Connecting member of prefabricated sandwiched heat-insulating wall, heat-insulating wall and construction method thereof

A technology for thermal insulation walls and connectors, applied in thermal insulation, walls, building components, etc., can solve problems such as poor anchoring performance and difficult processing, and achieve low cost, low manufacturing cost, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

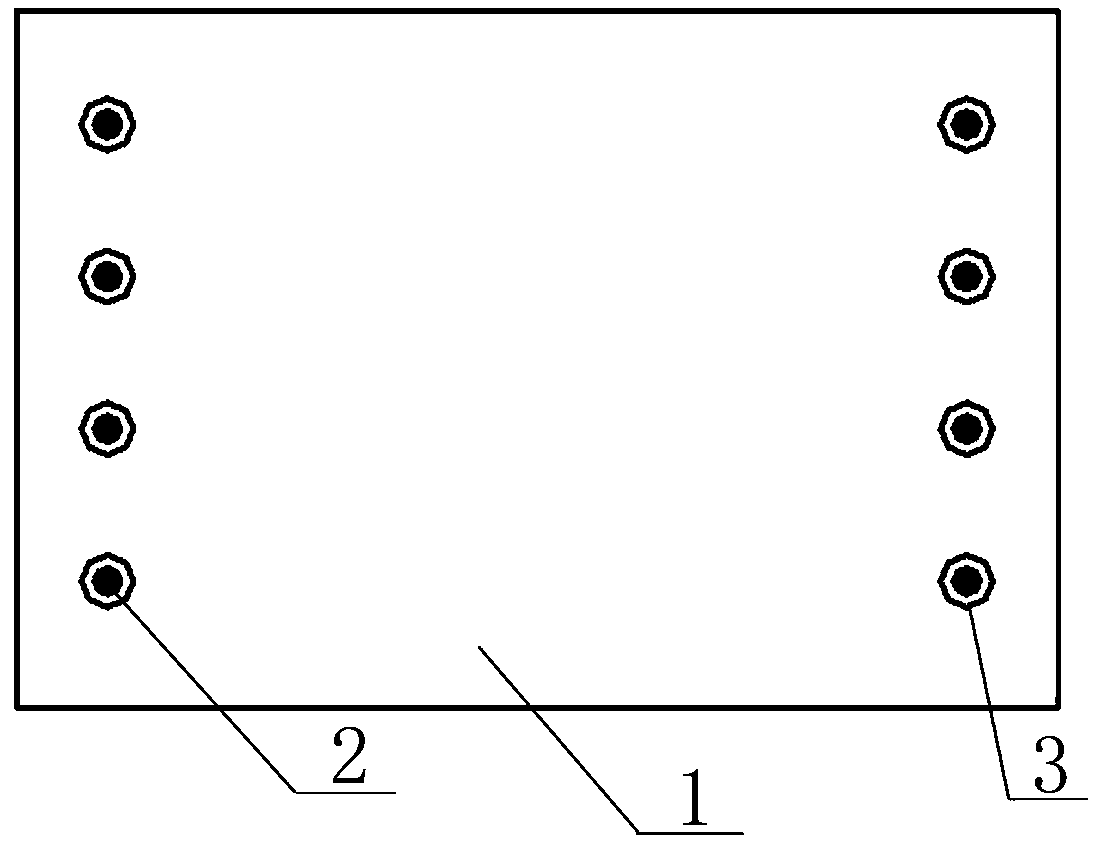

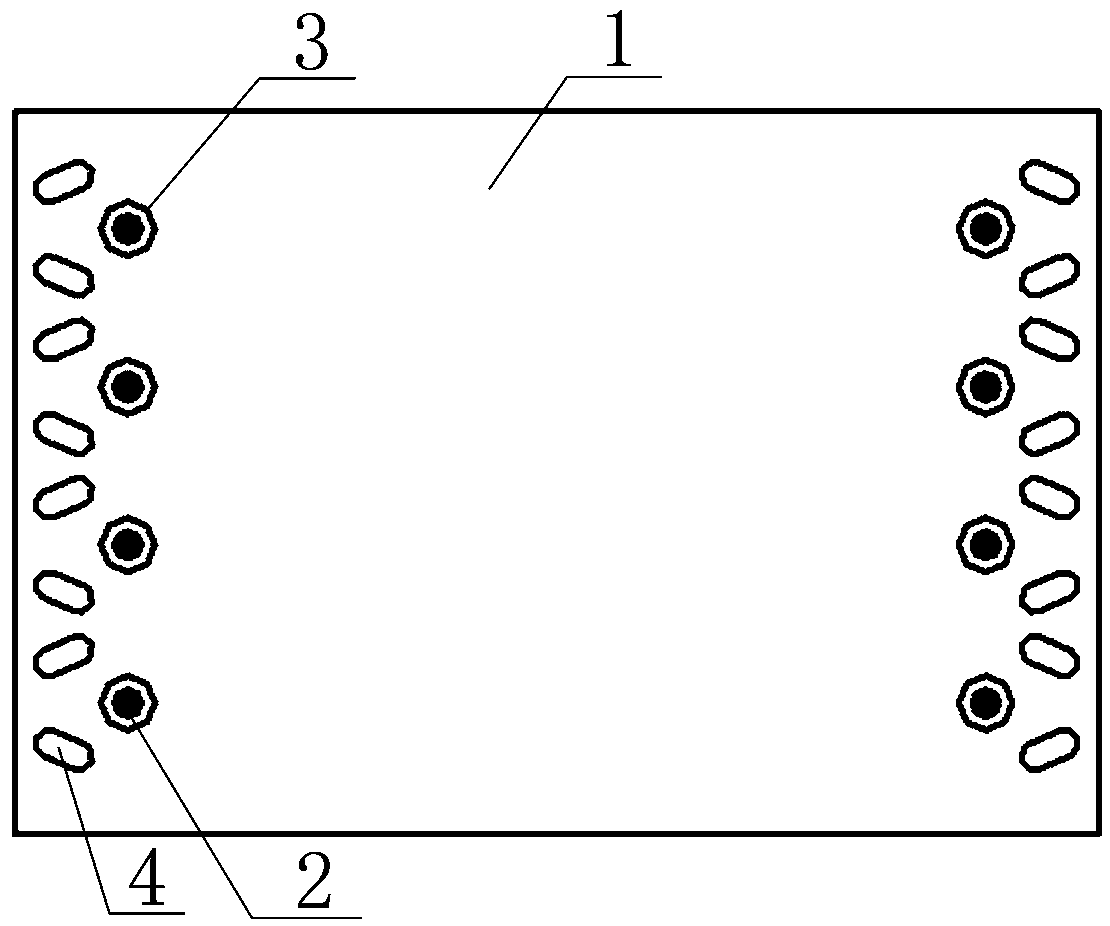

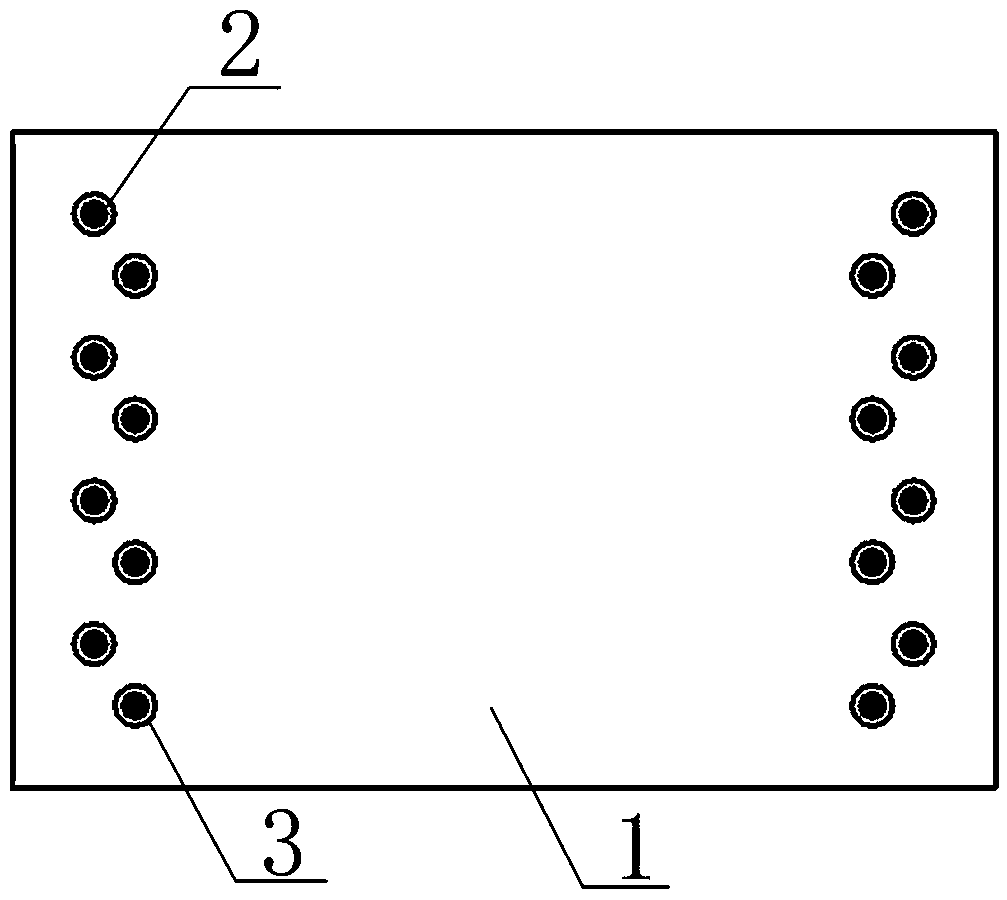

[0047] Such as Figure 1-9 As shown, the connector of this prefabricated sandwich insulation wall includes a connecting plate 1 and an anchoring rib 2; the connecting plate 1 is made of FRP material; wherein, the FRP material is made of reinforced fiber and resin; the connecting The thickness of the plate 1 is less than or equal to 8mm, and the width of the connecting plate 1 is greater than 40mm; on both sides of the connecting plate 1, near the edge, there are holes 3 passing through the anchor ribs 2; In hole 3.

[0048] In this embodiment, the reinforcing fibers are polypropylene fibers and / or glass fibers and / or carbon fibers and / or polyamide fibers and / or aramid fibers and / or basalt fibers.

[0049]In this embodiment, the connecting plate 1 is rectangular as a whole; there are at least one set of holes 3 arranged on both sides of the connecting plate 1; The line shape is uniform and arranged regularly; if there are two or more groups of holes 3 in each group, the holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com