Automatic keyboard assembly production line

A production line and keyboard technology, applied to electrical components, electrical switches, circuits, etc., can solve problems such as high defective rate and rework rate, unsmooth production process, unstable product quality, etc., to achieve smooth production process and fast detection speed , the effect of timely rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be further described below in conjunction with the drawings.

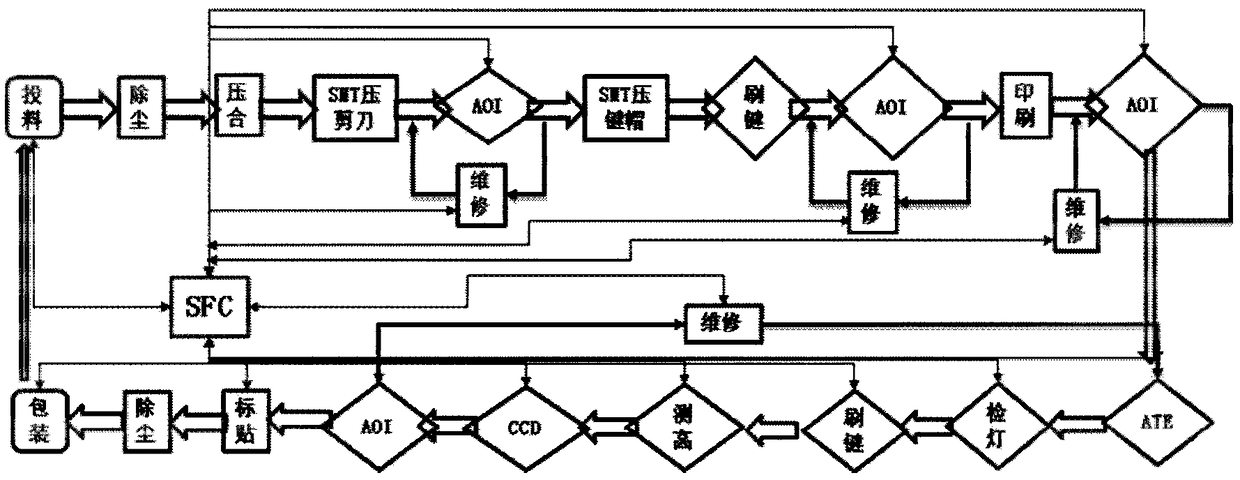

[0020] Such as figure 1 , The keyboard automated assembly production line of the present invention includes a plurality of assembly stations and an assembly control system (SFC system), wherein the assembly station includes a feeding station, a raw material dust removal station, a bottom plate and a circuit board pressing station, and a scissor foot which are sequentially connected Pressing station, keycap pressing station, character printing station, labeling station, finished product dust removal station and packaging station. A material conveyor belt for conveying raw materials or semi-finished products is set between each station; assembly control system and feeding station, labeling station It is electrically connected to the packaging station to collect and record the information of the raw materials entering the assembly line, the attached production ide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com