Particulate matter bed layer support structure and high flux axial reactor

A technology of supporting structure and particulate matter, which is applied in the field of high-flux axial reactors, can solve the problems of complex process design and equipment manufacturing of radial reactor structures, limited popularization and application, and bed thickness, etc., so as to reduce the occurrence of side reactions. chance, increased total surface area, increased processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

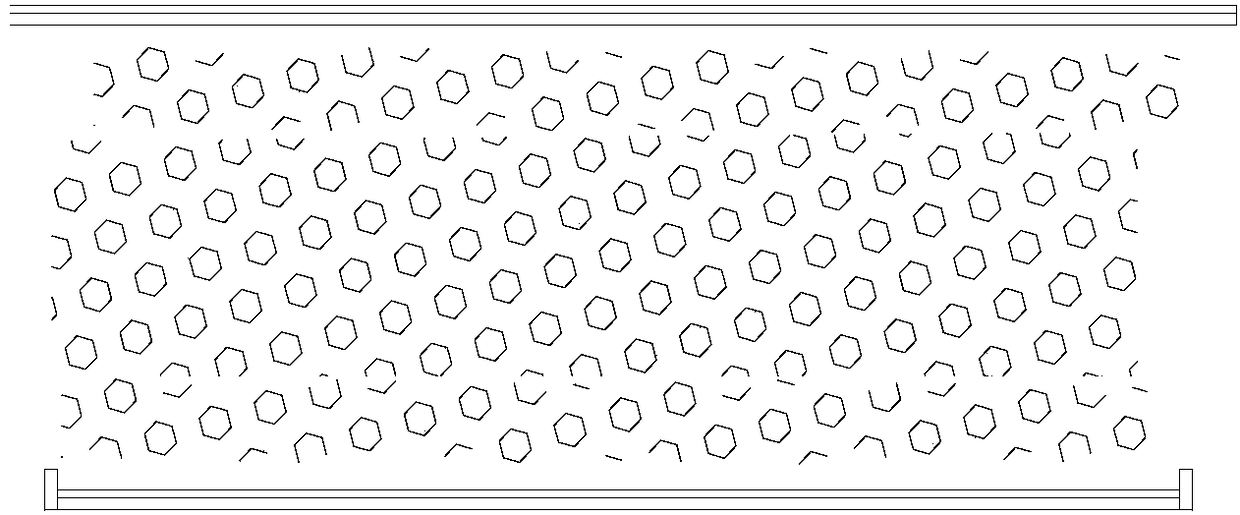

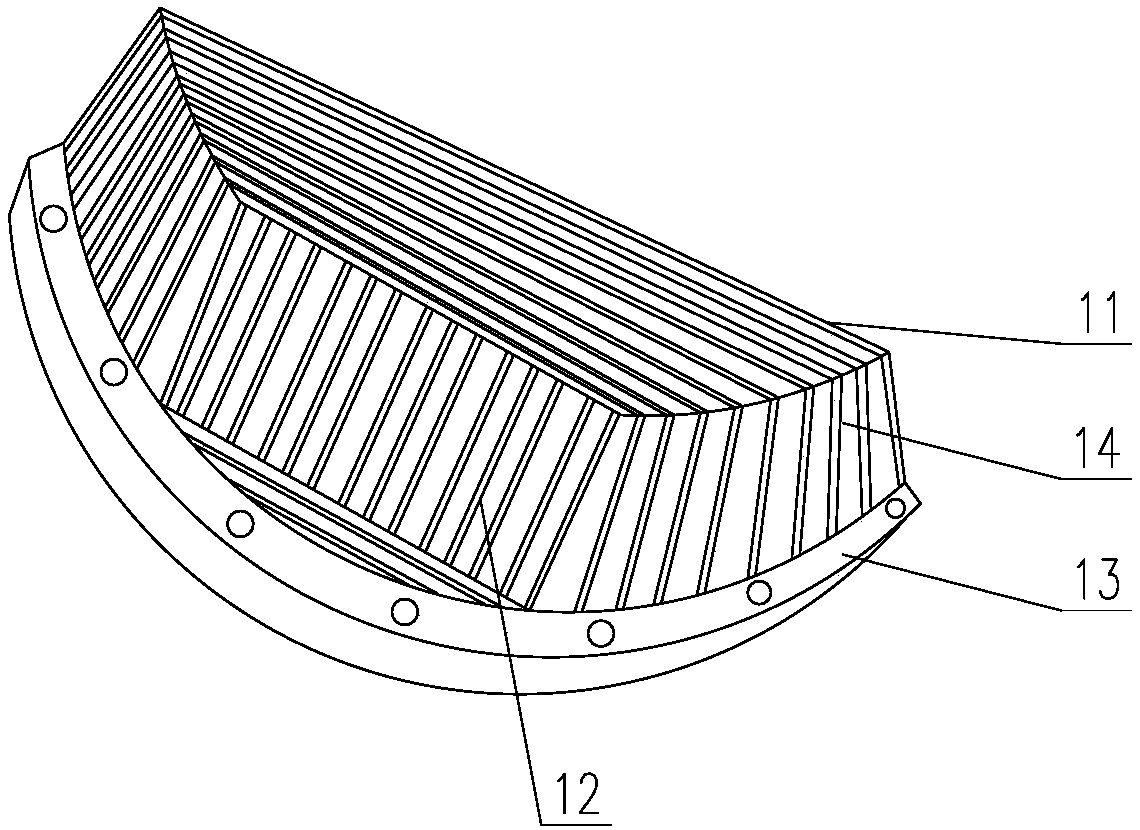

[0039] According to a preferred embodiment of the present invention, the support grid 1 includes a strip-shaped horizontal grid 11, a strip-shaped vertical grid 12, an edge grid 14, and an annular frame 13 that are spliced with each other. The grid 14 is arc-shaped, so that the convex part of the support grid 1 forms a four-sided enclosure structure, and its edge and the bottom surface of the concave part of the support grid 1 are on the same plane, which is convenient for connecting the ring frame 13. This structure can be formed by image 3 It can be clearly seen that the compression grid 2 is formed by splicing a strip-shaped horizontal grid 11 and a strip-shaped vertical grid 12 .

[0040] The protrusions and recesses of the support grid 1 and the compression grid 2 obtained by the above splicing method are respectively composed of parallel strip cuboids, such as Figure 7 shown.

[0041] According to another preferred embodiment of the present invention, the supporting...

Embodiment 1

[0052] This example is used to illustrate the support structure of the particulate matter bed of the present invention.

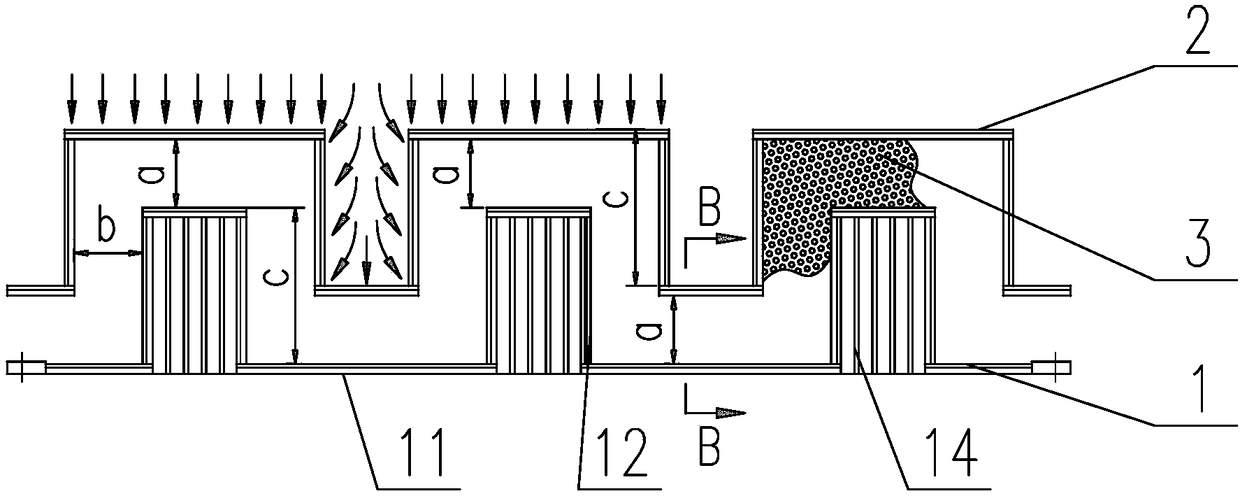

