Industrial remote controller

A remote control and industrial technology, applied in the field of automatic control, can solve the problems of troublesome operation, inconvenient operation, and high after-sales cost for users, and achieve the effect of reducing matching costs, improving anti-interference ability, and simple after-sales service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

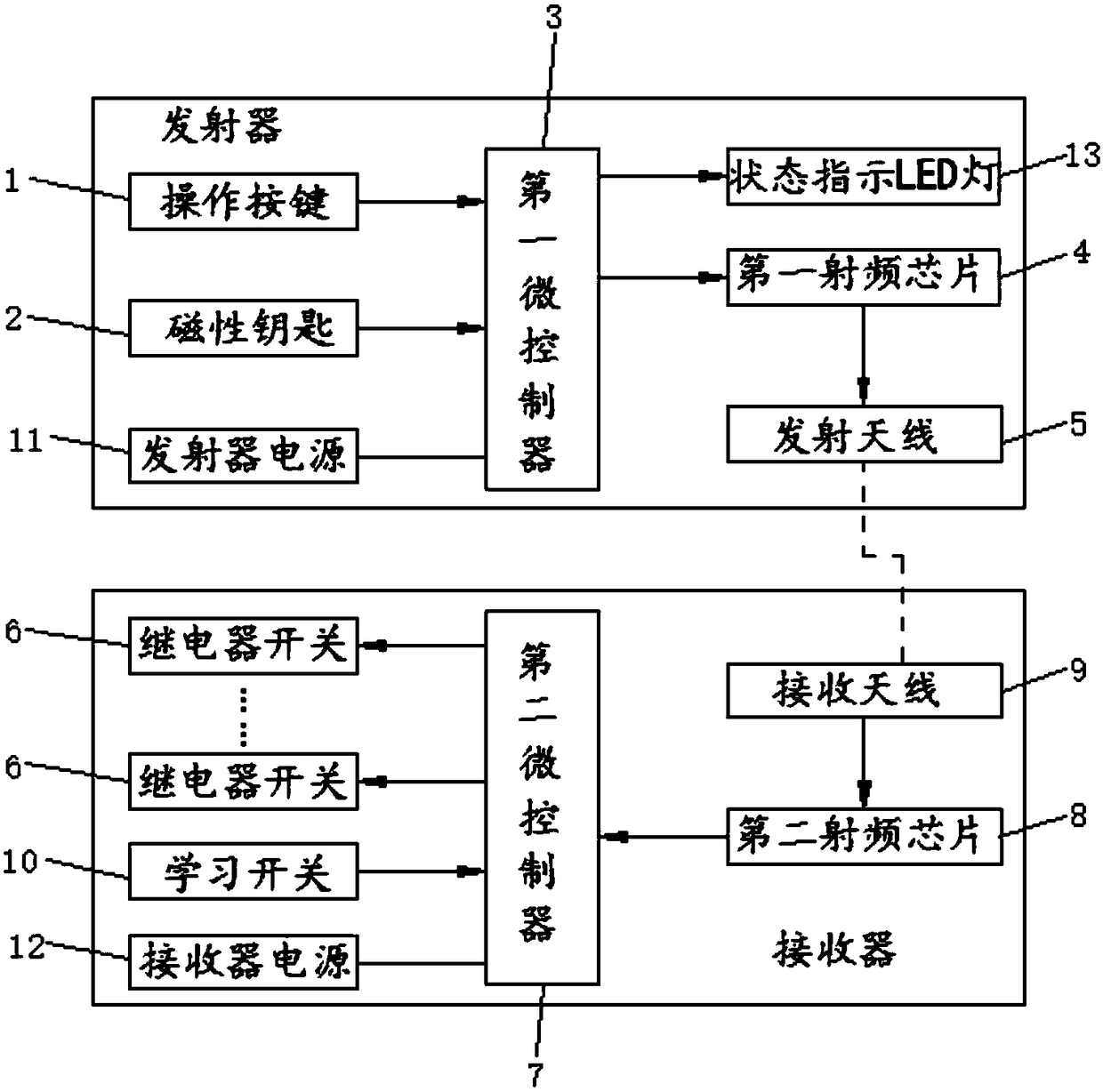

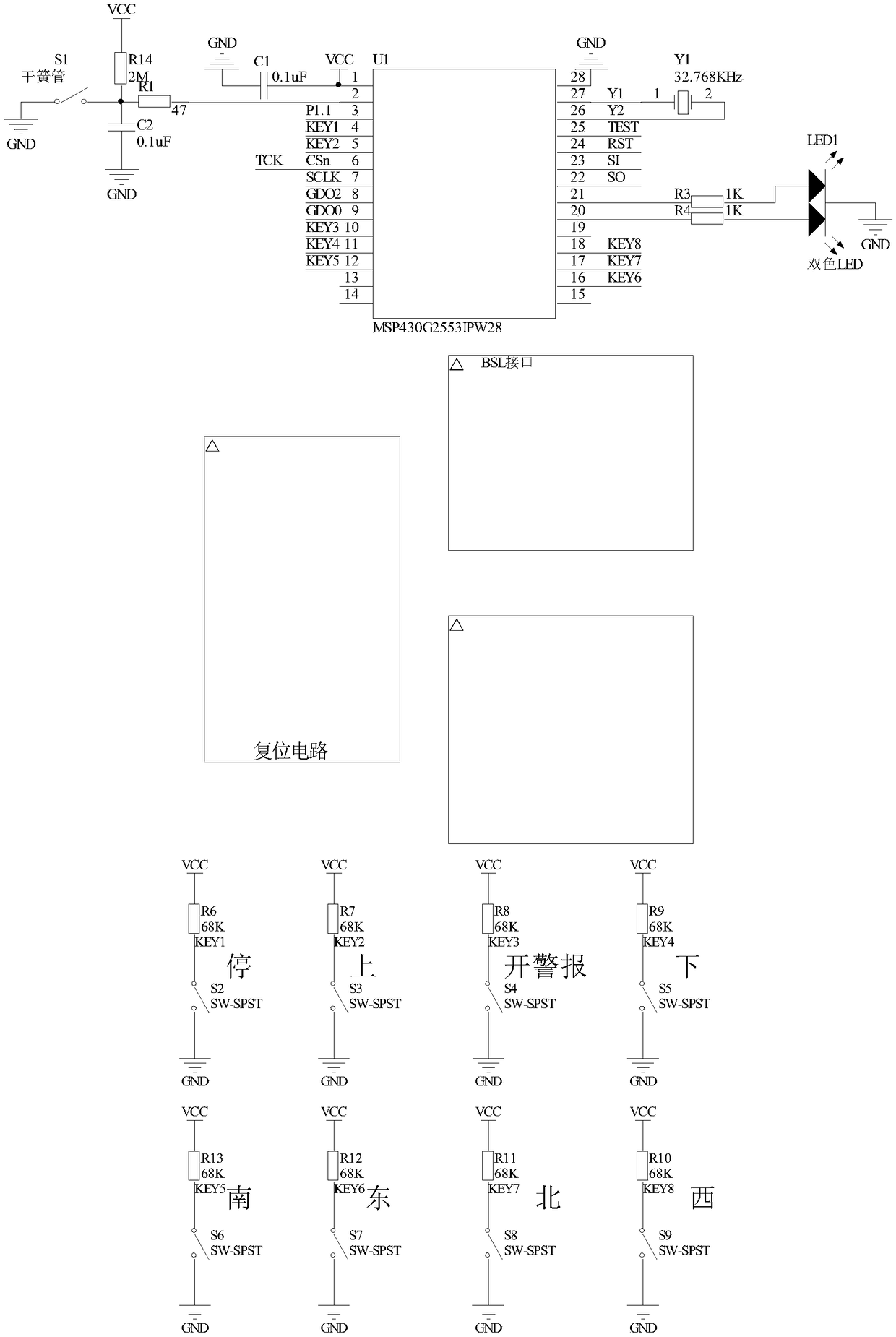

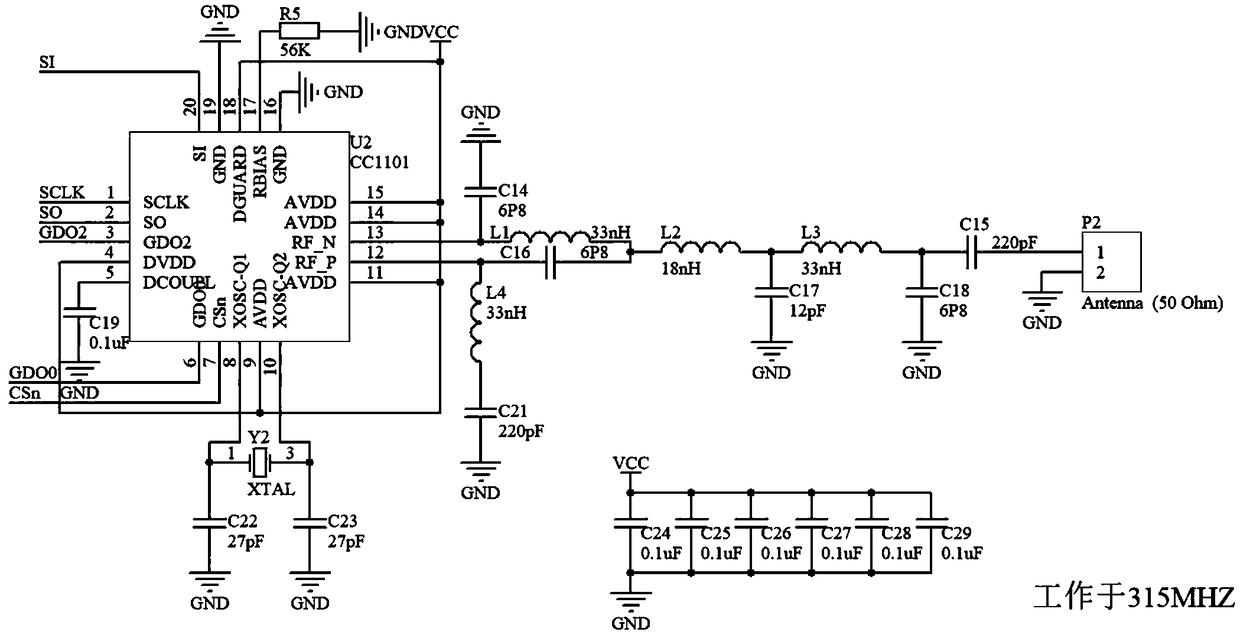

[0039] The invention provides an industrial remote control, specifically as figure 1 As shown, including the transmitter and receiver, both the receiver and the transmitter have a learning function. The transmitter includes an operation button 1, a magnetic key 2, a first microcontroller 3, a first radio frequency chip 4, and a transmitting antenna 5, and the receiver includes a second microcontroller 7, a second radio frequency chip 8, a receiving antenna 9, and a learning switch 10 and multi-way relay switch 6;

[0040] The connection relationship of each part is: the operation button 1 and the magnetic key 2 are all electrically connected to the signal input end of the first microcontroller 3, and the signal receiving end of the first radio frequency chip 4 is electrically connected to the signal output end of the first microcontroller 3. Connect, the signal transmitting end of the first radio frequency chip 4 is electrically connected with the transmitting antenna 5;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com