A kind of high strength and toughness al-zn-mg-cu series aluminum alloy and heat treatment method thereof

A heat treatment method and aluminum alloy technology, which is applied in the field of high strength and toughness Al-Zn-Mg-Cu aluminum alloy and its heat treatment field, can solve the problems of poor stress corrosion resistance, long heat treatment time, insufficient alloy strength, etc., and reduce quenching Sensitivity, Enhanced Overall Performance, Enhanced Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

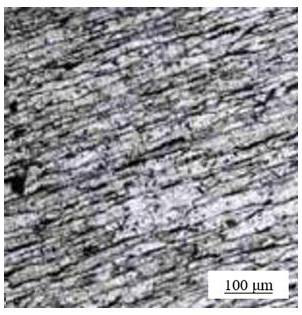

Image

Examples

Embodiment 1

[0054] The composition (by mass percentage) of the high strength and toughness Al-Zn-Mg-Cu aluminum alloy of this embodiment is: Zn: 7.5%, Mg: 1.2%, Cu: 2.0%, Si: 0.02%, Fe: 0.04% , Cr: 0.04%, Ti: 0.02%, Er: 0.1%, Sn: 0.10%, Zr: 0.2%, Ag: 0.2%, Mn: 0.02%, Sc: 0.4%, Y: 0.5%, Yb: 0.25% , Ce: 0.1%, Hf: 0.15%, Ca: 0.01%, V: 0.12%, La: 0.08%, and the balance is Al.

[0055] The high-strength and toughness Al-Zn-Mg-Cu aluminum alloy of the present invention is made into products through smelting, refining, casting, homogenization treatment, hot rolling and heat treatment, wherein the specific steps of the heat treatment process are:

[0056] (1) Two-stage homogenization treatment:

[0057] Put the alloy ingot obtained through smelting, refining and casting into a salt bath furnace, heat up at a heating rate of 2°C / min, and mill the surface after two-stage homogenization treatment at 425°C×24h+465°C×36h, and then Hot rolled to 150mm thick alloy plate;

[0058] (2) Two-stage solid ...

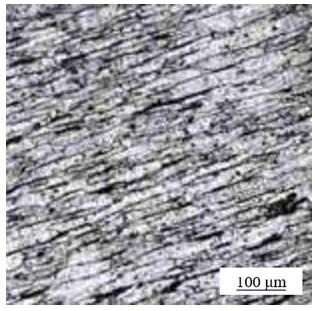

Embodiment 2

[0065] The composition (by mass percentage) of the high strength and toughness Al-Zn-Mg-Cu series aluminum alloy of this example is: Zn: 8.0%, Mg: 1.6%, Cu: 2.2%, Si: 0.03%, Fe: 0.05%, Cr: 0.04%, Ti: 0.03%, Er: 0.15%, Sn: 0.12%, Zr: 0.22%, Ag: 0.25%, Mn: 0.04%, Sc: 0.5%, Y: 0.7%, Yb: 0.28%, Ce: 0.15%, Hf: 0.2%, Ca: 0.02%, V: 0.2%, La: 0.1%, and the balance is Al.

[0066] The high-strength and toughness Al-Zn-Mg-Cu aluminum alloy of the present invention is made into products through smelting, refining, casting, homogenization treatment, hot rolling and heat treatment, wherein the specific steps of the heat treatment process are:

[0067] (1) Two-stage homogenization treatment:

[0068] Put the alloy ingots obtained through smelting, refining and casting into a salt bath furnace, heat up at a heating rate of 3°C / min, and mill the surface after two-stage homogenization treatment at 425°C×24h+465°C×36h, and then Hot rolled to 170mm thick alloy plate;

[0069] (2) Two-stage so...

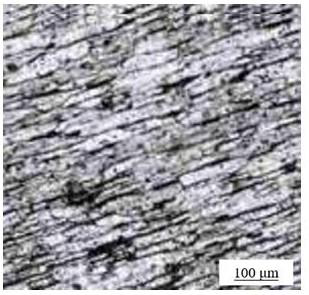

Embodiment 3

[0076] The composition (by mass percentage) of the high-strength and toughness Al-Zn-Mg-Cu aluminum alloy of this example is: Zn: 8.5%, Mg: 2.0%, Cu: 2.5%, Si: 0.04%, Fe: 0.06% , Cr: 0.04%, Ti: 0.05%, Er: 0.25%, Sn: 0.15%, Zr: 0.25%, Ag: 0.3%, Mn: 0.06%, Sc: 0.6%, Y: 1.0%, Yb: 0.3% , Ce: 0.2%, Hf: 0.25%, Ca: 0.03%, V: 0.25%, La: 0.15%, and the balance is Al.

[0077] The high-strength and toughness Al-Zn-Mg-Cu aluminum alloy of the present invention is made into products through smelting, refining, casting, homogenization treatment, hot rolling and heat treatment, wherein the specific steps of the heat treatment process are:

[0078] (1) Two-stage homogenization treatment:

[0079] Put the alloy ingots obtained through smelting, refining and casting into a salt bath furnace, heat up at a heating rate of 4°C / min, and mill the surface after two-stage homogenization treatment at 425°C×24h+465°C×36h, and then Hot-rolled to 200mm thick alloy plate;

[0080] (2) Two-stage solid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com