Integrated full-automatic direct driving roller car and control method thereof

A roller car, fully automatic technology, applied in the field of roller car, to achieve the effect of simple and convenient control parameters, improve efficiency, simplify operation and maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

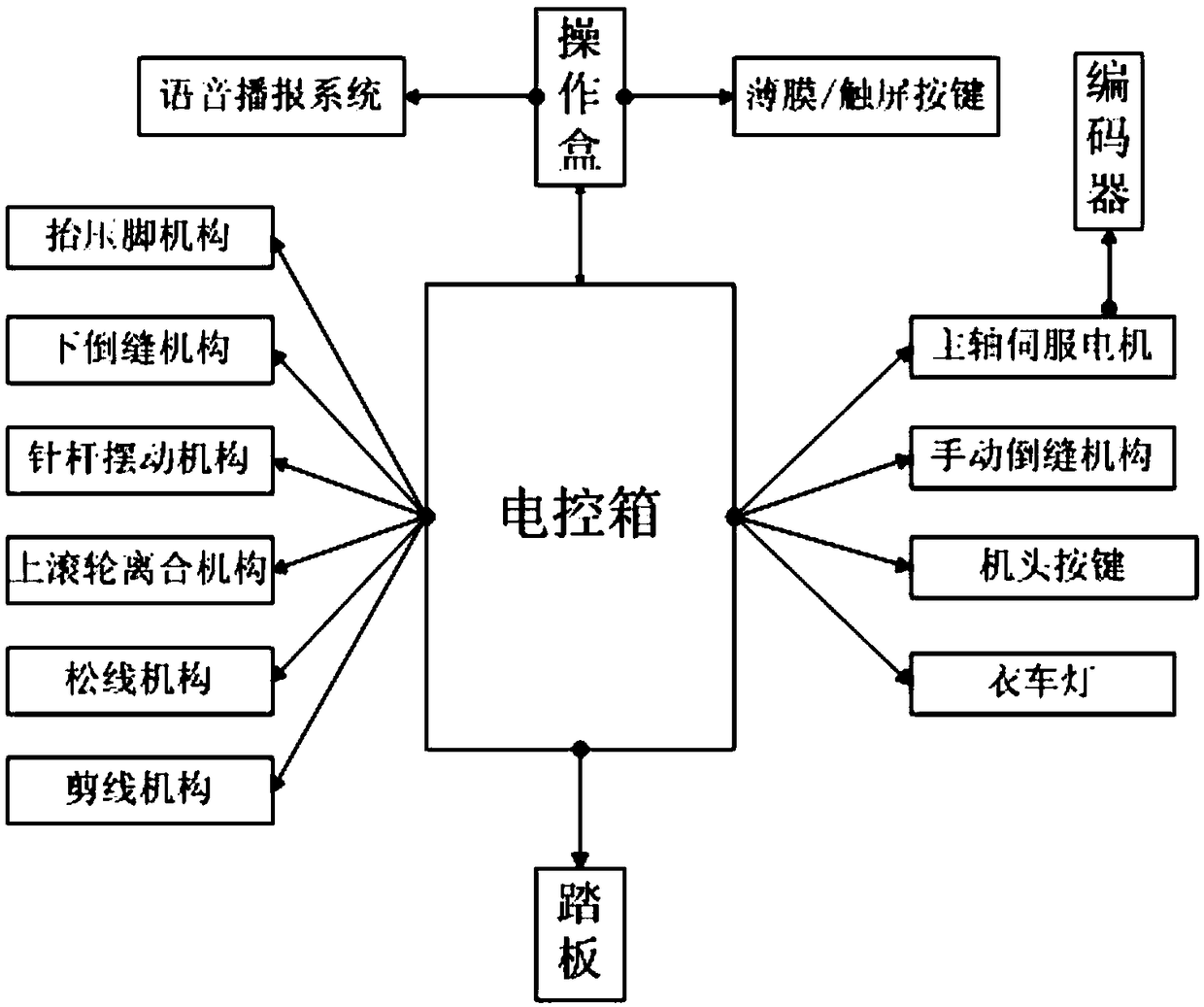

[0030] figure 1 The structure diagram of the integrated fully automatic direct-drive roller car provided by the present invention.

