Fructus hippophae essential oil microcapsule and preparation method thereof

A sea buckthorn essential oil and sea buckthorn technology are applied in the field of sea buckthorn essential oil microcapsules and preparation thereof, and can solve the problems of difficulty in preservation and low stability of sea buckthorn essential oil, and achieve the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present embodiment provides a preparation method of sea buckthorn essential oil microcapsules, which comprises:

[0022] Step S1: Mix the essential oil of sea buckthorn, the emulsifier solution and the coating liquid in which the coating material is dissolved, and emulsify and stir to obtain an emulsion.

[0023] Step S2: spray drying the emulsion obtained in step S1.

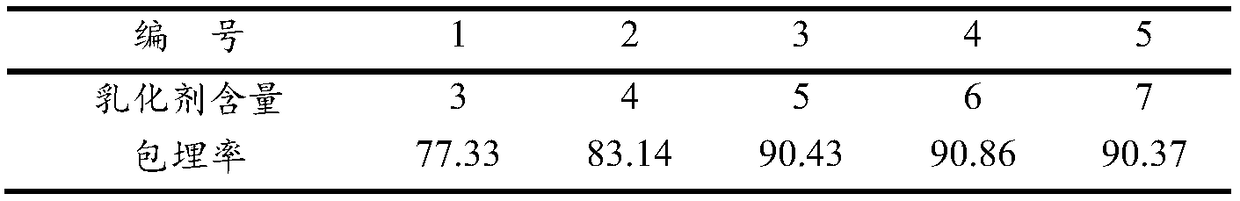

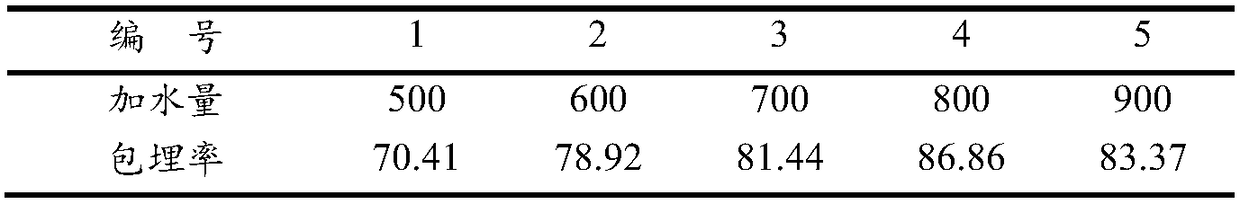

[0024] The following takes Tween 80 as an emulsifier, and takes hydroxypropyl-β-cyclodextrin as a coating material, and the embedding rate of the essential oil of sea buckthorn is an evaluation parameter, and each parameter in the preparation process is set and optimized:

[0025] 1. Recipe dosage:

[0026] 1.1 Dosage of hydroxypropyl-β-cyclodextrin:

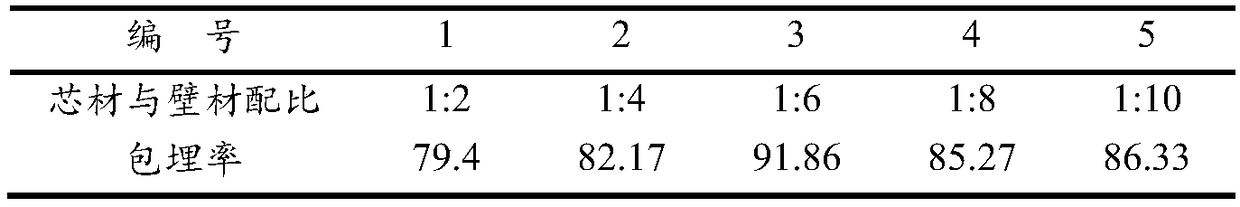

[0027] The inventors selected the mass ratios of the microcapsule core material (sea buckthorn essential oil) and the coating wall material (hydroxypropyl-β-cyclodextrin) to be 1:2, 1:4, 1:6, 1:8, 1:2, respectively. 10 scale. Adopt the following pa...

Embodiment 1

[0076] The present embodiment provides a microcapsule of sea buckthorn essential oil, and its preparation method includes:

[0077] a. Weigh 48 g of hydroxypropyl-β-cyclodextrin, dissolve it with hot water at 70°C, and stir until it is evenly dispersed to obtain a coating solution;

[0078] b. dissolve and dissolve the emulsifier Tween-80 (5g) with 800mL of hot water to obtain an emulsifier solution;

[0079] c. Add 8g of sea buckthorn essential oil and emulsifier solution to the coating solution, and continue to stir rapidly until mixed. The obtained emulsion was poured into a high shear disperser and fully emulsified at 6000r / min for 50min, while maintaining the temperature at 70°C, and finally a white emulsion was obtained.

[0080] d. Drying by spray drying method, the air inlet temperature is 100°C, and the air outlet temperature is 190°C to obtain uniformly dispersed white powdery seabuckthorn oil microcapsules with a particle size of 400 μm.

[0081] The encapsulation...

Embodiment 2

[0083] The present embodiment provides a microcapsule of sea buckthorn essential oil, and its preparation method includes:

[0084] a. Weigh 80 g of hydroxypropyl-β-cyclodextrin, dissolve it with hot water at 75°C, and stir until the dispersion is uniform to obtain a coating solution;

[0085] b. dissolve and dissolve the emulsifier Tween-80 (5g) with 900mL of hot water to obtain an emulsifier solution;

[0086] c. Add 8g of sea buckthorn essential oil and emulsifier solution to the coating solution, and continue to stir rapidly until mixed. The obtained emulsion was poured into a high-shear disperser and fully emulsified for 60 min at a rotation speed of 5000 r / min, while maintaining the temperature at 75 °C, and finally a white emulsion was obtained.

[0087] d. Drying by spray drying method, the air inlet temperature is 110°C, and the air outlet temperature is 200°C to obtain uniformly dispersed white powdery seabuckthorn oil microcapsules with a particle size of 300 μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com