Method for preparing vermiculite carbon nanotube composite material by vertical microwave reactor

A technology of microwave reactors and carbon nanotubes, applied in chemical instruments and methods, carbon compounds, silicon compounds, etc., can solve problems such as low efficiency, high energy consumption, and many pollutants, and achieve rapid heating and low energy loss , the effect of uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

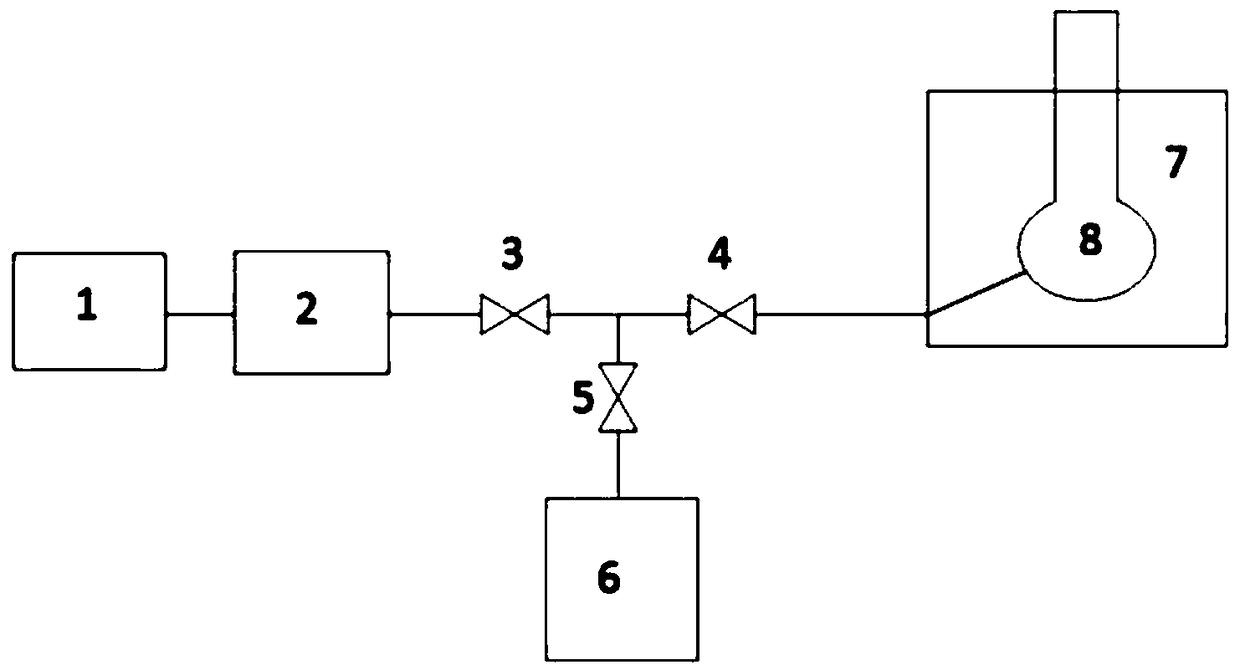

[0033] like figure 1 As shown, the process of preparing the vermiculite carbon nanotube composite material in the vertical microwave reactor specifically includes:

[0034] 1) Add 1g of raw ore vermiculite into a vertical microwave reactor, vacuumize it, and expand it with microwave heating at 800W to obtain expanded vermiculite;

[0035] 2) After step 1) is completed, lower the temperature, pass inert gas tangentially to replace the air in the vertical microwave reactor, and microwave to heat to 600°C;

[0036] 3) Keep the temperature at 600°C and continue microwave heating, heat and vaporize 0.5g of ferrocene, heat and vaporize 25ml of pyridine, and put them into the vertical spherical tube in a spiral manner, one-step catalytic reaction for 10 minutes to obtain the vermiculite carbon nanotube composite material .

[0037] The volume of the raw vermiculite heated by microwave will expand by 15 times, and the length of expanded vermiculite can be increased by about 25 times...

Embodiment 2

[0039] like figure 1As shown, the process of preparing the vermiculite carbon nanotube composite material in the vertical microwave reactor specifically includes:

[0040] 1) Add 1.5g of raw ore vermiculite into a vertical microwave reactor, vacuumize, and expand by microwave heating at 800W to obtain expanded vermiculite;

[0041] 2) After step 1) is completed, lower the temperature, pass inert gas tangentially to replace the air in the vertical microwave reactor, and microwave to heat to 900°C;

[0042] 3) Keep the temperature at 900°C and continue microwave heating. Heat and vaporize 0.75g of cobalt dicene and 30ml of benzene. After mixing, it is spirally passed into the vertical spherical tube, and the one-step catalytic reaction is 120min to obtain the vermiculite carbon nanotube composite. Material.

[0043] The volume of the raw vermiculite heated by microwave will expand by 16 times, and the length of expanded vermiculite can be increased by about 25 times by interca...

Embodiment 3

[0045] like figure 1 As shown, the process of preparing the vermiculite carbon nanotube composite material in the vertical microwave reactor specifically includes:

[0046] 1) Add 3g of raw ore vermiculite into a vertical microwave reactor, vacuumize, and expand by microwave heating at 800W to obtain expanded vermiculite;

[0047] 2) After step 1) is completed, lower the temperature, pass inert gas tangentially to replace the air in the vertical microwave reactor, and microwave to heat to 700°C;

[0048] 3) Keep the temperature at 700°C and continue microwave heating, heat and vaporize 1.5g of ferrocene, heat and vaporize 30ml of trimethylbenzene, mix and spirally pass it into a vertical spherical tube, one-step catalytic reaction for 20min to obtain vermiculite carbon nano Tube composites.

[0049] The volume of the raw vermiculite heated by microwave will expand by 15 times, and the length of expanded vermiculite can be increased by about 25 times by intercalating such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com