High-efficiency standardized iron picture manufacturing process

A production process and iron painting technology, which is applied in the field of efficient and standardized iron painting production technology, can solve problems such as time-consuming and labor-intensive, and achieve the effects of improving production efficiency, shortening the production cycle, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

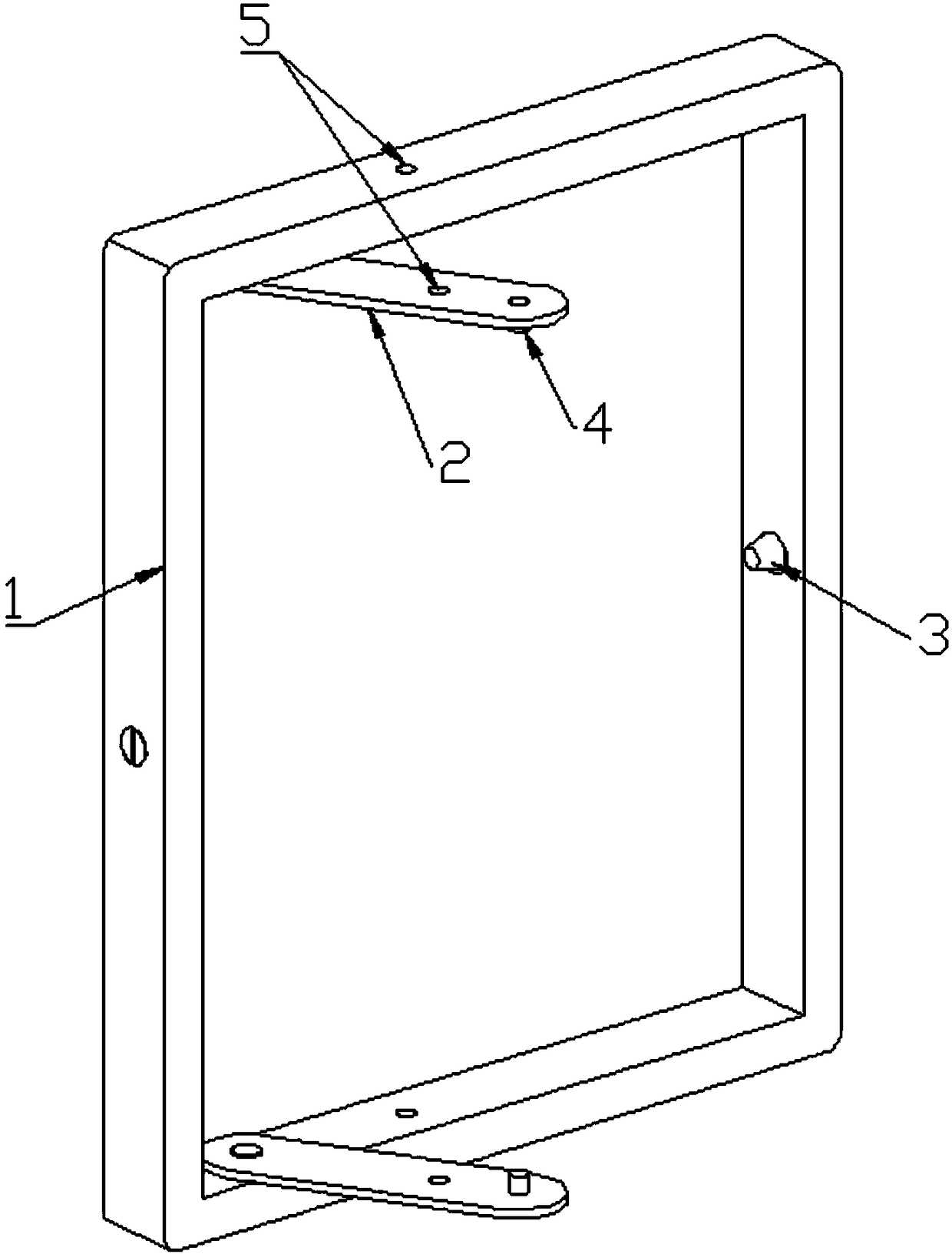

Image

Examples

Embodiment 1

[0026] An efficient and standardized iron painting production process, comprising the following process steps:

[0027] (1) Casting: Divide the main body of the iron painting into multiple modules first, use metal mold casting or sand casting method, cast the above multiple modules into shape, and send them to the conveyor belt corresponding to each module respectively, and enter each module. processing station of each module;

[0028] (2) Processing: The staff at the processing station processes the molded modules into a specified shape by means of stacking, chiseling, and forging, and repairs casting defects on some modules;

[0029] (3) Surface treatment: the processed module is sent to the pickling station, and after four procedures of water washing, pickling, water washing and drying, the surface of the module obtains a dense oxide film, and the surface treatment is completed;

[0030] (4) Assembly: Assemble each module according to the design drawings. After the assembl...

Embodiment 2

[0033] An efficient and standardized iron painting production process, comprising the following process steps:

[0034] (1) Casting: Divide the main body of the iron painting into multiple modules first, use metal mold casting or sand casting method, cast the above multiple modules into shape, and send them to the conveyor belt corresponding to each module respectively, and enter each module. processing station of each module;

[0035] (2) Processing: The staff at the processing station processes the molded modules into a specified shape by means of stacking, chiseling, and forging, and repairs casting defects on some modules;

[0036] (3) Surface treatment: the processed module is sent to the pickling station, and after four procedures of water washing, pickling, water washing and drying, the surface of the module obtains a dense oxide film, and the surface treatment is completed;

[0037] (4) Assembly: Assemble each module according to the design drawings. After the assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com