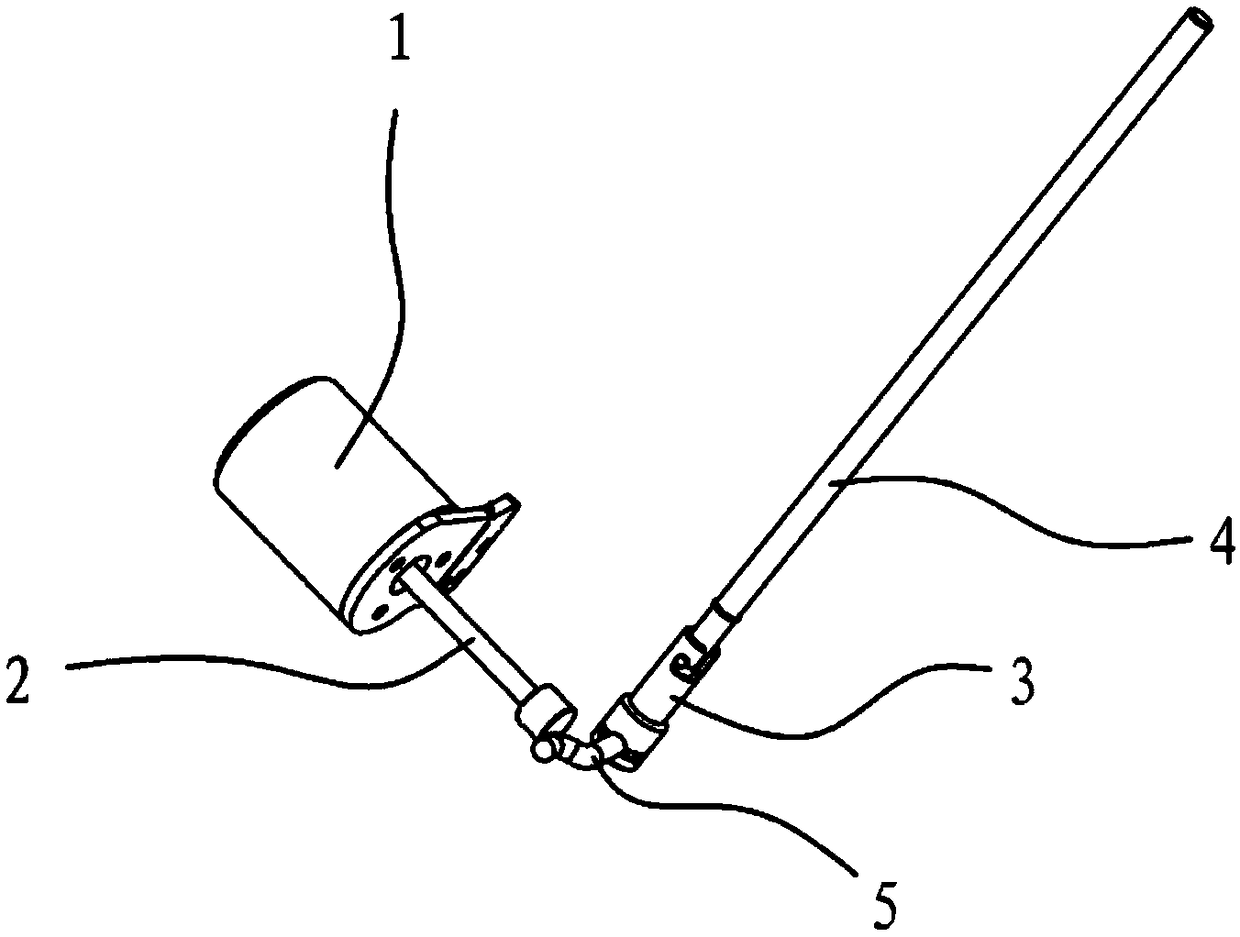

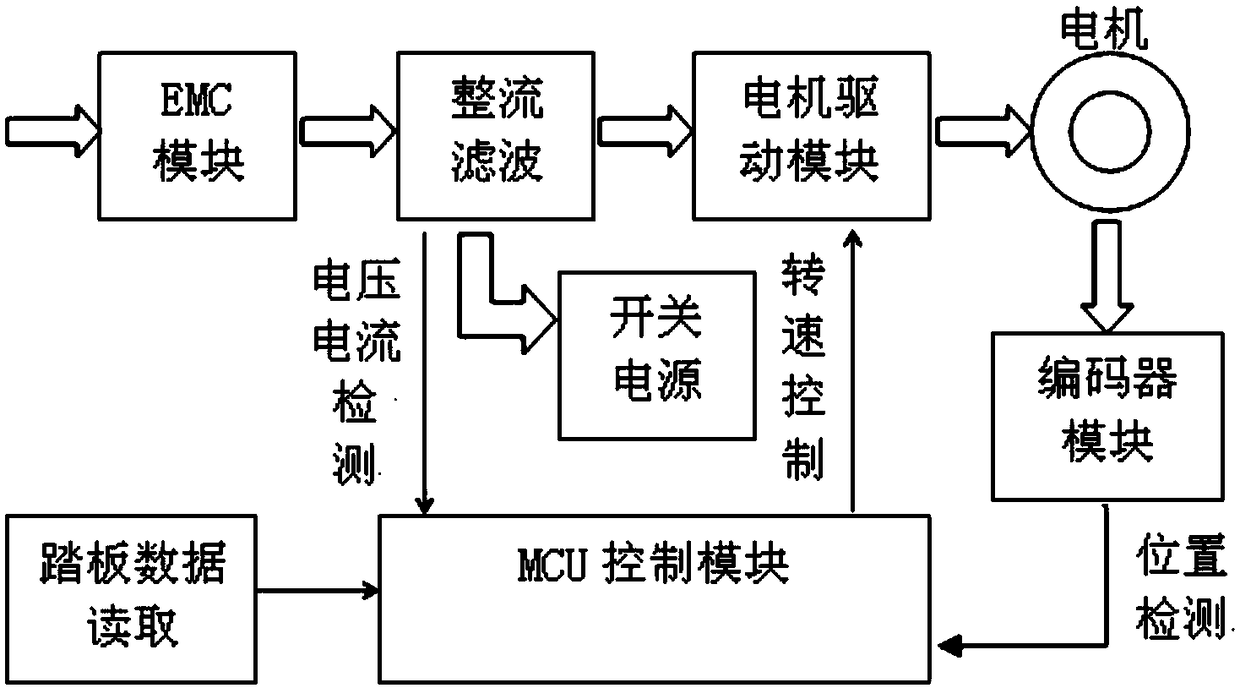

[0031] See figure 1 , the integrated fully automatic direct-drive roller car provided by the present invention includes a roller car body, and the roller car body is provided with a main shaft mechanism, a presser foot lifting mechanism, a needle bar swing mechanism, an upper roller clutch mechanism and a lower reverse sewing mechanism, so that An electric control box is arranged on the side of the roller car body, and an MCU control module and a motor drive module are arranged in the electric control box. Mechanism and lower reverse sewing mechanism; the needle bar swing mechanism, upper roller clutch mechanism and lower reverse sewing mechanism cooperate to realize reverse sewing; the main shaft mechanism is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com