Vibration damping pad for washing machine

A vibration-absorbing pad and washing machine technology, applied in the field of vibration-absorbing pads, can solve the problems of severe shaking, louder noise, and greater amplitude, and achieve the effects of enhancing sound-absorbing and vibration-damping performance, reducing amplitude, and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

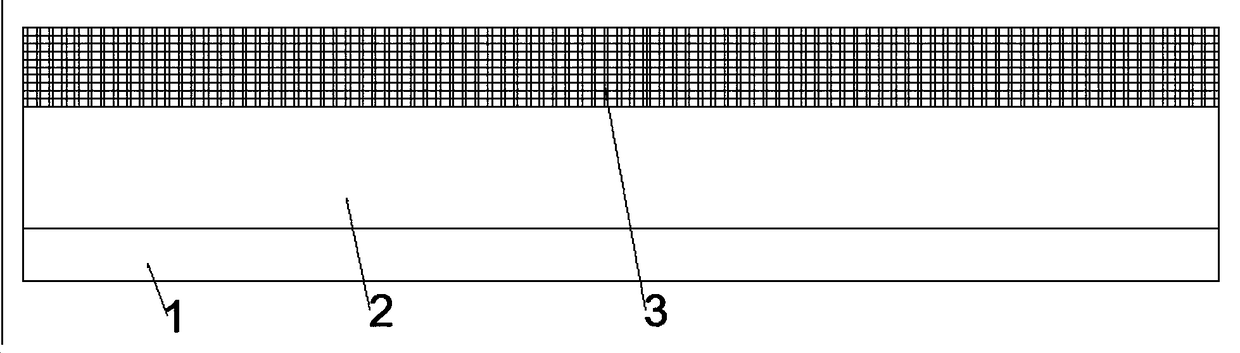

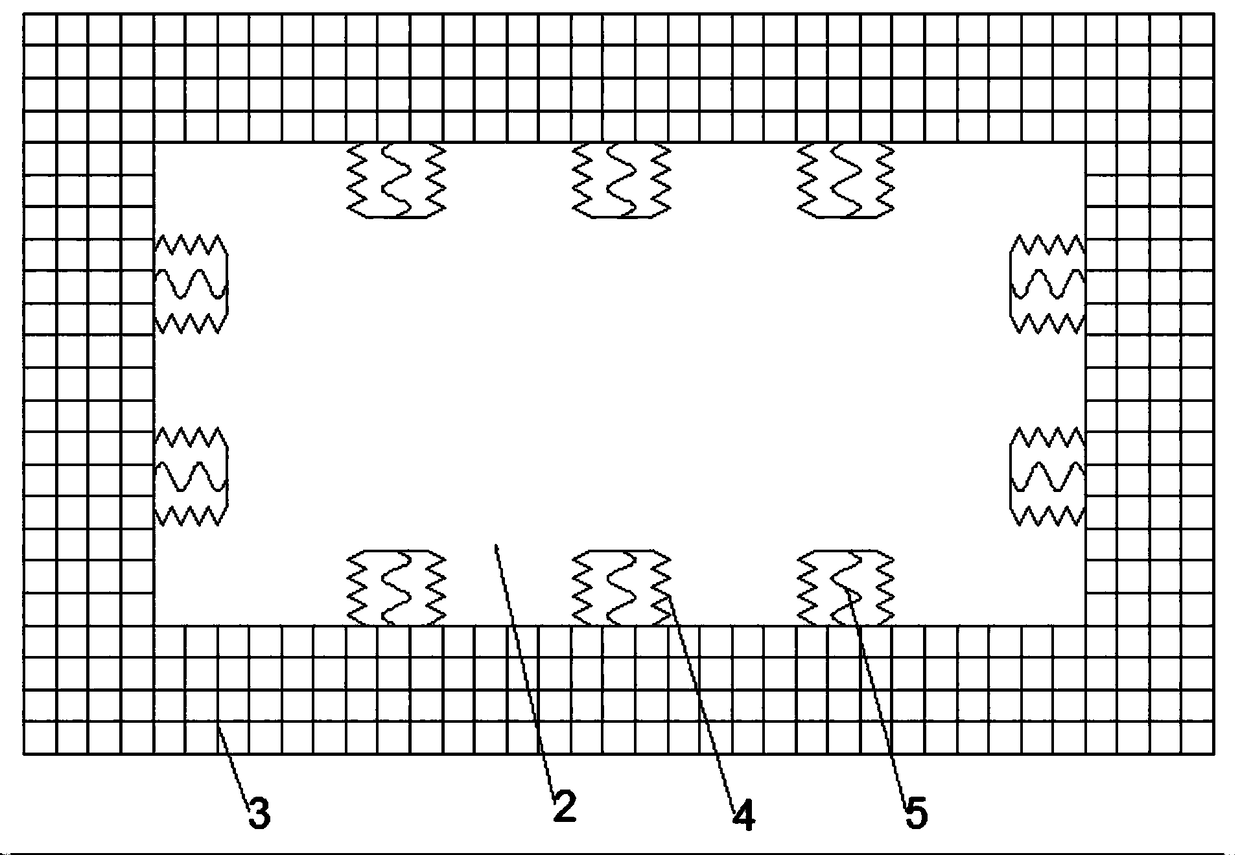

[0022] Such as Figure 1-2 As shown, a vibration damping pad for a washing machine includes a lower metal layer 1, a base layer 2, and an upper metal layer 3, and the lower metal layer 1 and the upper metal layer 3 are respectively arranged on the lower end and the upper end of the base layer 2, and the The upper metal layer 3 is in the shape of a square ring, and the inner wall of the upper metal layer 3 is evenly provided with a telescopic sleeve 4. The diameter of the largest cross-section of the telescopic sleeve 4 is 1 cm, and the length after elongation is 2 cm. The telescopic sleeve 4 There is a spring 5 inside, the outer surface of the lower metal layer 1, base layer 2 and upper metal layer 3 is coated with a protective layer, the lower metal layer 1 is a stainless steel plate, and the upper metal layer 3 is made of ten layers of wire The nets are overlapped, and the pores of the wire mesh are filled with mica flakes and epoxy resin. The mass ratio of the glass flakes ...

Embodiment 2

[0025] A vibration damping pad for a washing machine, comprising a lower metal layer, a base layer, and an upper metal layer, the lower metal layer and the upper metal layer are respectively arranged at the lower end and the upper end of the base layer, the upper metal layer is in the