Drilling deviation correction method and device based on following of casing pipe

A technology of deviation correcting device and casing, which is applied in directional drilling and other directions, and can solve problems such as increased drilling rig torque, increased equipment loss, and drill bit deformation, and achieves the effects of increasing strength, ensuring normal slag discharge, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to the analysis of the soil layer and soil quality of a certain ground to be drilled, the soil quality is a sand layer; according to the existing engineering construction experience, it has been clearly affected by the sandy stratum, and the drilling direction is easier to deflect in one direction, so the method described in this embodiment is adopted. The drilling deviation correcting device, select the helical unearthed drill pipe, and drill according to the following deviation correcting method.

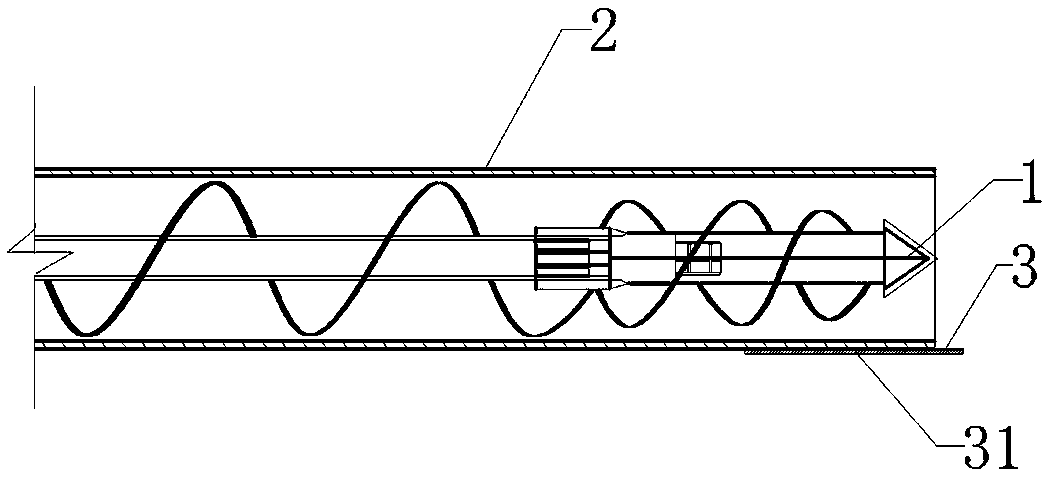

[0044] Such as figure 1 As shown, the drilling deviation correction device based on casing follow-up of the present invention includes a drill bit 1, and a casing 2 located outside the drill bit 1, the diameter of the casing 2 is adapted to the size of the drill bit 1, and the drill bit 1 is front and rear relative to the casing 2. Telescopic movement; the front end of the casing 2 is provided with a steering selection surface 3, the steering selection surface 3 i...

Embodiment 2

[0049] The stratum is a sand and pebble stratum. According to the existing engineering construction experience, it has been clearly affected by the sand and pebble stratum. The direction of the horizontal drilling is easier to deflect upward. The difference between the down-the-hole hammer head and the deviation correction device is:

