Preparation method and application of compound foam fire extinguishing agent

A technology of foam fire extinguishing agent and foaming agent, which is applied in the field of preparation of synthetic foam fire extinguishing agent, can solve the problems of synthetic foam fire extinguishing agent such as high freezing point, poor thermal stability and anti-burning performance, complex production process, etc., and achieve melting performance Good, broaden the scope of use, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

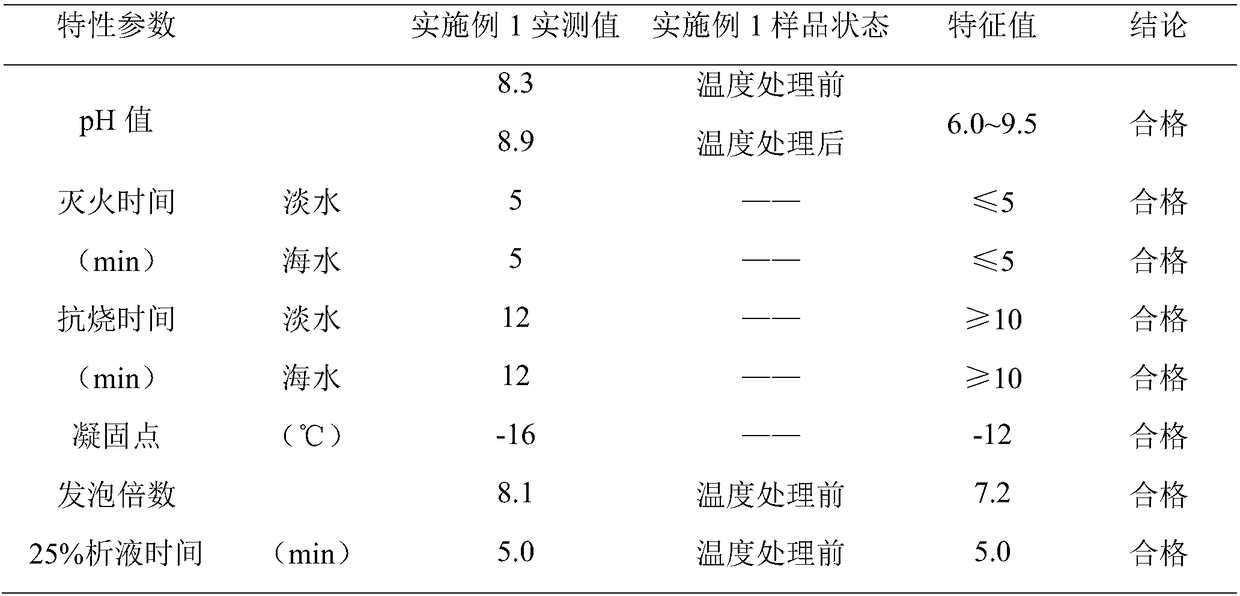

Embodiment 1

[0024] (1) Prepare synthetic foam fire extinguishing agent:

[0025] Add ionized water (500kg), imidazoline (60kg), sodium perfluorononenyloxybenzenesulfonate (40kg), alkyl glycoside APG1012 (250kg), and urea (150kg) into a stirring tank, and stir and react at room temperature for 2 hours , to obtain the reaction solution;

[0026] Among them, imidazoline is a surfactant with extremely low toxicity, good foamability, excellent emulsifying properties and good biodegradability; sodium perfluorononenyloxybenzenesulfonate is a fluorocarbon surfactant, which has High surface activity and high heat resistance stability make the formed foam more stable; Alkyl glycoside APG1012 is used as a foaming agent; urea is used as a stabilizer to stabilize the foam formed by the fire extinguishing agent and have better film-forming performance;

[0027] (2) Intermediate control:

[0028] The reaction solution obtained in step (1) is adjusted to a pH value of 8.5 by adding caustic soda or pota...