shape of a square ring, and the The inner wall of the above metal layer is evenly provided with a telescopic sleeve, the diameter of the maximum cross-section of the telescopic sleeve is 2 cm, and the length after elongation is 3 cm, a spring is arranged in the telescopic sleeve, and the lower metal layer, the base layer, The outer surface of the upper metal layer is coated with a protective layer, the lower metal layer is a stainless steel plate, the upper metal layer is formed by overlapping fifteen layers of wire mesh, and the pores of the wire mesh are filled with mica scales and rings. Oxygen resin, the mass ratio of described glass flake and epoxy resin is 7:2, and described wire mesh is bar...

Embodiment 3

[0028] A vibration damping pad for a washing machine, comprising a lower metal layer, a base layer, and an upper metal layer, the lower metal layer and the upper metal layer are respectively arranged at the lower end and the upper end of the base layer, the upper metal layer is in the shape of a square ring, and the The inner wall of the above metal layer is evenly provided with a telescopic sleeve, the diameter of the maximum cross-section of the telescopic sleeve is 3cm, and the length after elongation is 4cm, a spring is arranged in the telescopic sleeve, and the lower metal layer, base layer, The outer surface of the upper metal layer is coated with a protective layer, the lower metal layer is a stainless steel plate, and the upper metal layer is formed by overlapping 18 layers of wire mesh, and the pores of the wire mesh are filled with mica scales and rings. Oxygen resin, the mass ratio of described glass flakes and epoxy resin is 7:2, and described wire mesh is copper wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com