Flushing device for general surgery department

A flushing device and general surgery technology, which is applied in the direction of enema/irrigator, medical science, infusion set, etc., can solve the problems of slow cleaning of wounds and great pain of patients, and achieve simple installation, convenient cleaning, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

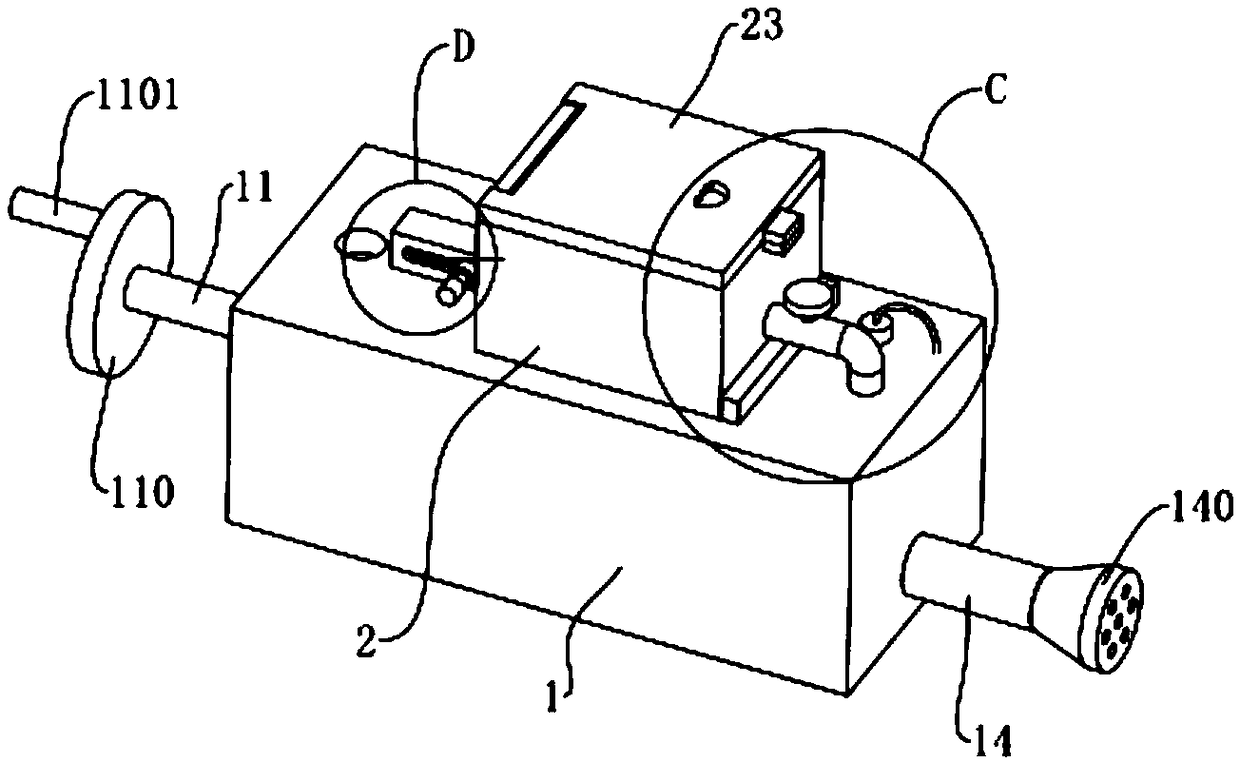

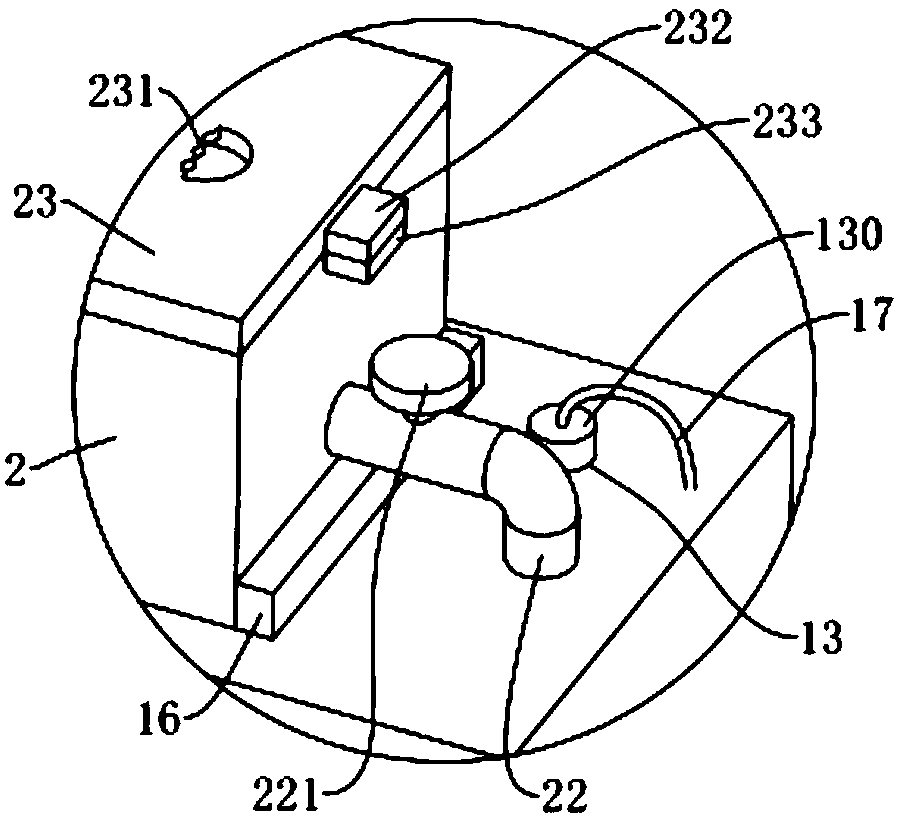

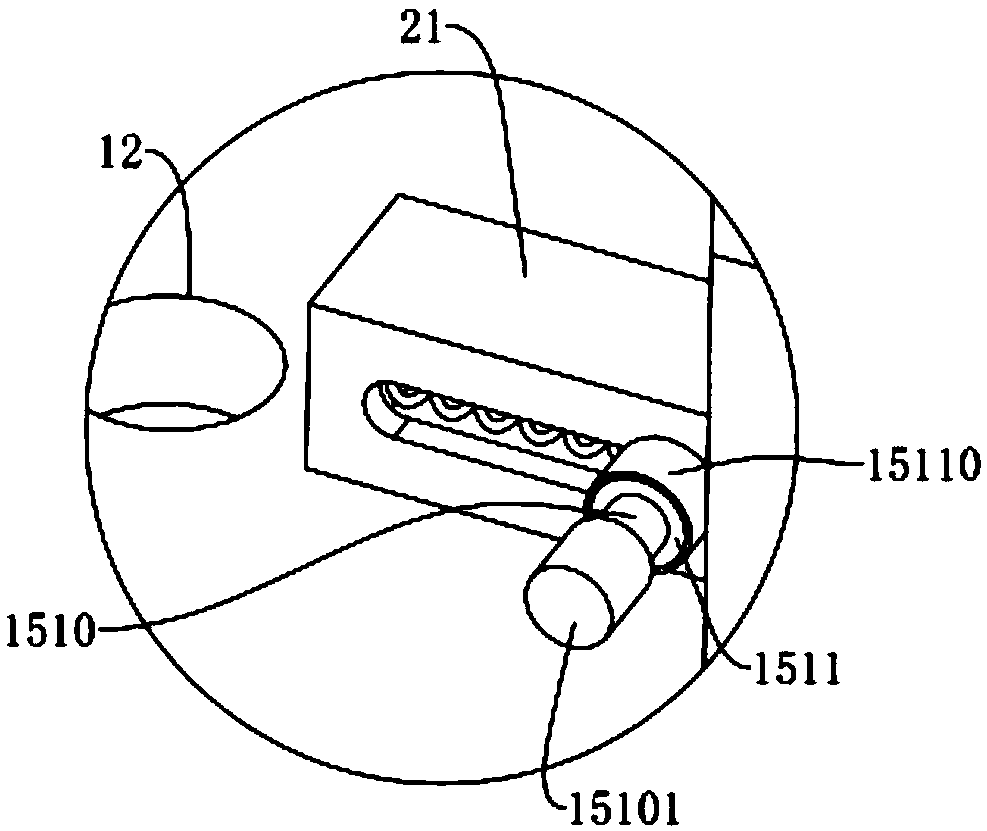

[0041] Such as Figure 1 to Figure 6As shown, a flushing device for general surgery includes a closed first box body 1, wherein a push plate 10 is slidably connected inside the first box body 1, in order to ensure that the push plate 10 and the first box body 1 are empty There is no air leakage between the cavities, and there is good sealing performance. A layer of rubber pad 101 is fixed on the peripheral wall of the push plate 10; in order to drive the push plate 10 to push, a screw 11 is threaded on the first box body 1, wherein the screw 11 One end of the screw is connected to the inside of the push plate 10, and when the screw 11 rotates, the push plate 10 will be driven to slide in the first box body 1; in order to maintain the stability of the air pressure in the first box body 1, a There are a first air pressure balance hole 12 and a second air pressure balance hole 13. A plug 130 is plugged into the second air pressure balance hole 13 of the first box body 1. The firs...

Embodiment 2

[0044] The difference from Example 1 is that the outer surface of the first box body 1 and the second box body 2 is coated with a layer of antifouling coating, because the outer surface of the first box body 1 and the second box body 2 is in the first When the box body 1 