High-heat-flux vehicle-mounted transformer heat dissipation module and heat dissipation module group

A heat dissipation module and transformer technology, applied in transformer/inductor casing, transformer/inductor cooling, transformer/inductor components, etc., can solve the problems of limited heat dissipation efficiency and insufficient heat dissipation of transformer capacity, and achieve compact structure and effective Protection, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

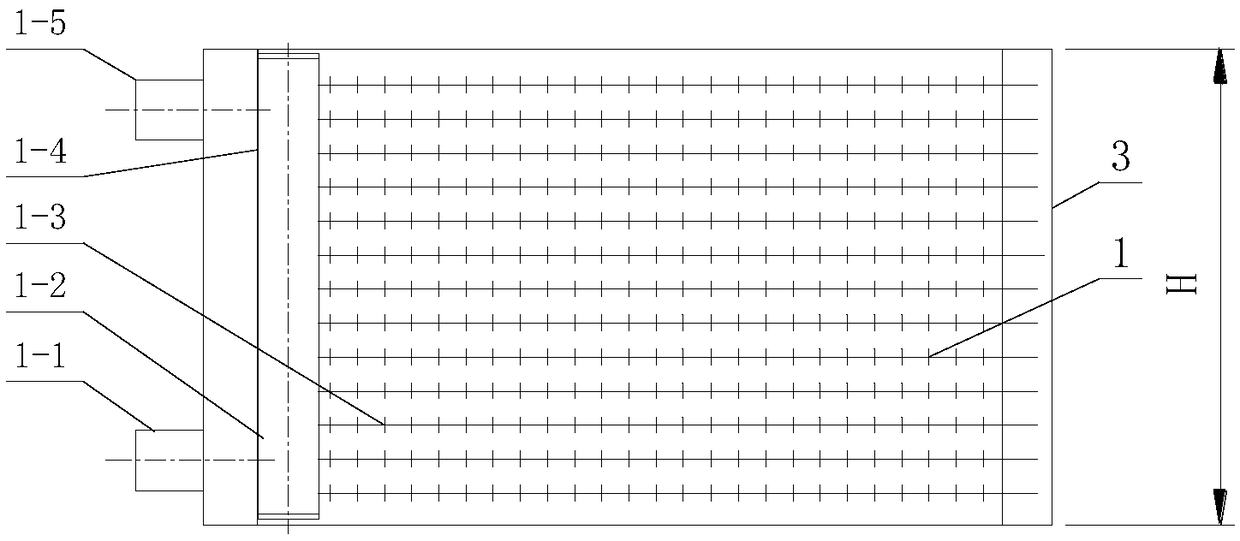

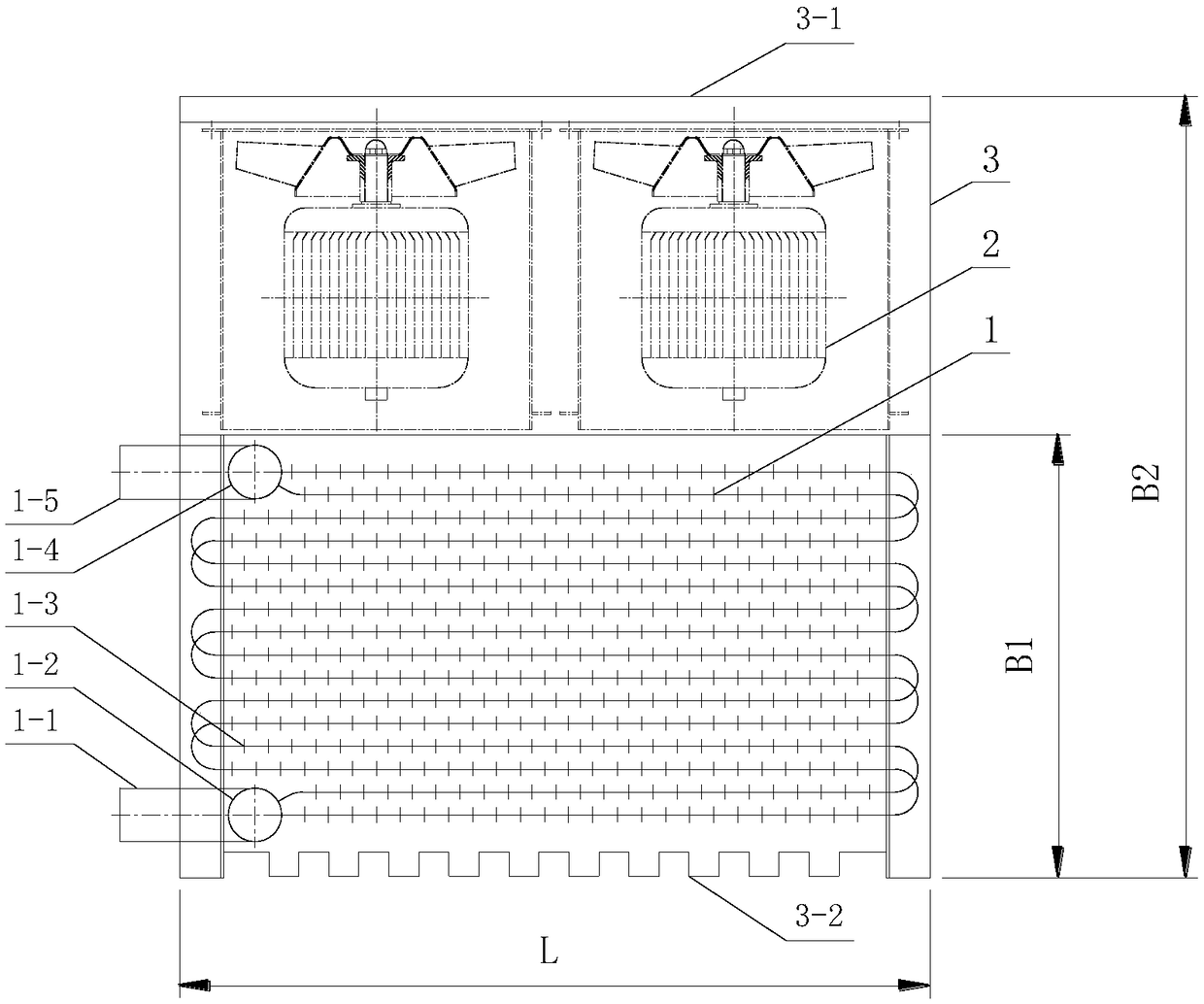

[0038] like figure 1 and figure 2 As shown, a single module of the present invention includes a heat dissipation tube bundle 1 , a high-pressure damping fan 2 and a housing 3 .

[0039] like figure 1 As shown, the heat dissipation tube bundle 1 includes an oil inlet pipe 1-1, an inlet header 1-2, a convective heat exchange tube 1-3, an outlet header 1-4, and an oil outlet pipe 1-5. The oil inlet pipe 1-1 communicates with the lower part of the inlet header 1-2 with both ends closed; the oil outlet pipe 1-4 communicates with the upper part of the outlet header 1-4 with both ends closed. The straight sections of the convective heat exchange tubes 1-3 are connected by equal-diameter 180° elbows, and the two ends are connected with the inlet and outlet headers. Therefore, the combination of multi-standard modules can be flexibly realized.

[0040] like figure 2 As shown, the airflow direction of the high-pressure vibration-reducing fan 2 is perpendicular to the axial directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle α | aaaaa | aaaaa |

| Mesh aperture | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com