Construction process of stock yard

A process and stockyard technology, which is applied in the construction field of closed stockyards in raw material areas, can solve problems such as high cost and low efficiency, and achieve the effects of saving labor costs, significant economic benefits, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

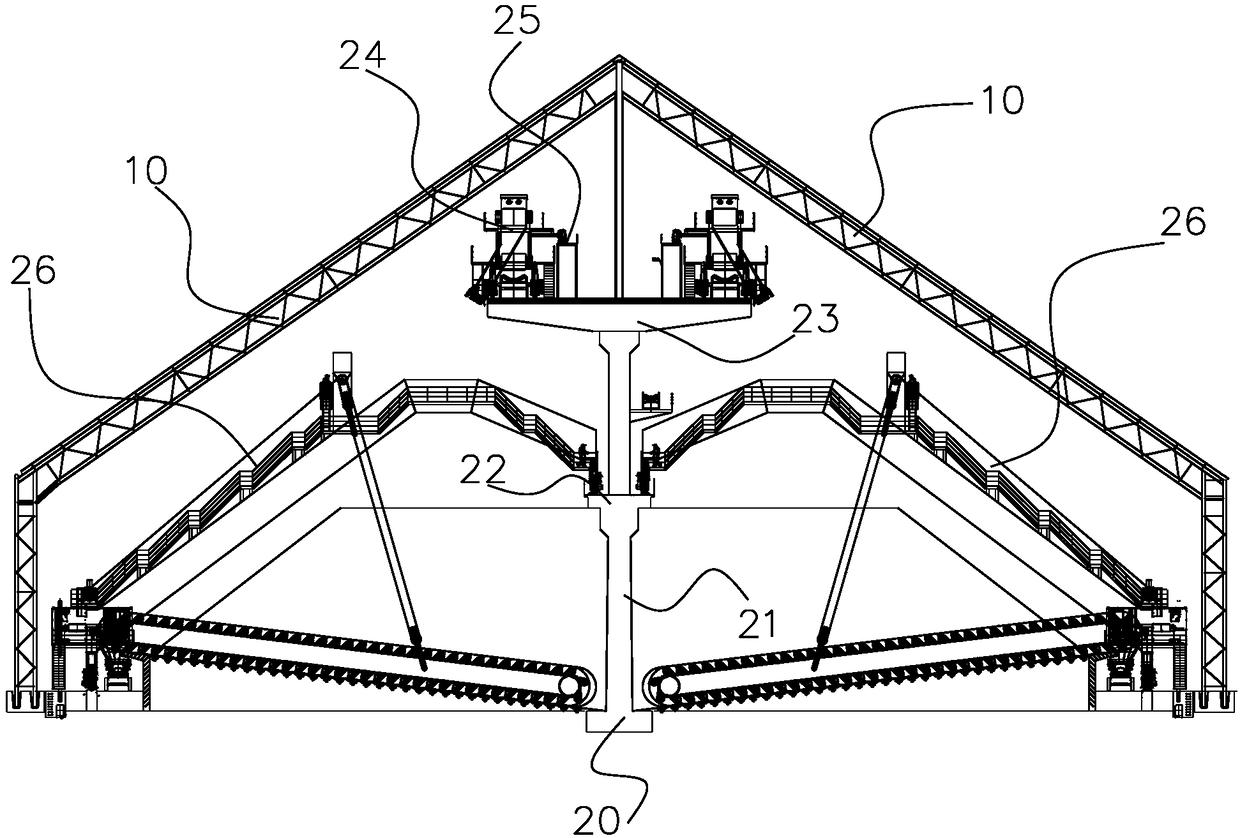

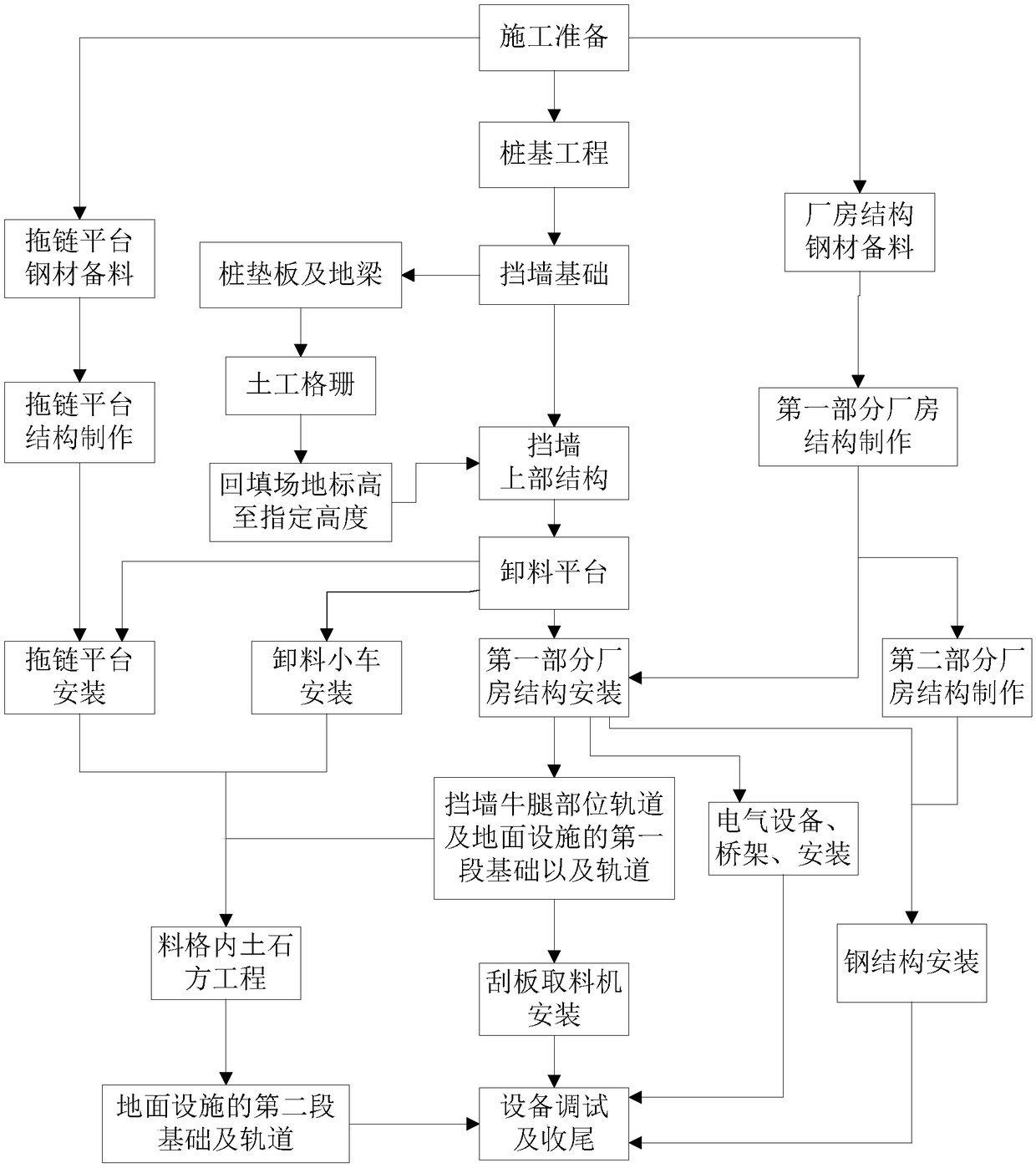

[0022] Such as figure 1 and figure 2 As shown, the present embodiment provides a construction process for closing a stockyard, including the following steps: Step S1: After the pile foundation construction is completed, the retaining wall foundation 20 is constructed, and then the upper structure 21 of the retaining wall is constructed, wherein the After the construction of the retaining wall foundation 20 is completed, the pile backing plate and the ground beam are constructed, and then the site elevation is backfilled to a specified height, and the construction of the upper structure 21 of the retaining wall is continued until the construction of the upper structure 21 of the retaining wall is completed; step S2 : Construction of unloading platform 23, then install the first part of the factory building structure, secondly install the retaining wall corbel position track and the first section foundation and track construction of the ground facilities, then install the scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com