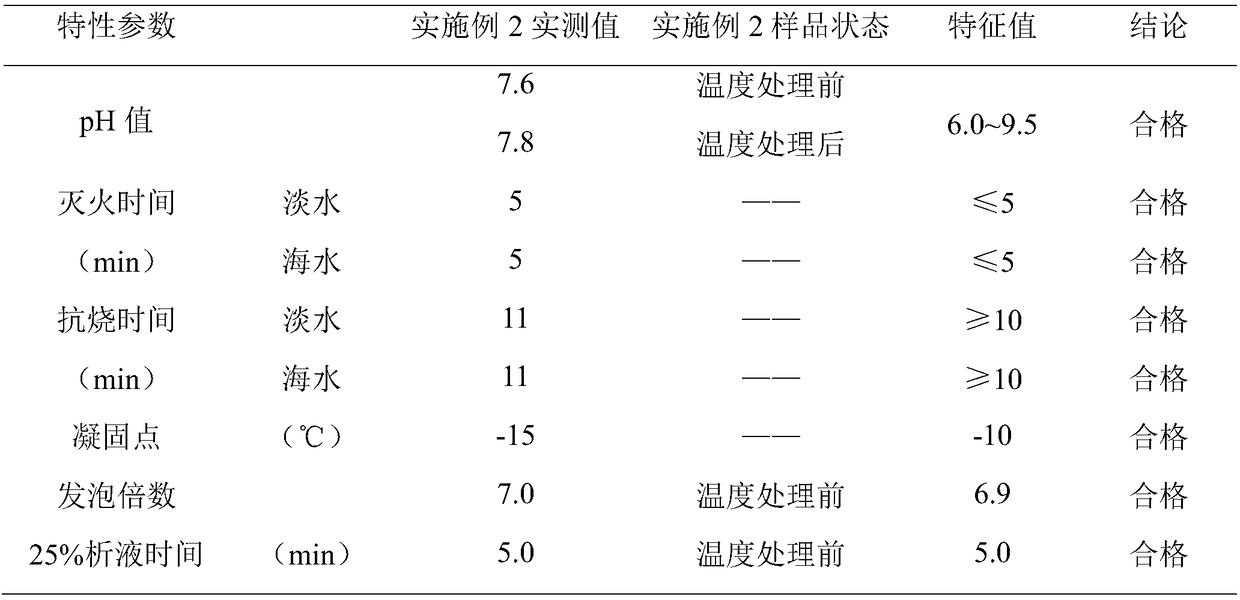

Embodiment 2

[0042] (1) Prepare synthetic foam fire extinguishing agent:

[0043] Add ionized water (690kg), imidazoline (40kg), sodium perfluorononenyloxybenzenesulfonate (20kg), alkyl glycoside APG1214 (150kg), and urea (100kg) into a stirring tank, and stir and react at room temperature for 1h , to obtain the reaction solution;

[0044] Among them, imidazoline is a surfactant with extremely low toxicity, good foamability, excellent emulsifying properties and good biodegradability; sodium perfluorononenyloxybenzenesulfonate is a fluorocarbon surfactant, which has High surface activity and high heat resistance stability make the formed foam more stable; Alkyl glycoside APG1214 is used as a foaming agent; urea is used as a stabilizer to stabilize the foam formed by the fire extinguishing agent and have better film-forming performance;

[0045] (2) Intermediate control:

[0046] The reaction solution obtained in step (1) is adjusted to a pH value of 7.0 by adding caustic soda or potassium...

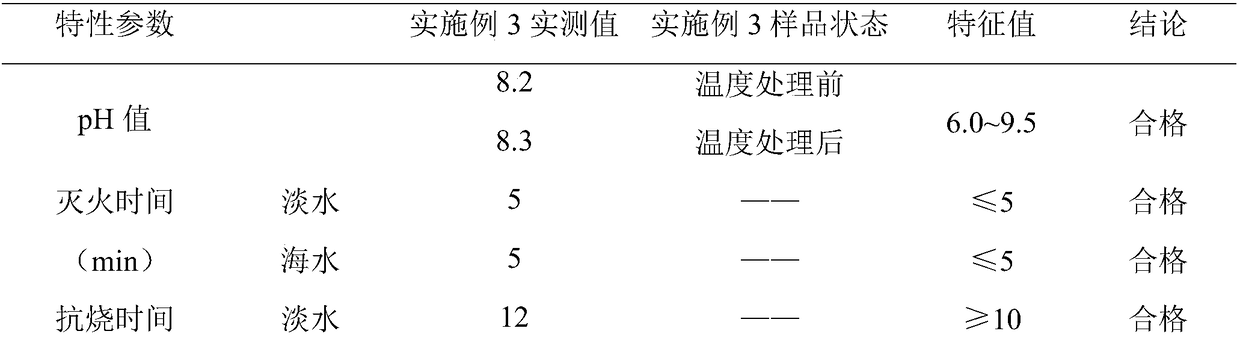

Embodiment 3

[0060] (1) Prepare synthetic foam fire extinguishing agent:

[0061] Add ionized water (600kg), imidazoline (50kg), sodium perfluorononenyloxybenzenesulfonate (30kg), alkyl glycoside APG1012 (200kg), urea (120kg) in the stirring tank, and stir the reaction at room temperature for 1.5 h, to obtain the reaction solution;

[0062] Among them, imidazoline is a surfactant with extremely low toxicity, good foamability, excellent emulsifying properties and good biodegradability; sodium perfluorononenyloxybenzenesulfonate is a fluorocarbon surfactant, which has High surface activity and high heat resistance stability make the formed foam more stable; Alkyl glycoside APG1012 is used as a foaming agent; urea is used as a stabilizer to stabilize the foam formed by the fire extinguishing agent and have better film-forming performance;

[0063] (2) Intermediate control:

[0064] The reaction solution obtained in step (1) is adjusted to a pH value of 8.0 by adding caustic soda or potassiu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap