Temperature control device and method

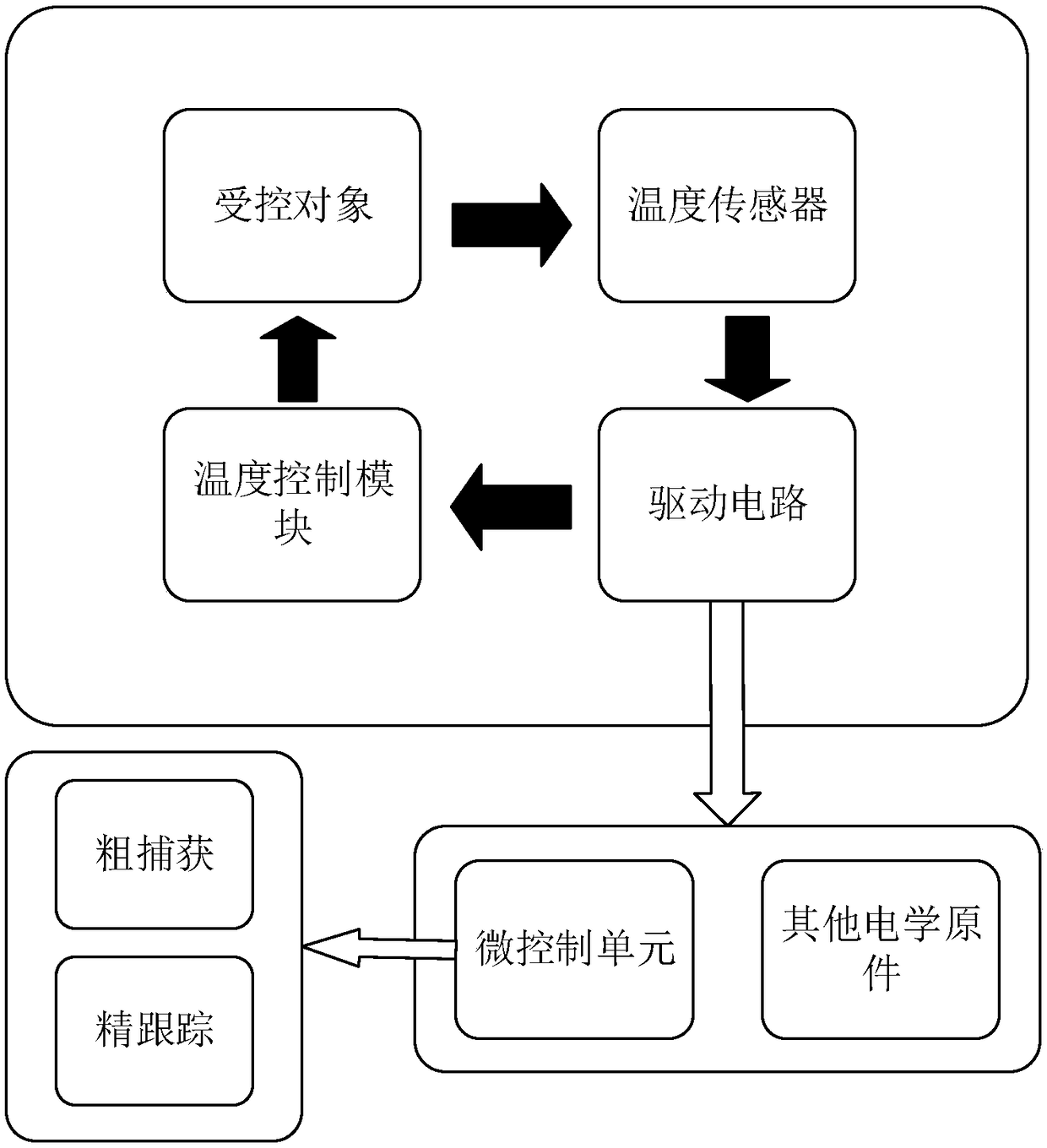

A technology of temperature control device and temperature control method, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc. It can solve the problems of parameter search without fixed means, swing, etc., and achieve stable, timely and efficient temperature control The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

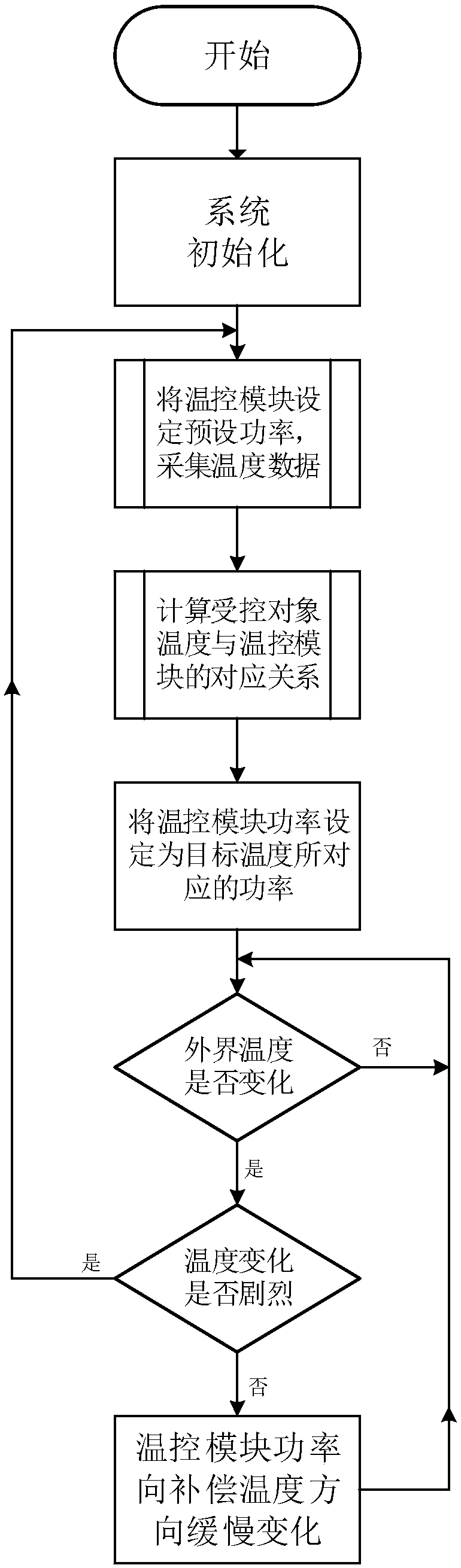

[0041] Take the work of semiconductor lasers as an example. In the actual work of semiconductor lasers, after the system is powered on and initialized, the temperature control module is first ordered to output several fixed powers, such as 10%, 15%, and 30% of full power. The processor records the corresponding laser temperature under these powers; uses the data collected by the temperature sensor to calculate the specific functional relationship between the output power of the temperature control module and the temperature of the laser in the current environment, and then calculates the output of the temperature control module required by the target temperature Power, through the output power of the temperature control module to directly make the laser reach the target temperature; the temperature sensor continues to monitor the laser temperature, if it is stable at the target temperature, the output power of the temperature control module remains unchanged, if the difference b...

specific Embodiment 2

[0042]Take the work of semiconductor lasers as an example. In the actual work of semiconductor lasers, after the system is powered on and initialized, the temperature control module is first ordered to output several fixed powers, such as 10%, 15%, and 30% of full power. The processor records the corresponding laser temperature under these powers; uses the data collected by the temperature sensor to calculate the specific functional relationship between the output power of the temperature control module and the temperature of the laser in the current environment, and then calculates the output of the temperature control module required by the target temperature power, directly make the laser reach the target temperature through the temperature control module; the temperature sensor continues to monitor the laser temperature, if it is stable at the target temperature, the output power of the temperature control module will not change, if the difference between the temperature and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com