Steel mesh edge rubber waterstop with self-adhesive layer and manufacturing process thereof

A rubber waterstop and manufacturing process technology, applied in building structures, building components, building thermal insulation materials, etc. Erosion and other problems, to achieve the effect of improving the corrosion resistance of various chemical media, improving the bonding strength and enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

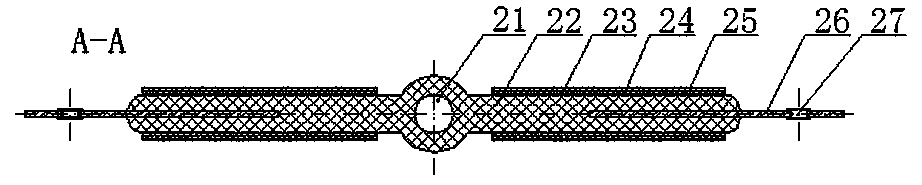

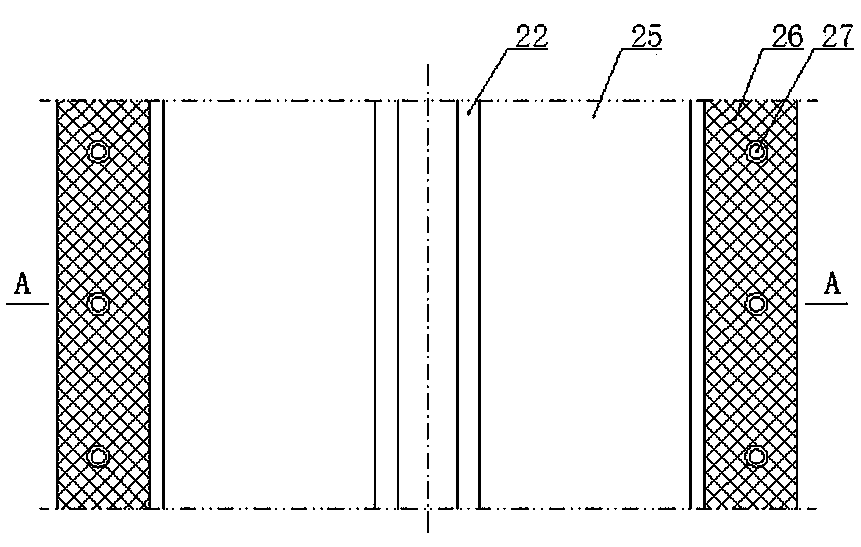

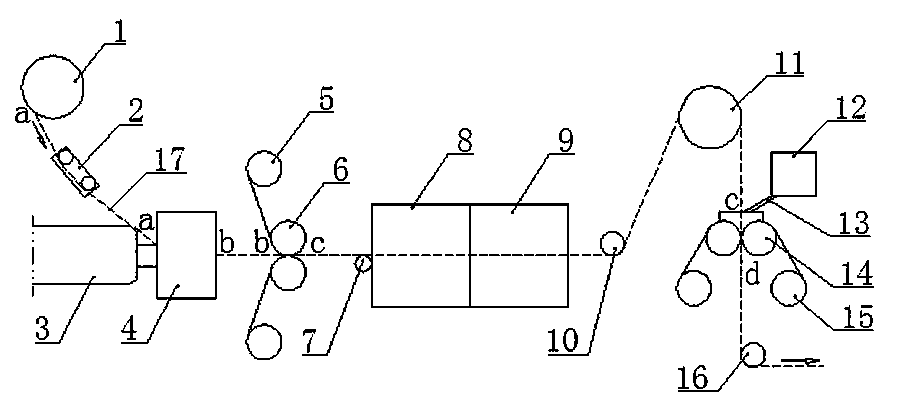

[0036] see figure 1 and figure 2 , the present invention is a steel mesh side rubber waterstop with a self-adhesive layer, including a rubber main body 22, a round hole 21 is provided in the middle to meet the expansion and contraction of the building deformation joint, and the rubber main body is on both sides of the round hole 21 wing panels. A steel mesh edge 26 is compounded in the middle of both sides of the wing plate, a fiber interface reinforcement layer 23 is compounded on the surface of the wing plate, and a synthetic rubber self-adhesive layer 24 is coated on the surface of the fiber interface reinforcement layer 23. The synthetic rubber self-adhesive layer is covered with release paper (film) 25.

[0037] The rubber main body 22 includes EPDM rubber (EPDM), natural rubber, chlorinated polyethylene and auxiliary materials, and its basic formula is (parts by weight): EPDM rubber 60, natural rubber 40, chlorinated polyethylene Ethylene 100, carbon black 4, zinc ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com