and the second box body 2 are used, more dust will be accumulated. In order to prevent the dust from sticking to the surface of the first box body 1 and the second box body 2, which will affect the treatment effect on the patient's wound, and make the first box body The body 1 and the second box body 2 are easier to clean, and the outer surfaces of the first box body 1 and the second box body 2 are coated with an antifouling coating, so a preparation method for the antifouling coating is provided, wherein It has the advantages of short preparation process and simple preparation, wherein the preparation method of the antifouling coating on the outer surface of the first box body 1 and the second box body 2 is as...

Embodiment 3

[0052] The difference from Example 1 lies in the preparation of the antifouling coating on the outer surfaces of the first box body 1 and the second box body 2, wherein the preparation method of the antifouling coating is as follows:

[0053] Take the following components by weight for subsequent use: 31 parts of epoxy resin, 27 parts of polypropylene, 16 parts of polyvinyl chloride, 65 parts of acetone, 5 parts of ethyl acetate, 8 parts of polymethacrylate, methacrylic acid hydroxyl 5 parts of alkyl esters, 6 parts of ethyl methacrylate, 6 parts of disodium edetate, 9 parts of vinylene carbonate;

[0054] S1. Prepare the first prefabricated solution: add epoxy resin, polypropylene, and polyvinyl chloride to acetone, heat the overall temperature to 58° C., and heat-preserve for 28 minutes to fully dissolve the raw materials to obtain the first prefabricated solution;

[0055] S2. Preparation of the second prefabricated solution: mix and stir ethyl acetate, polymethacrylate, hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com