[0053] Such as Figure 2-3 As shown, the support structure of the particulate matter bed layer includes a support grid 1 and a compression grid 2 arranged in the vertical direction, the support grid 1 is located below the compression grid 2, and the support grid 1 and the compression grid 2 have a matching concave-convex structure, so that there is an axial distance a and a lateral distance b between the support grid 1 and the compression grid 2, which is used for setting the particle bed 3.

[0054] The axial spacing a and the lateral spacing b between the support grid 1 and the compression grid 2 are equal, and the axial spacing a and the lateral spacing b between the support grid 1 and the compression grid 2 are also equal, The height c of the vertical grids 12 constituting the supporting grid 1 and the pressing grid 2 are equal.

[0055] The supportin...

Embodiment 2

[0060] This example is used to illustrate the support structure of the particulate matter bed of the present invention.

[0061] The supporting structure of the particle bed layer includes a support grid 1 and a compression grid 2 arranged in the vertical direction, the support grid 1 is located below the compression grid 2, and the support grid 1 and the compression grid The grid 2 has a matching concave-convex structure, so that there is an axial spacing a and a lateral spacing b between the supporting grid 1 and the pressing grid 2, and is used for setting the particle bed 3.

[0062] The axial spacing a and the lateral spacing b between the support grid 1 and the compression grid 2 are equal, and the axial spacing a and the lateral spacing b between the support grid 1 and the compression grid 2 are also equal, The height c of the vertical grids 12 constituting the supporting grid 1 and the pressing grid 2 are equal.

[0063] The support grid 1 and the compression grid 2 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com