Novel double-vertical-pipe water discharging system

A drainage system and double standpipe technology, which is applied in water supply installations, indoor sanitation pipe installations, buildings, etc., can solve the problems of occupying space and achieve the effects of saving space, compact structure, and increasing drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

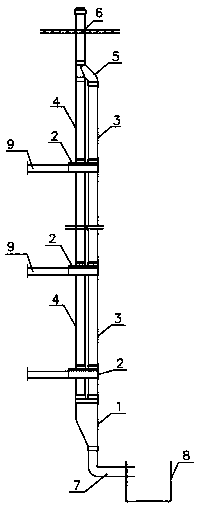

[0042] Such as figure 1 As shown, a novel double riser drainage system includes a drainage riser 4 and an aeration riser 3 arranged side by side, and the tops of the top drainage riser 4 and the aeration riser 3 are connected to the roof extension pipe 6 through a top junction 5 The bottom of the bottom drainage riser 4 and the ventilation riser 3 are connected to the drain pipe 7 through the bottom junction 1, the drain pipe 7 is connected to the inspection well 8, and the drainage lateral branch pipe 9 is connected to the water-gas separation module 2.

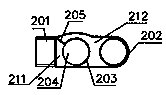

[0043] Such as figure 2 and image 3 As shown, the water-gas separation module 2 includes a closed cavity, the top of the closed cavity is provided with the upper connecting pipe 203 of the drainage standpipe and the upper connecting pipe 202 of the ventilation standpipe, and the bottom of the closed cavity is provided with the lower connecting pipe 206 of the drainage standpipe and the ventilation standpipe. The lower co...

Embodiment 2

[0050] A new double-standpipe drainage system. The difference between this embodiment and Embodiment 1 is that the water-air separation module 2 is patented as "a side vertical reclaimed water storage, treatment, reuse and discharge for toilets." System (Application No.: 201810149057.6)” for the core module 10 (the core module 10 in the above-mentioned patent application), the drainage lateral branch pipe 9 is directly connected to the drainage socket on the core module 10.

Embodiment 3

[0052] Such as Figure 6 As shown, a new type of double-standpipe drainage system, the difference between this embodiment and the first embodiment is that the ventilation riser socket 13 and the drainage riser socket 14 of the bottom junction 1 protrude from the top surface of the housing, and the partition 17 top is located at the top of housing 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com