Signal-pump beam combiner capable of keeping high beam quality

A high-beam and beam combiner technology, applied in the coupling of optical waveguides, lasers, laser components, etc., can solve the problem of no signal transition fiber, difficult to achieve super large mode field, signal-pump combiner output mode field diameter Small problems, to achieve the effect of maintaining beam quality, reducing insertion loss, and high coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

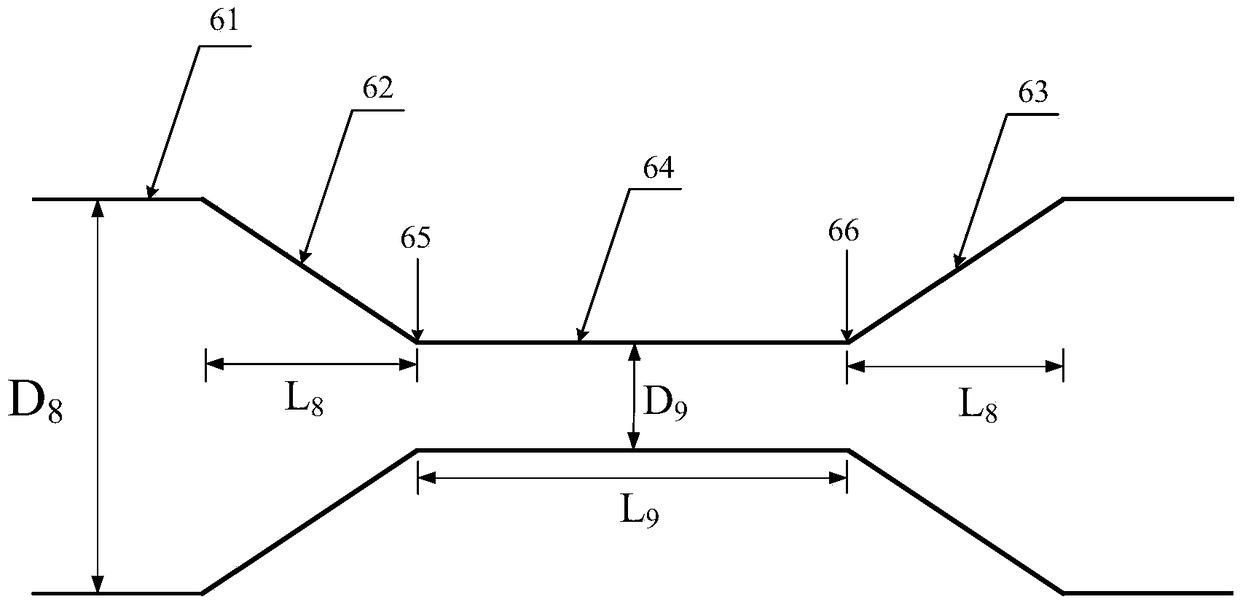

[0024] figure 2 It is a schematic diagram of the taper structure of the components of the present invention. These components of the signal transition fiber 2 of the present invention, the low-refractive index glass tube 4, the fused fiber bundle, and the output optical fiber 5 all pass through the taper. Area, cutting point, this picture is specially drawn for illustration. Among them, 61 represents the initial shape of the part before tapering, and the diameter of the part is D 8 , 62, 63 are the cone areas formed during the tapering process, 62 is the input end cone area, 63 is the output end cone area, L 8 is the length of the taper region, 64 is the waist region formed by the taper process, L 9 is the waist length, D 9 is the diameter of the tapered waist area, 65 is the input end cutting point (i.e. the boundary position between the input end cone area and the waist area), and 66 is the output end cutting point (i.e. the boundary position between the waist area and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com