, the liquid-solid ratio of the chlorine-containing metallurgical slag slurry is 1-8:1, the slurry of the chlorine-containing metallurgical slag is completed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com