A coal blending cost optimization method, equipment and storage equipment

A cost optimization and coal blending technology, applied in data processing applications, forecasting, instruments, etc., can solve problems such as difficulty in obtaining optimal cost and coal blending schemes, and numerous constraints, so as to reduce coal blending costs and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0047] Embodiments of the present invention provide a coal blending cost optimization method, equipment and storage equipment.

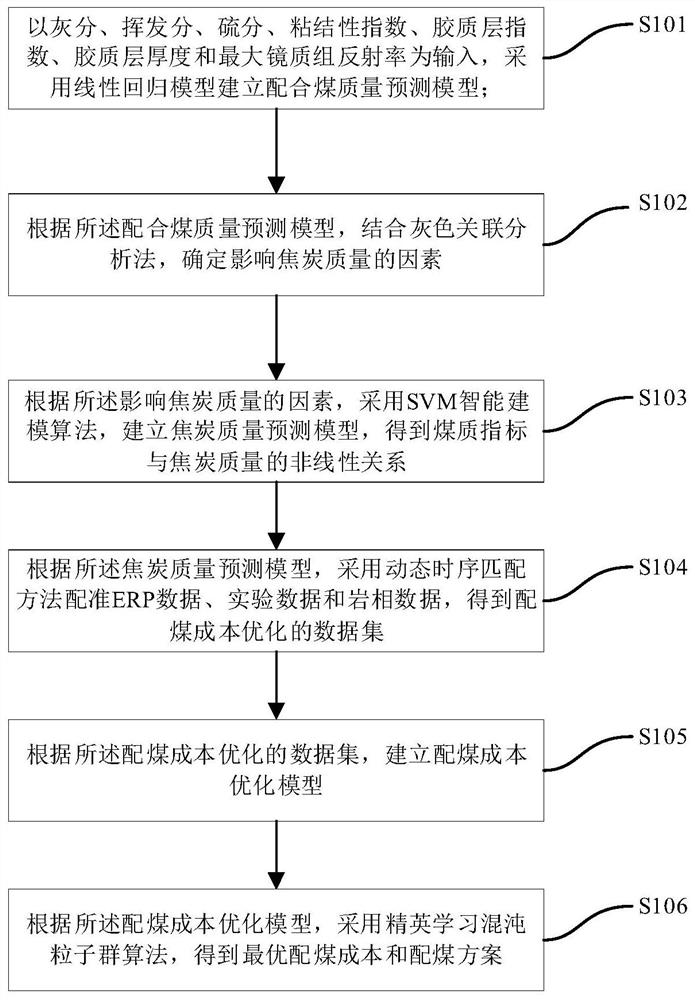

[0048] Please refer to figure 1 , figure 1 It is a flowchart of a coal blending cost optimization method in an embodiment of the present invention, specifically including the following steps:

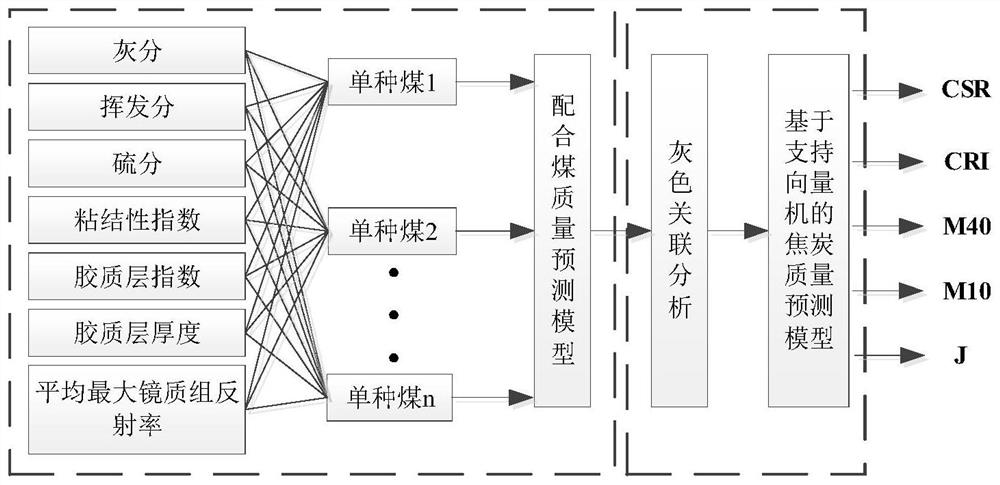

[0049] S101: by ash content A d , Volatile V daf , sulfur S td , cohesion index G, colloidal layer index X, colloidal layer thickness Y and maximum vitrinite reflectance R max As input, a linear regression model is used to establish a coal quality prediction model;

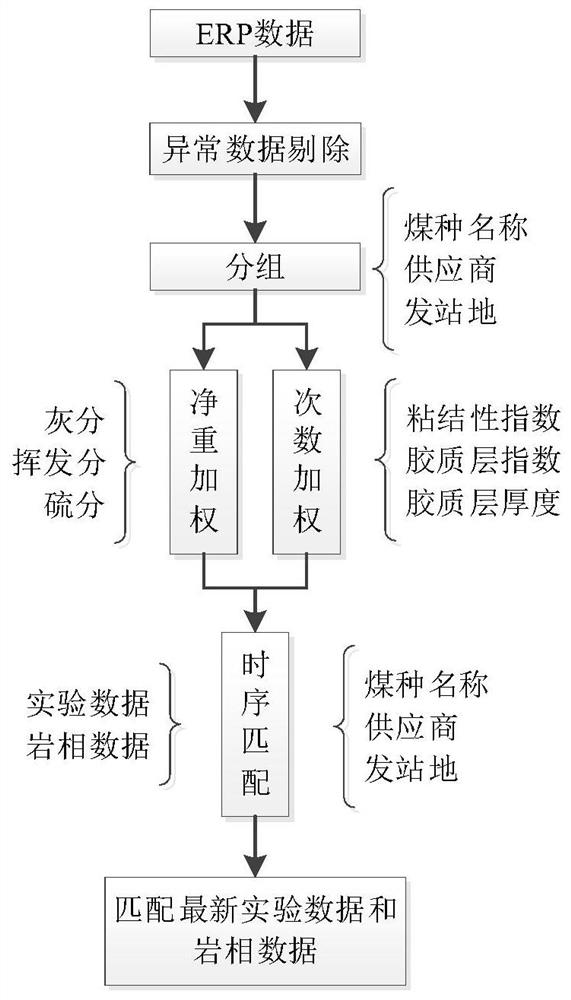

[0050] S102: According to the blending coal quality prediction model, determine the factors that affect the coke quality by using th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com