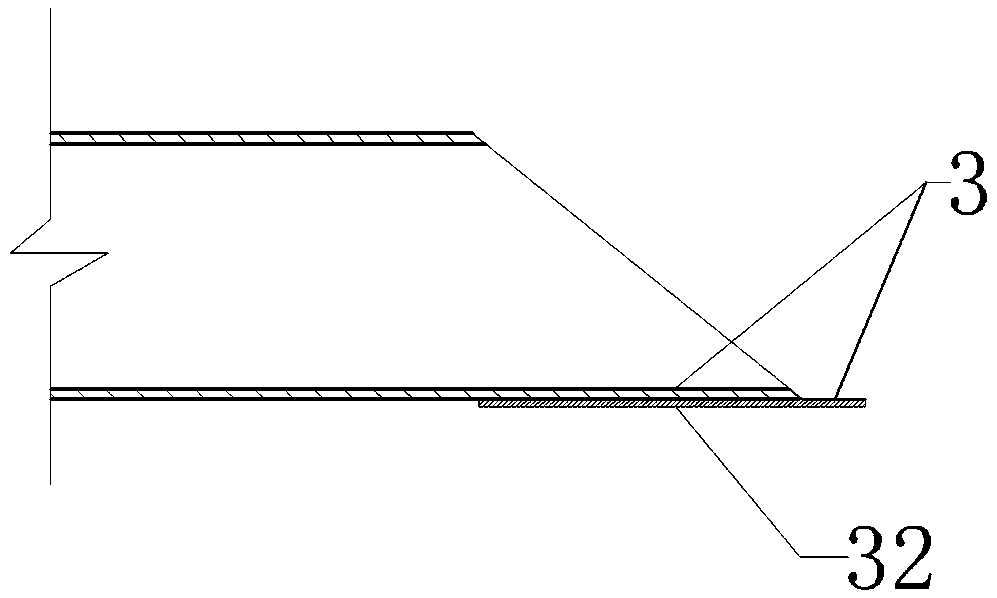

[0050] Such as figure 2 As shown, the oblique nozzle at the front end of the casing 2 is provided with an arc panel 32 at its tip, and one end of the arc panel 32 is attached to the wall of the casing 2, and the other end extends horizontally outwards to extend out of the oblique nozzle. The inner surface of the curved panel 32 and the inner surface of the tip of the oblique nozzle jointly form the steering selection surface 3 .

[0051] The central angle corresponding to the arc panel 32 does not exceed 60°.

[0052] The deviation correction device described in Embodiment 1 and Embodiment 2 is applied in the drilling deviation correction meth...

Embodiment 3

[0062] When a certain stratum and soil structure to be drilled are more complicated, such as a sand layer; then adopt the drilling deviation correction device described in this embodiment, select the three-wing drill bit for use, and carry out drilling according to the following deviation correction method.

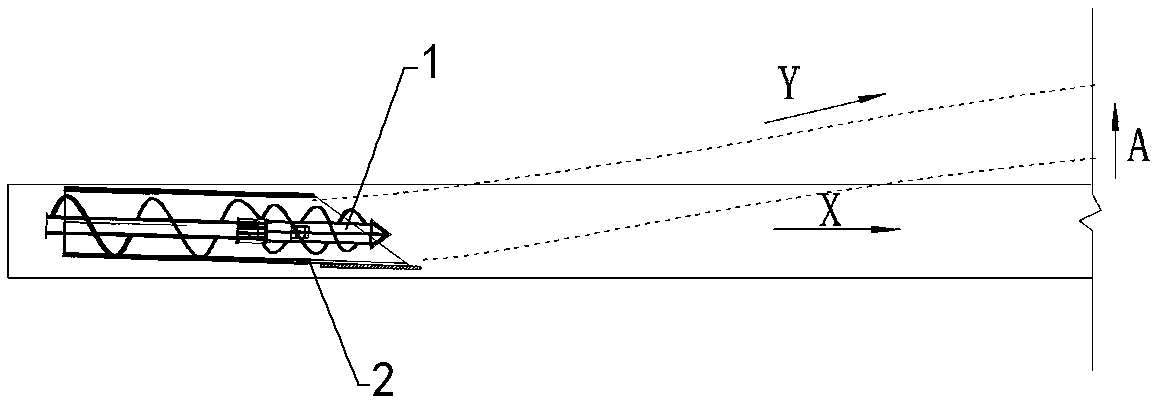

[0063] Such as Figure 4 As shown, the drilling deviation correction device based on casing follow-up of the present invention includes a drill bit 1, and a casing 2 arranged outside the drill bit 1. The diameter of the casing 2 is adapted to the size of the drill bit 1, and the drill bit 1 is relatively Front and back telescopic movement, the pipe diameter of the casing 2 is adapted to the size of the drill bit 1; the front end of the casing 2 is provided with a steering selection surface 3 and a steering maintenance surface 4, and the steering selection surface 3 is located at the mouth of the casing 2 One side, and facing the direction of the central axis of the casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com